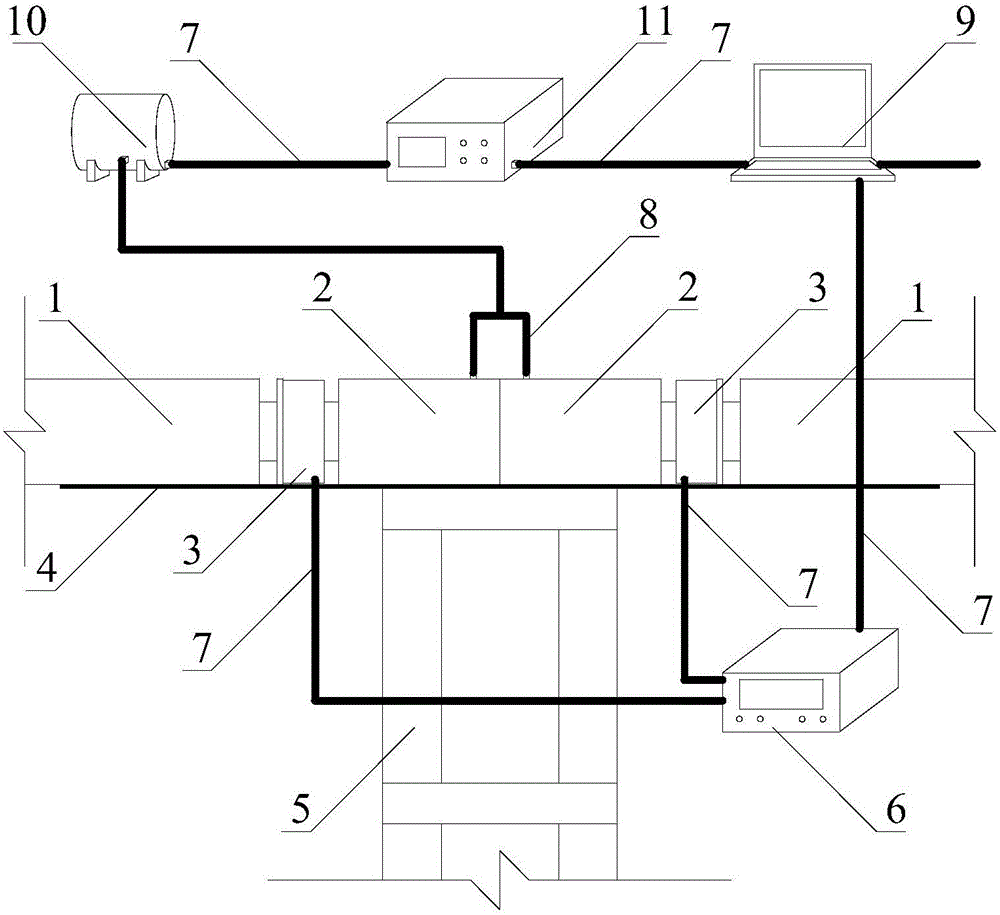

Foundation pit supporting method capable of automatically controlling horizontal displacement of underground diaphragm wall

An underground diaphragm wall and foundation pit support technology, applied in excavation, infrastructure engineering, construction, etc., can solve the problem of inability to achieve dynamic adjustment, reduce the risk of foundation pit deformation, reduce horizontal displacement, and the system is simple reliable results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

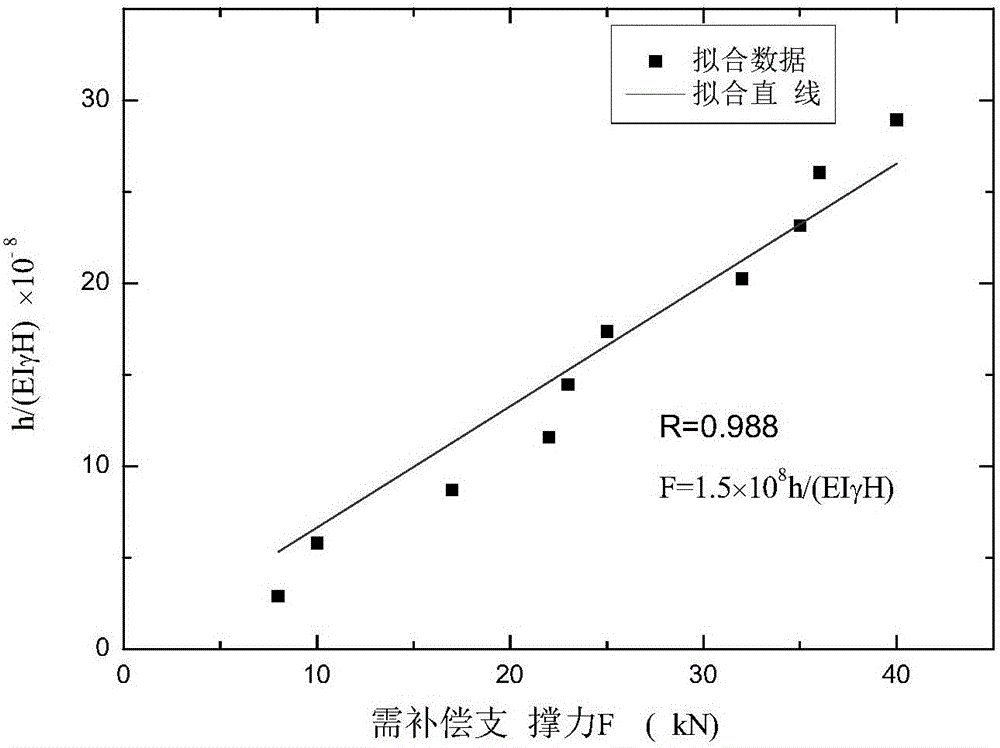

[0039] A foundation pit is located in a soft soil area, and the groundwater level is 0.000m. The size of the foundation pit is 50m×10m, and the elevation of the bottom of the foundation pit is -5m. The foundation pit enclosure adopts an underground diaphragm wall, the thickness of which is 0.5m, and the stiffness of the diaphragm wall per unit length is 120000kN m 2 , the elevations of the top and bottom of the underground diaphragm wall are 0.000m and -8.0m, respectively. Before the foundation pit is excavated, the well point dewatering method is used to carry out pre-dewatering in the foundation pit.

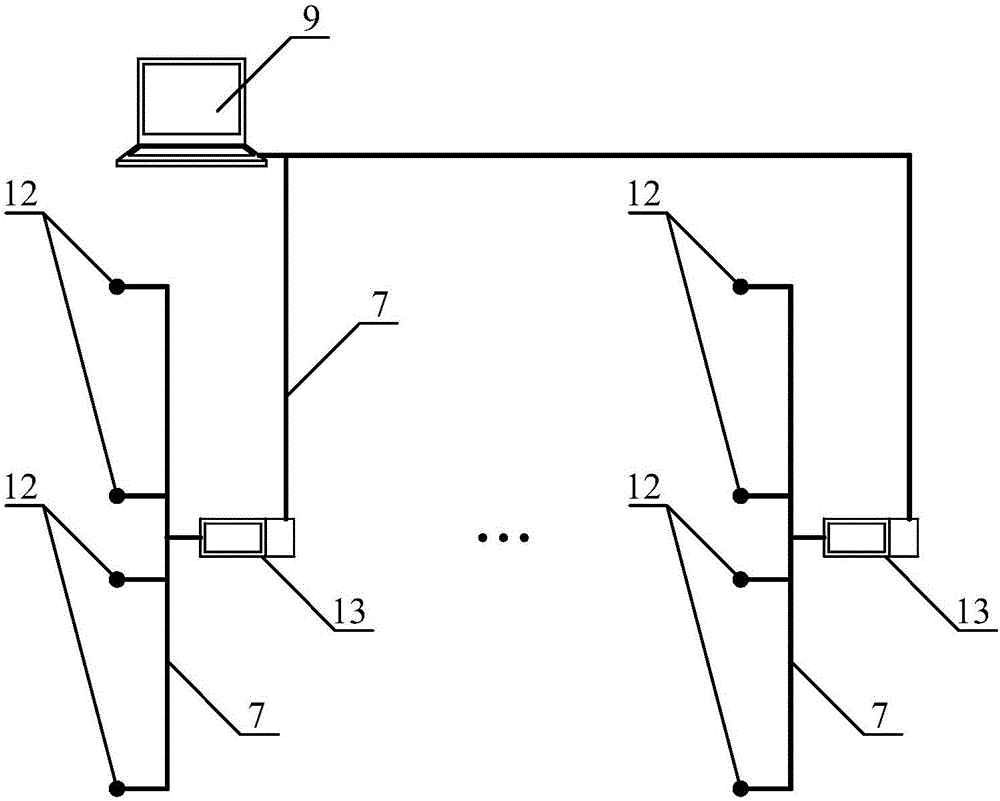

[0040] Step 1: Determined by the size of the foundation pit, it is necessary to arrange a set of horizontal supports every 5m along the length of the foundation pit, a total of 9 sets;

[0041] At the midpoint of each group of horizontal supports, a lattice column with a section size of 400mm×400mm welded by four 100mm×100mm×7mm angle steels and several 400mm×70mm×7mm strips...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Outer diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com