Method for treating high-sodium high-inertinite coal

An inert, high-sodium technology, applied in the field of enrichment of coal microcomponents, can solve the problem of low enrichment rate of microcomponents, achieve the improvement of recovery rate and enrichment ratio of vitrinite, and improve the stability of bubbles , evenly distributed effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

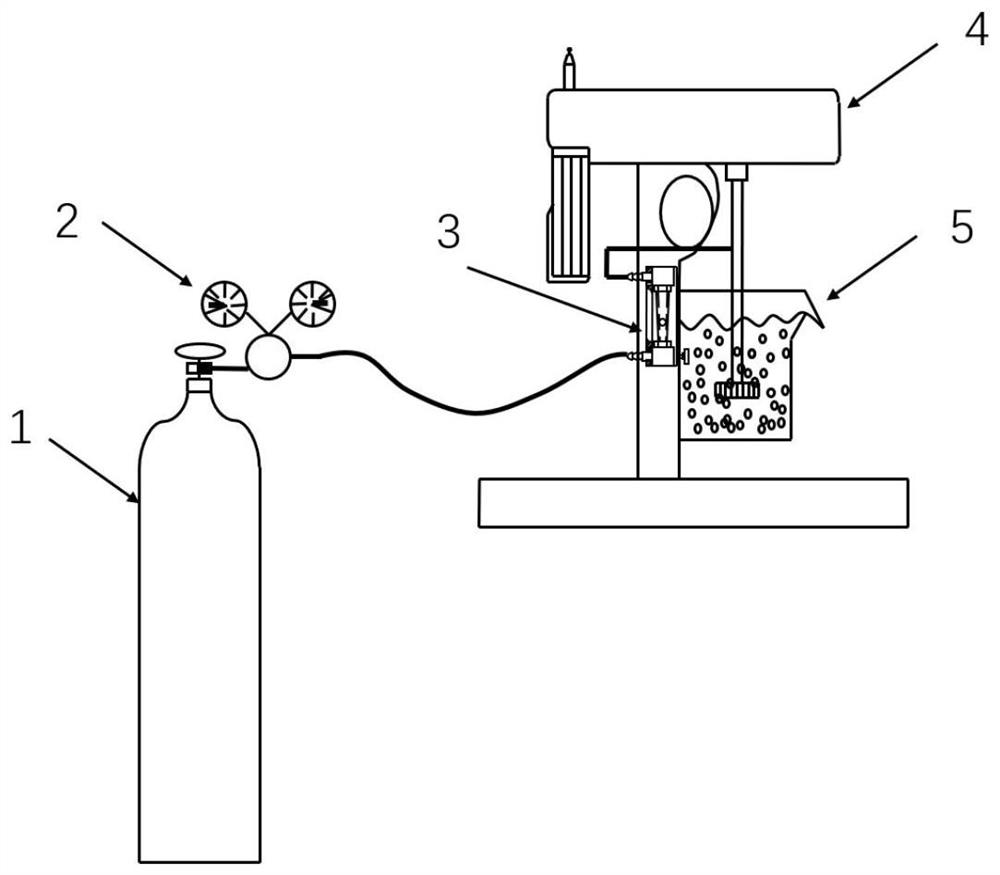

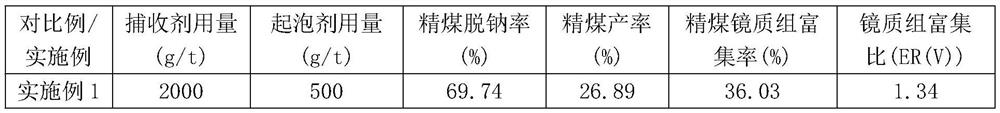

[0034] The high-sodium and high-inertite coal is crushed by a crusher to an average particle size of less than 500 μm, and 80 g of crushed fine-grained raw coal is weighed and poured into the flotation tank 5 and mixed with water to prepare a coal slurry with a concentration of 80 g / L. Selector 4 stirred at a speed of 2000r / min for 30s, and then stirred at a speed of 0.125m 3 / h volume flow from CO 2 Gas cylinder 1 fills flotation cell 5 with CO with a purity of 99.999% 2 gas, and filled with CO 2 While stirring, stop aerating after 3 minutes and add MB compound collector, the dosage of MB compound collector is 2000g / t, after stirring for 2 minutes, add fusel oil foaming agent, the dosage of fusel oil foaming agent is 500g / t , after stirring for 20s with 0.125m 3 / h volume flow from CO 2 Gas cylinder 1 fills flotation cell 5 with CO with a purity of 99.999% 2 Gas and start to scrape bubbles, scrape bubbles for 5min. The flotation clean coal and tailing coal were suction ...

Embodiment 2

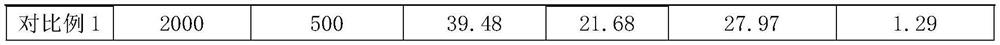

[0042] The high-sodium and high-inertite coal is crushed by a crusher to an average particle size of less than 500 μm, and 80 g of crushed fine-grained raw coal is weighed and poured into the flotation tank 5 and mixed with water to prepare a coal slurry with a concentration of 80 g / L. Selector 4 stirred at a speed of 2000r / min for 30s, and then stirred at a speed of 0.125m 3 / h volume flow from CO 2 Gas cylinder 1 fills flotation cell 5 with CO with a purity of 99.999% 2 gas, and filled with CO 2While stirring, stop aerating after 3 minutes and add MB compound collector. The dosage of MB compound collector is 3000g / t. After stirring for 2 minutes, add 2-octanol foaming agent. The dosage of 2-octanol foaming agent is 1000g / t , after stirring for 20s with 0.125m 3 / h volume flow from CO 2 Gas cylinder 1 fills flotation cell 5 with CO with a purity of 99.999% 2 Gas and start to scrape bubbles, scrape bubbles for 5min. The flotation clean coal and tailing coal were suction ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com