Piston body oil chamber sealing device

A sealing device and plug body technology, which is applied to the sealing device of the engine, piston, liquid variable capacity machinery, etc., can solve the problem that the piston and cylinder cannot be completely sealed, and achieve the purpose of reducing temperature, preventing leakage and realizing efficient utilization. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

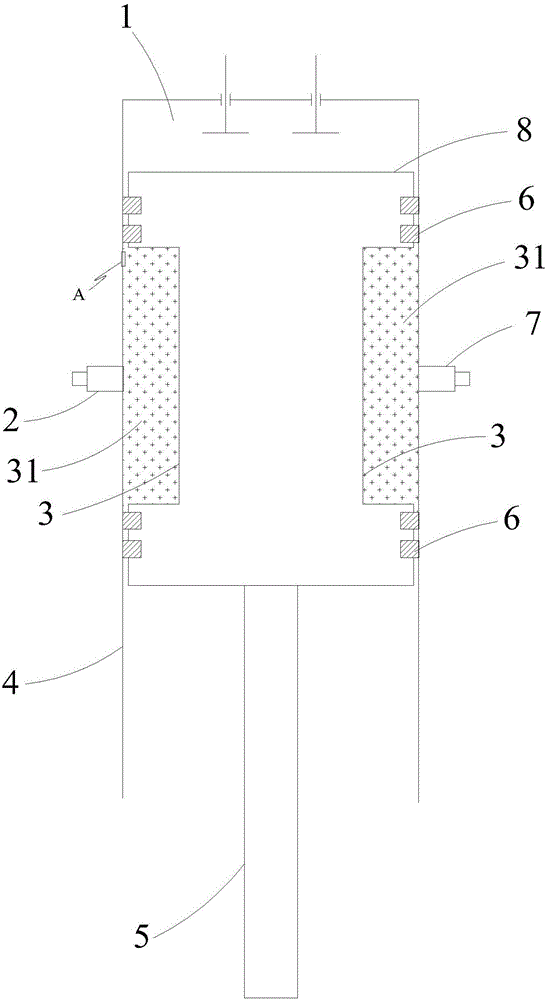

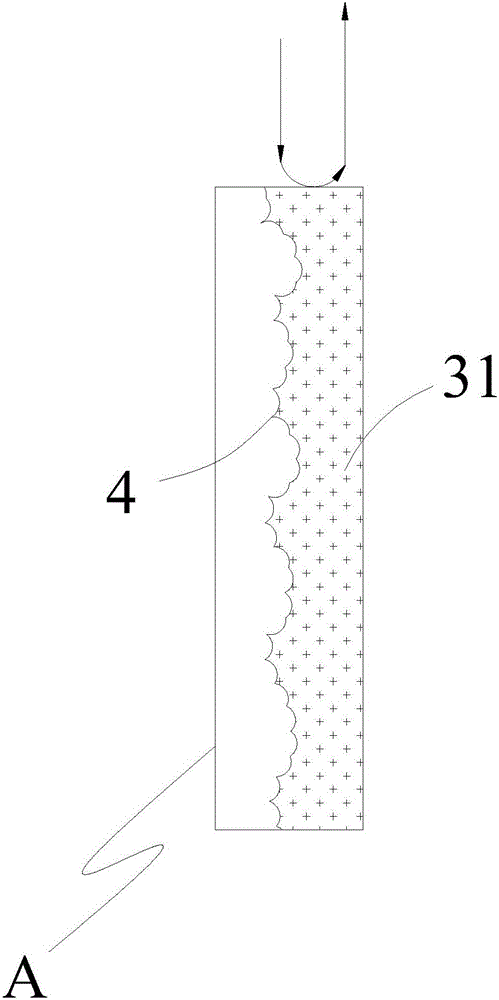

[0036] Such as figure 2 and image 3 As shown, the plug body oil cavity sealing device of this embodiment includes a cylinder 4 and a plug body 8 located in the cylinder 4 and matched with the cylinder 4 , the connection between the plug body 8 and the side wall of the cylinder 4 An annular sealing oil groove 3 is provided between them, and the annular sealing oil groove 3 is provided on the side wall of the plug body 8 . The annular sealing oil groove 3 is filled with sealing oil 31 . Two piston rings 6 are respectively arranged on the upper and lower sides of the annular sealing oil groove 3 , and the piston rings 6 are located between the plug body 8 and the side wall of the cylinder 4 . The side wall of the cylinder 4 is provided with an oil inlet 2 and an oil outlet 7 that are opposite and communicated with the annular seal oil groove 3, and the oil inlet 2 and the oil outlet 7 are respectively located in the ring seal. The middle of oil tank 3.

[0037] The lower en...

Embodiment 2

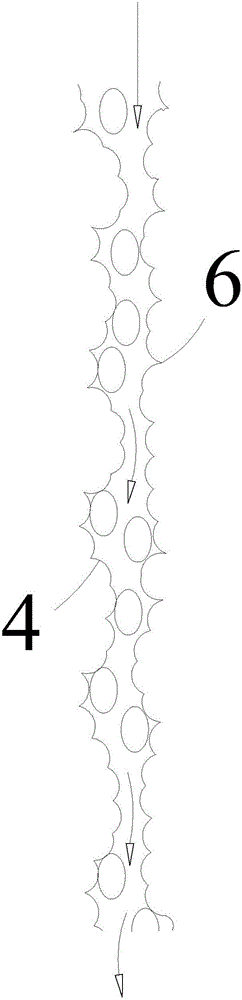

[0040] Such as Figure 4 As shown, the plug body oil cavity sealing device of this embodiment includes a cylinder 4 and a plug body 8 located in the cylinder 4 and matched with the cylinder 4 , the connection between the plug body 8 and the side wall of the cylinder 4 Two annular sealing oil grooves 3 are arranged between them, and the two annular sealing oil grooves 3 are sequentially opened on the side wall of the plug body 8 from top to bottom. The annular sealing oil groove 3 is filled with sealing oil 31 . Two piston rings 6 are respectively arranged on the upper and lower sides of each annular sealing oil groove 3 , and the piston rings 6 are located between the plug body 8 and the side wall of the cylinder 4 . The side wall of the cylinder 4 is provided with an oil inlet 2 and an oil outlet 7 that are opposite and communicated with the annular seal oil groove 3, and the oil inlet 2 and the oil outlet 7 are respectively located in the ring seal. The middle of oil tank ...

Embodiment 3

[0045] Such as Figure 5 As shown, the plug body oil cavity sealing device of this embodiment is used in a natural gas compressor, and includes a sealing sleeve 4 and a moving shaft 9 located in the sealing sleeve 4 and cooperating with the sealing sleeve 4. The moving shaft Two annular sealing oil grooves 3 are arranged between 9 and the side wall of the sealing sleeve 4 , and the two annular sealing oil grooves 3 are sequentially provided on the side wall of the moving shaft 9 from top to bottom. The annular sealing oil groove 3 is filled with sealing oil 31 . Two piston rings 6 are respectively arranged on the upper and lower sides of each annular sealing oil groove 3 , and the piston rings 6 are located between the moving shaft 9 and the side wall of the sealing sleeve 4 . The side wall of the sealing sleeve 4 is provided with an oil inlet 2 and an oil outlet 7 opposite to the annular sealing oil groove 3, and the oil inlet 2 and the oil outlet 7 are respectively located ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com