Potential energy recovery and reuse system and method for high-level tapping machine

A potential energy recovery and tapping machine technology, which is applied to fluid pressure actuation system components, mechanical equipment, fluid pressure actuation devices, etc., can solve problems such as wasting energy, increasing leakage probability, and oil temperature rise, and achieves reduction Unstable system pressure, reduced throttling loss, and reduced output energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

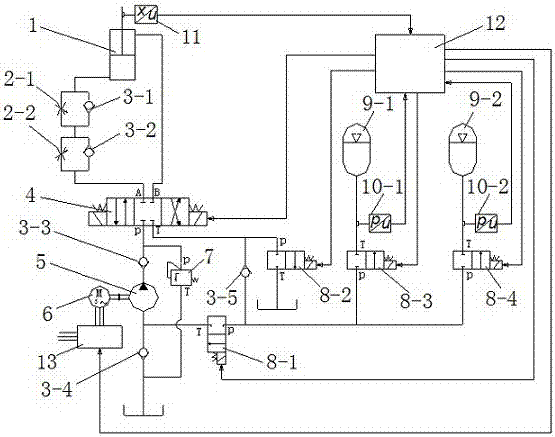

[0026] Such as figure 1As shown, a potential energy recovery and reuse system for a high-level tapping machine includes a hydraulic cylinder 1, a first adjustable flow valve 2-1, a second adjustable flow valve 2-2, a first one-way valve 3-1, Second one-way valve 3-2, third one-way valve 3-3, fourth one-way valve 3-4, fifth one-way valve 3-5, three-position four-way electromagnetic reversing valve 4, hydraulic pump 5, Three-phase asynchronous motor 6, overflow valve 7, first two-position two-way electromagnetic reversing valve 8-1, second two-position two-way electromagnetic reversing valve 8-2, third two-position two-way electromagnetic reversing valve 8 -3. The fourth two-position two-way electromagnetic reversing valve 8-4, the first accumulator 9-1, the second accumulator 9-2, the first pressure sensor 10-1, and the second pressure sensor 10-2 , displacement sensor 11, controller 12, frequency converter 13;

[0027] The connection method is as follows: the oil outlet of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com