Contact type deformation heat box for elasticizer

A deformation heat box and contact technology, applied in textiles and papermaking, etc., can solve the problems of poor thermal insulation effect, high heat loss rate, and high thermal conductivity of thermal insulation materials, so as to improve thermal insulation effect, reduce thermal conductivity, and save energy effect of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Below the present invention will be further described in conjunction with the embodiment in the accompanying drawing:

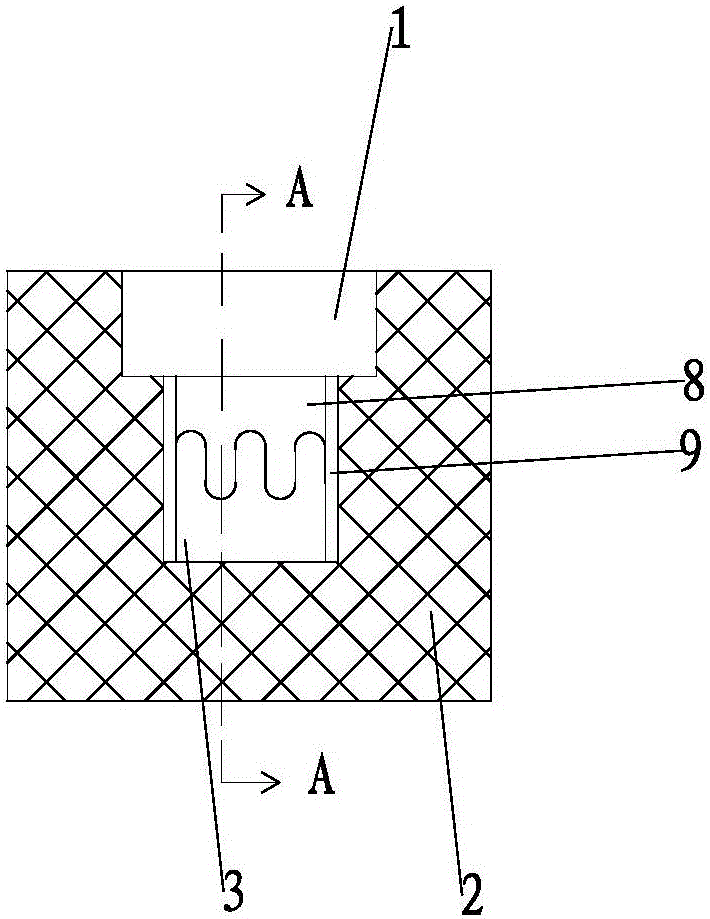

[0019] like Figure 3~6 As shown, the present invention mainly comprises hot box 1, hot box main body 2 and hot rail 3, and the middle part of hot box main body 2 is provided with hot rail installation chamber 6, and arc-shaped hot rail 3 is set in the hot rail installation chamber 6.

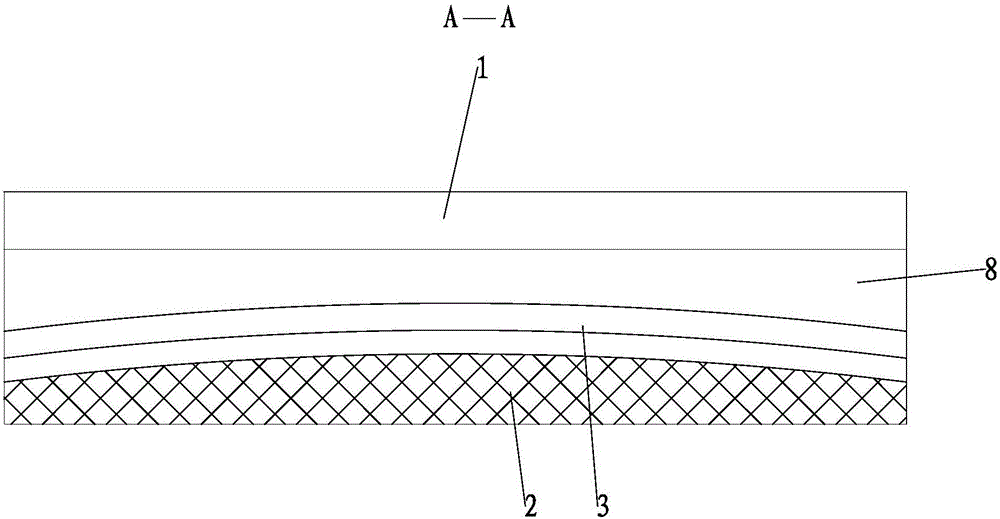

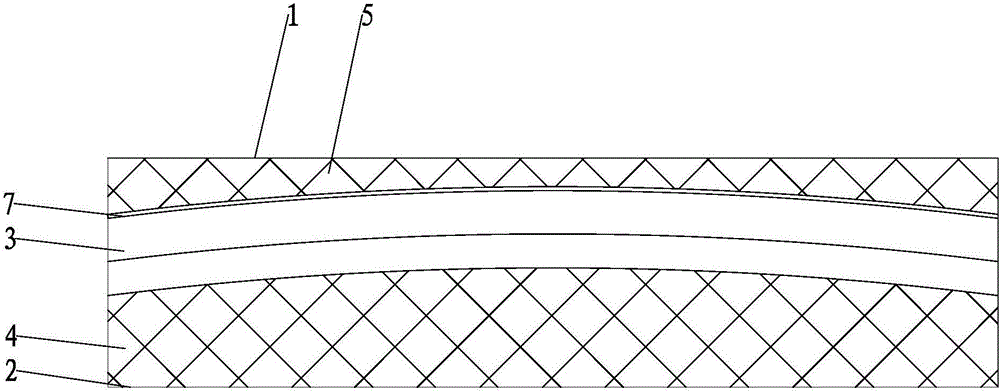

[0020] The upper end surface of the heating box main body 2 coincides with the upper end surface of the heating rail 3, so that the upper end surface of the heating box main body 2 is close to the upper end surface of the heating rail 3, and a certain space is left between the upper end surface of the heating box main body 2 and the convex surface of the heating rail 3. The gap 7, the range of the gap 7 is 0~10mm.

[0021] A heat insulation layer 4 is provided between the outer wall of the heat box main body 2 and the heat rail 3, and the heat insulation layer 4 is fil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com