Buckling restrained energy-consuming support structure restrained by adopting GFRP angle steel

A technology for preventing buckling energy consumption and supporting structure, applied in the direction of earthquake resistance, building components, etc., can solve the problems of not easy separation of restraint parts, damage to restraint parts, damage to restraint parts, etc., to achieve convenient and economical installation, easy replacement, and improved service life. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

[0029] The present invention provides a buckling-resistant energy-dissipating support structure constrained by GFRP angle steel, and its processing steps and specific implementation methods are as follows:

[0030] Processing steps:

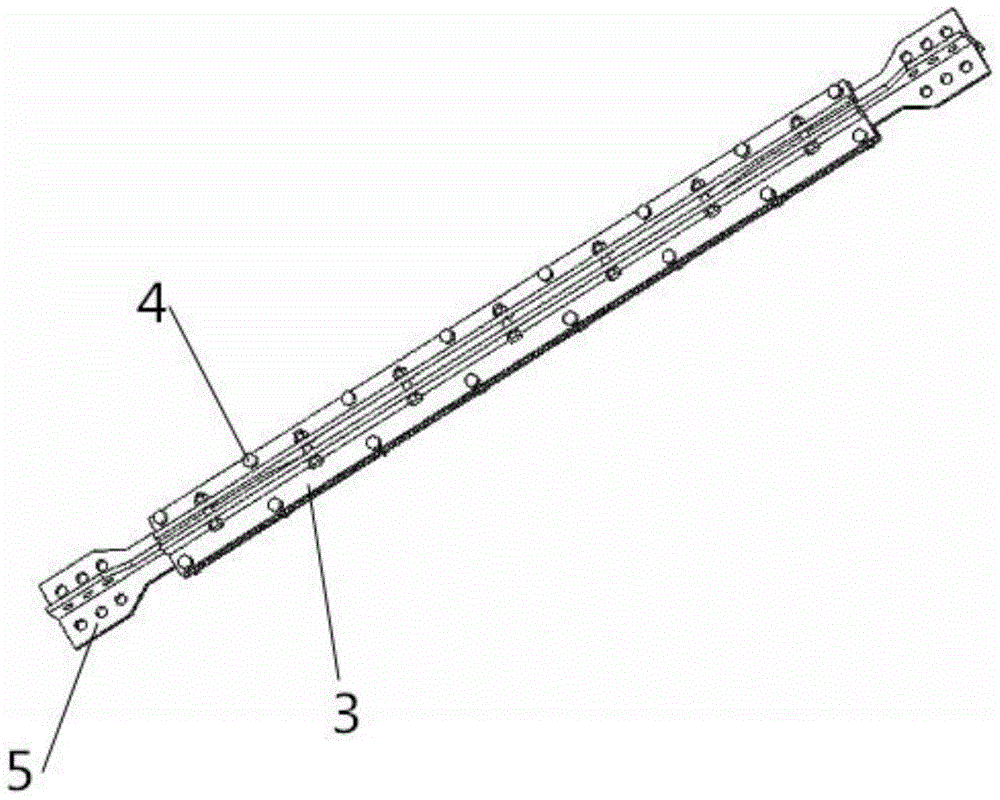

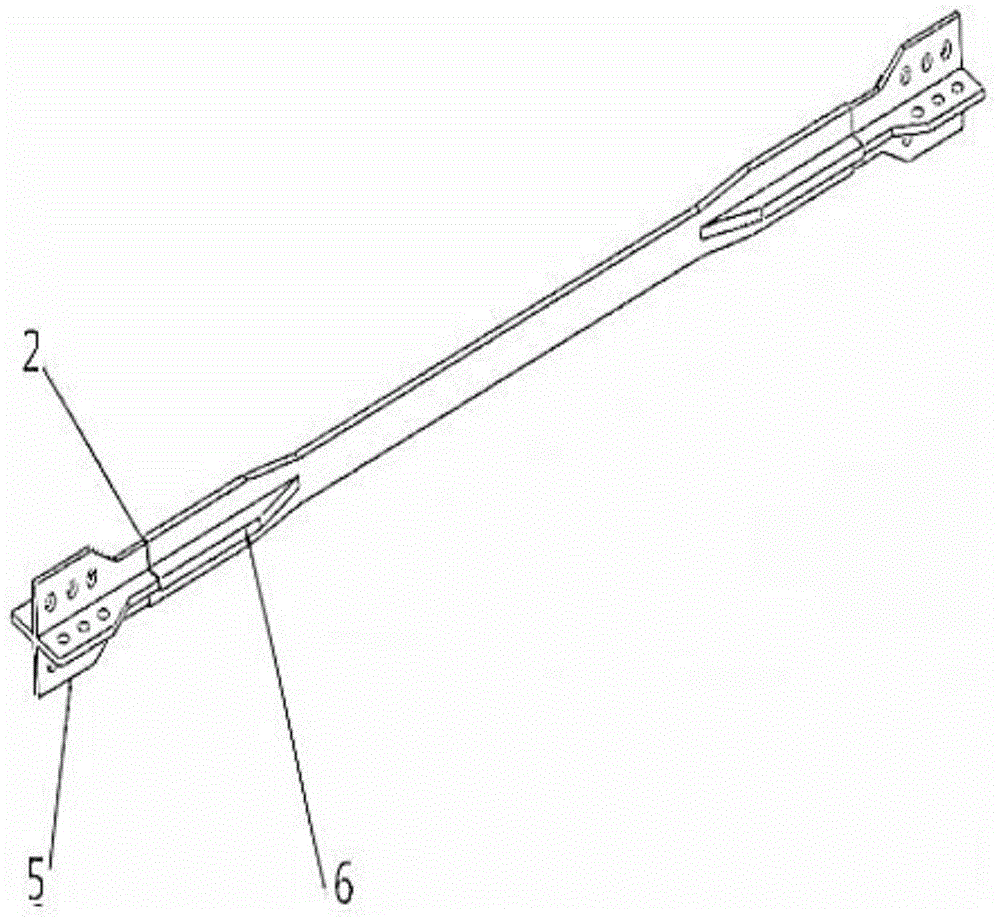

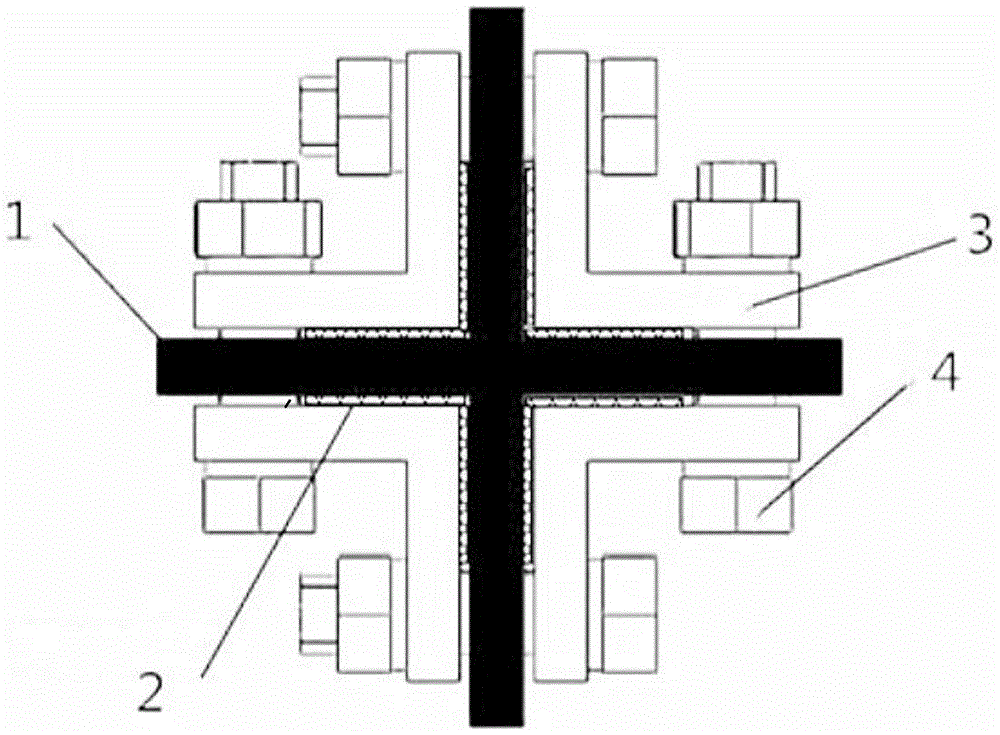

[0031] 1. Prepare the core plate 1 and weld the stiffener plate 6: Weld the stiffener plate 6 on the constrained non-yielding section of the core plate of the buckling-resistant braced core unit to obtain the core plate 1 of the buckling-resistant braced core unit core plate with stiffener plates; 2. Preparation of GFRP angle steel 3: Prepare four identical GFRP angle steels 3 of appropriate size according to the buckling-resistant support core unit core plate 1 with stiffened ribs obtained in step 1; 3. Preparation of GFRP high-strength bolts 4: use GFRP material Prepare a certain number of high-strength bolts 4; four, drill holes on the GFRP angle steel 3: according to the GFRP angle steel 3 and GFRP high-strength bolt 4 obtained in steps two a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com