Device for controlling electron flow and method for manufacturing said device

A technology for controlling electronics and controlling electrodes, which is applied in the manufacture of electrode components, support/installation/spacing/insulation of electrode components, electrostatic control tubes, etc. It can solve problems such as device time degradation, incomplete vacuum, and emitter exposure, and achieve Effects of enhanced control, improved efficiency, and reduced device cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

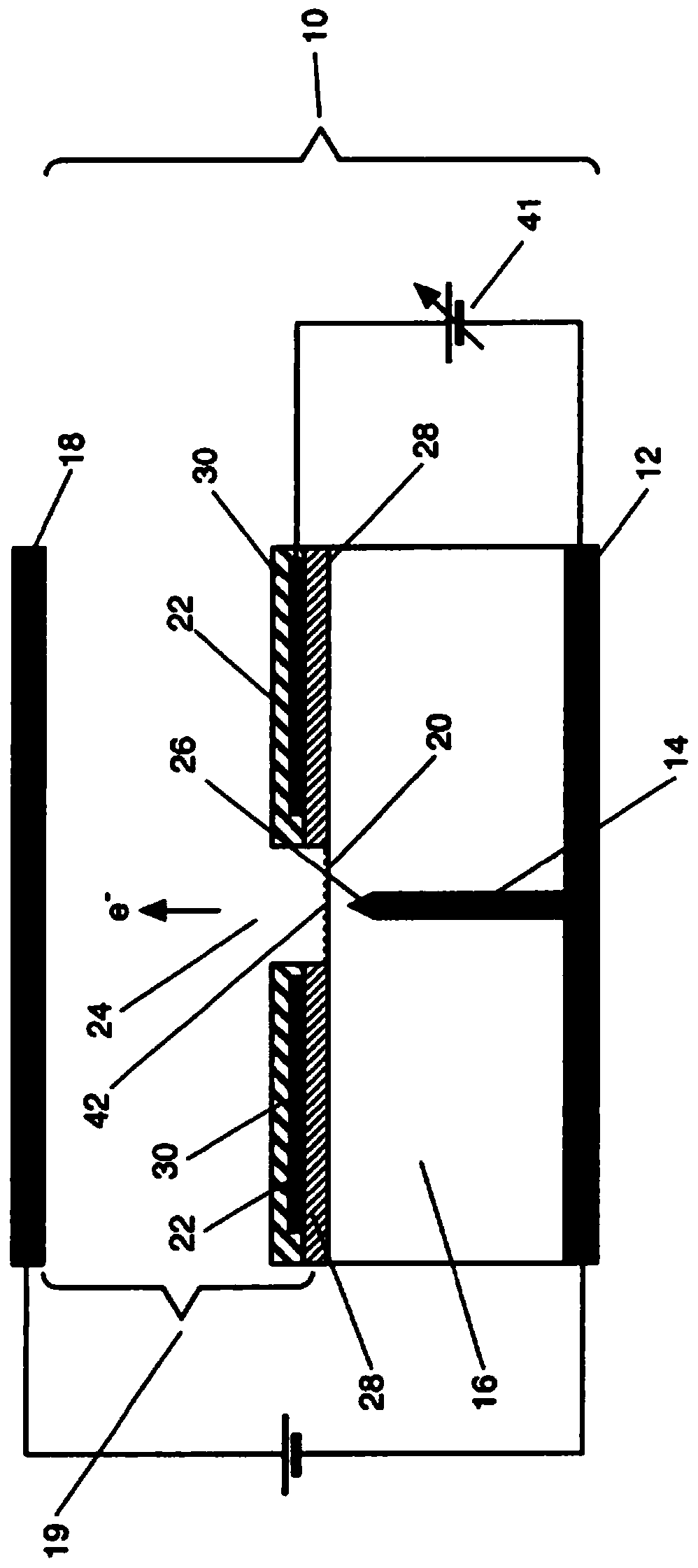

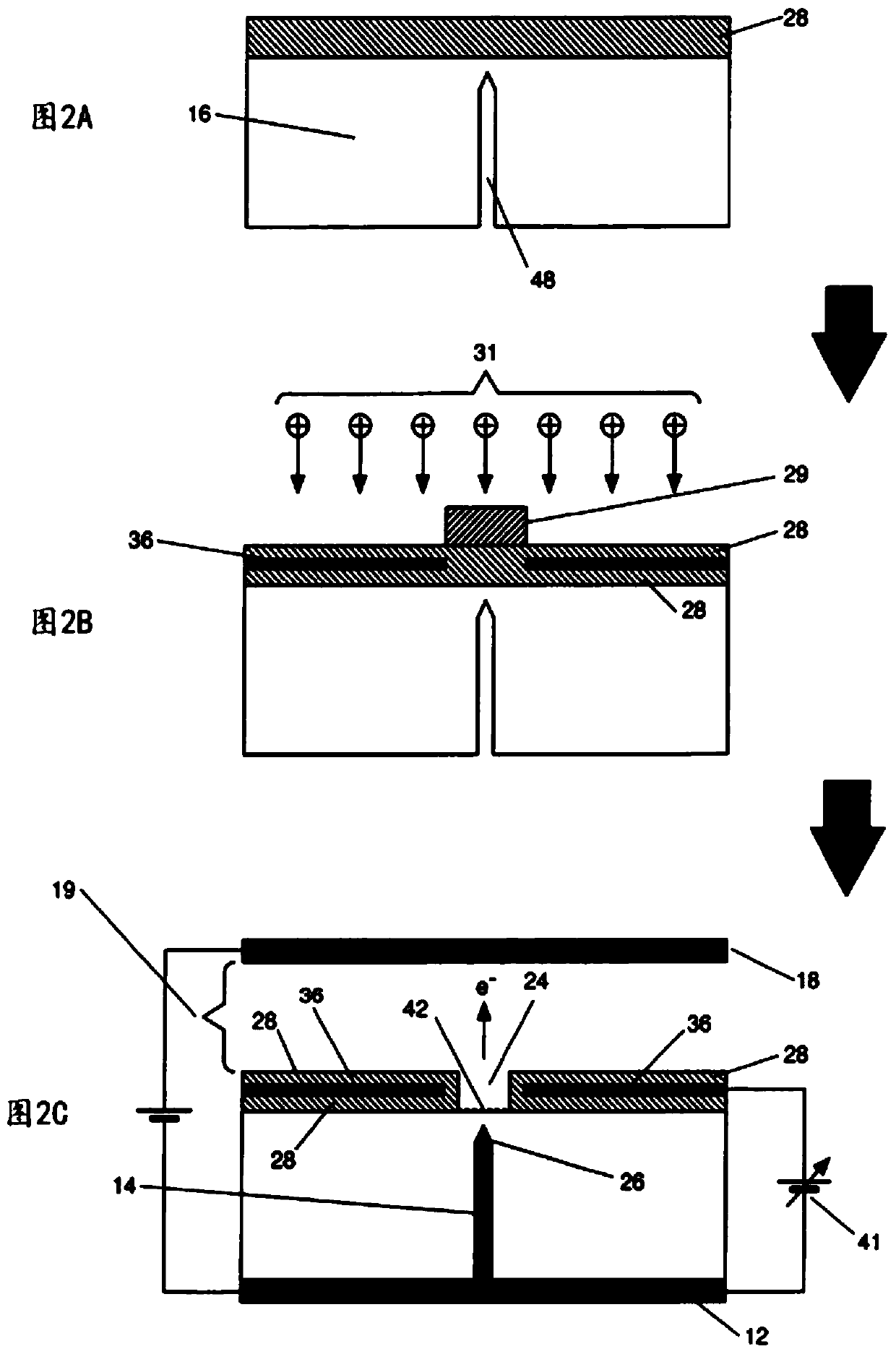

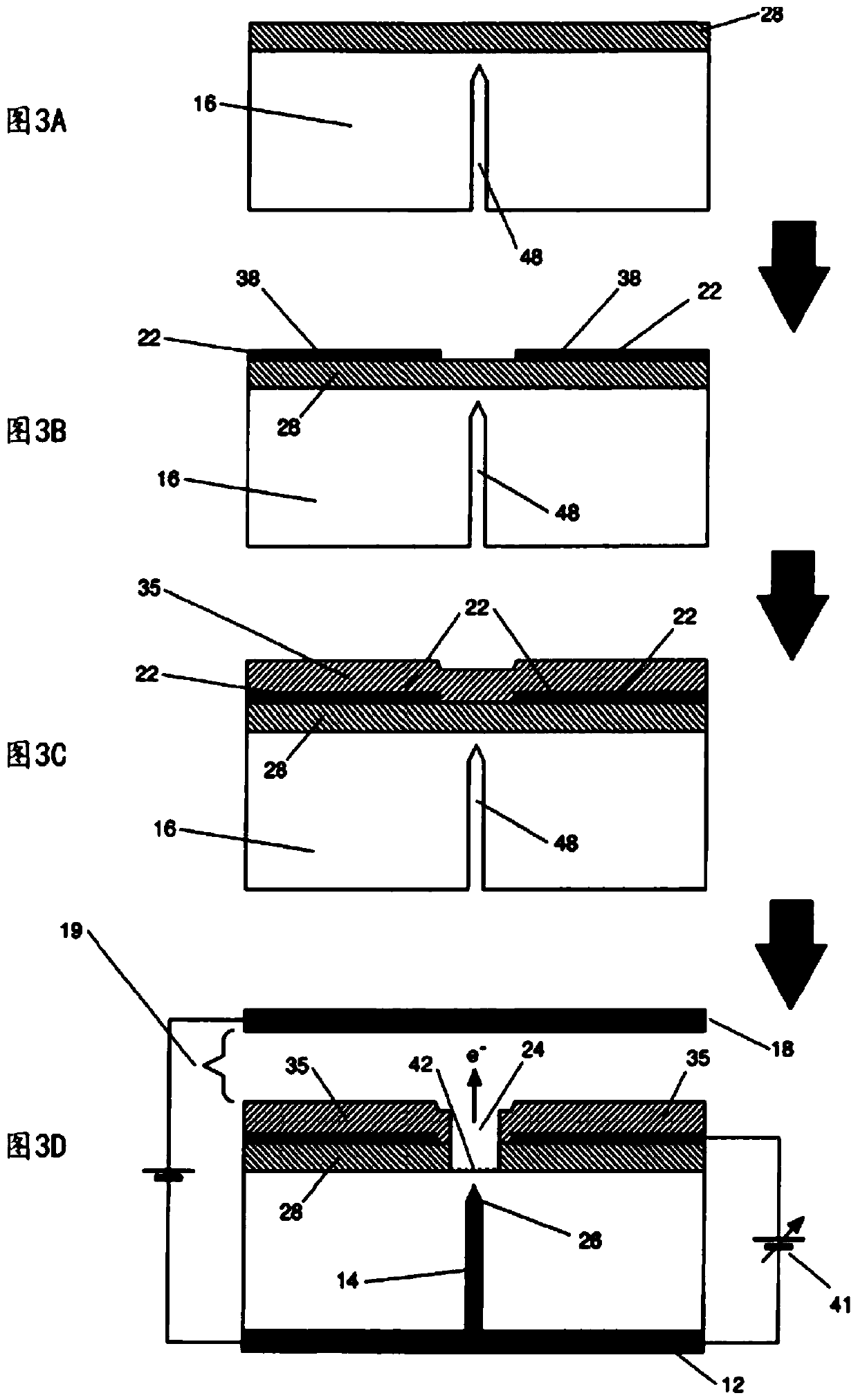

[0114] refer to figure 1 , shows a device 10 for controlling the flow of electrons comprising a cathode 12; an electron source in the form of an elongated electrical conductor 14 embedded in a diamond substrate 16 and in contact and electrical communication with the cathode 12; an anode 18 consisting of A space or void 19 is spaced from the surface 20 of the substrate 16; and a control electrode 22 is disposed on the surface 20 of the substrate. Diamond substrate 16 may comprise intrinsic diamond, nitrogen-doped diamond, or a combination of both. The control electrode shown includes an opening 24 peripherally surrounding an end 26 of the conductor 14 . The exposed portion of surface 20 adjacent end 26 of conductor 14 is treated to exhibit a negative electron affinity. In all figures, the negative electron affinity (NEA) treated surface 42 is indicated by dashed lines. The control electrode 22 is isolated from the substrate 16 using a layer of insulating material 28 and furt...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com