Tuna antistaling agent and usage method thereof

A tuna and antistaling agent technology, which is applied in the direction of preserving meat/fish with chemicals, and preserving meat/fish through freezing/cooling, etc. It can solve the problems of affecting the flavor and taste of aquatic products, unpleasant metallic astringency, rough muscle tissue, etc. Achieve the effect of reducing the loss, reducing the fishy smell and changing the surface potential

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

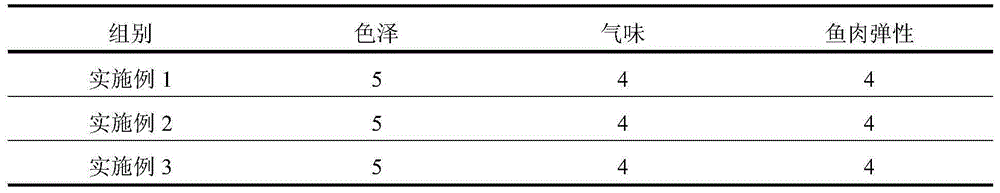

Embodiment 1

[0027] A tuna fresh-keeping agent is composed of the following components in parts by weight: 5 parts of marine low-temperature lysozyme, 3 parts of nisin, 15 parts of modified bentonite, and 300 parts of water.

[0028] Wherein, modified bentonite is prepared by the following steps:

[0029] (1) After crushing, drying and grinding the bentonite raw soil, pass through a 250-mesh sieve;

[0030] (2) Mix the sieved bentonite with 13% hydrochloric acid solution in a mass ratio of 1:3, place in a microwave heater and heat for 6 minutes, and the power of the microwave heater is 800W;

[0031] (3) After heating, filter the mixture, freeze-dry the filter cake, and activate it at 300°C for 30 minutes to obtain modified bentonite.

[0032] The usage method of the tuna fresh-keeping agent configured by the above-mentioned components comprises the following steps:

[0033] (1) After cleaning the fresh tuna, soak it in the tuna preservative for 4 minutes, then take it out and drain it, ...

Embodiment 2

[0036] A tuna fresh-keeping agent is composed of the following components in parts by weight: 8 parts of marine low-temperature lysozyme, 5 parts of nisin, 18 parts of modified bentonite, and 300 parts of water.

[0037] Wherein, modified bentonite is prepared by the following steps:

[0038] (1) After crushing, drying and grinding the bentonite raw soil, pass through a 300-mesh sieve;

[0039] (2) Mix the sieved bentonite with 15% hydrochloric acid solution in a mass ratio of 1:3.5, place in a microwave heater and heat for 7 minutes, and the power of the microwave heater is 850W;

[0040] (3) After heating, filter the mixture, freeze-dry the filter cake, and activate it at 320°C for 40 minutes to obtain modified bentonite.

[0041] The usage method of the tuna fresh-keeping agent configured by the above-mentioned components comprises the following steps:

[0042] (1) After cleaning the fresh tuna, soak it in the tuna preservative for 5 minutes, then take it out and drain it...

Embodiment 3

[0045] A tuna fresh-keeping agent is composed of the following components in parts by weight: 10 parts of marine low-temperature lysozyme, 8 parts of nisin, 20 parts of modified bentonite, and 300 parts of water.

[0046] Wherein, modified bentonite is prepared by the following steps:

[0047] (1) After crushing, drying and grinding the bentonite raw soil, pass through a 300-mesh sieve;

[0048] (2) Mix the sieved bentonite with 18% hydrochloric acid solution in a mass ratio of 1:4, place in a microwave heater and heat for 8 minutes, and the power of the microwave heater is 900W;

[0049] (3) After heating, filter the mixture, freeze-dry the filter cake, and activate it at 350°C for 45 minutes to obtain modified bentonite.

[0050] The usage method of the tuna fresh-keeping agent configured by the above-mentioned components comprises the following steps:

[0051] (1) After cleaning the fresh tuna, soak it in the tuna preservative for 6 minutes, then take it out and drain it,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com