PECVD gas shower head, film forming chamber and working method

A gas shower head and film-forming cavity technology, applied in gaseous chemical plating, metal material coating process, coating and other directions, can solve the problems of reduced dissociation efficiency, slow cleaning speed, etc. Improved uniformity, high commercial value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be described in detail below in conjunction with specific embodiments shown in the accompanying drawings.

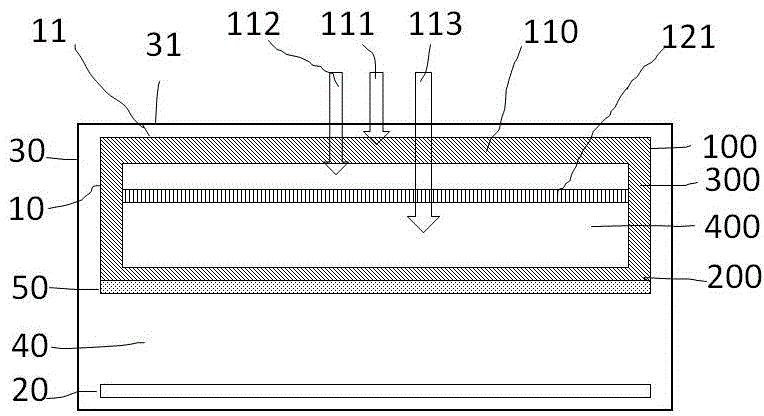

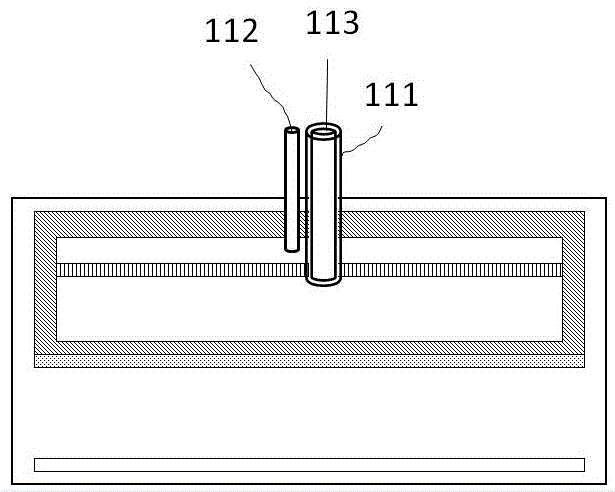

[0032] figure 1 Shown is a schematic structural view of a PECVD film-forming chamber in an embodiment of the present invention. The PECVD film-forming chamber includes an upper electrode 10 , a lower electrode 20 , and a cavity 30 . The upper electrode 10 is connected to a radio frequency power supply, and a plasma discharge region 40 is formed between the lower electrode 20, which is the film forming region of the PECVD film forming chamber, and the upper surface 11 of the upper electrode is in contact with the cavity top wall The distance range of the inner surface 31 is less than or equal to 3 mm, so as to prevent generation of parasitic plasma.

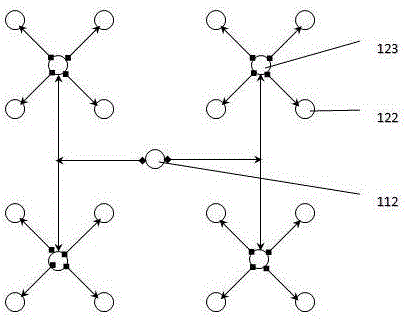

[0033] The upper electrode 10 is also connected to a gas source, and the gas source includes process gas or cleaning gas to provide the required gas to the plasma discharge area, so the upp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com