Combustion chamber structure of circulating fluidized bed boiler

A circulating fluidized bed and furnace structure technology, applied in the field of super boilers, can solve the problems of difficulty in popularization, difficulty in inspection and maintenance of the inner ring heating surface, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

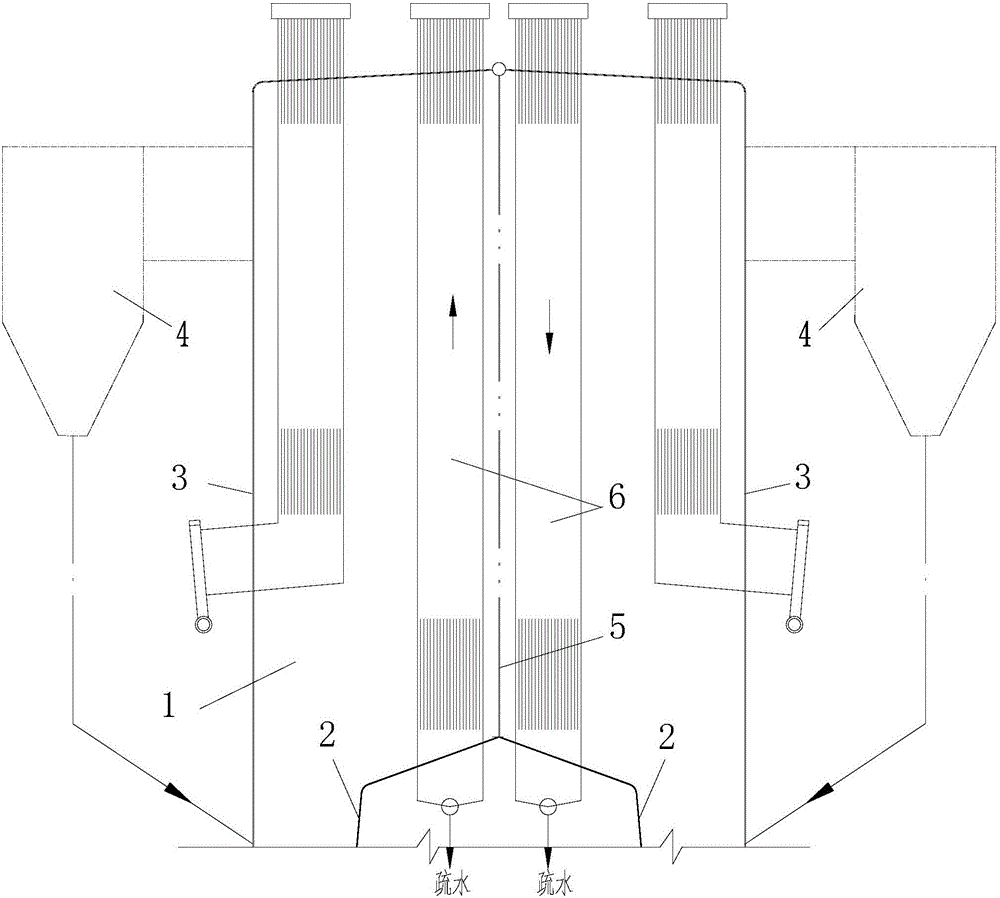

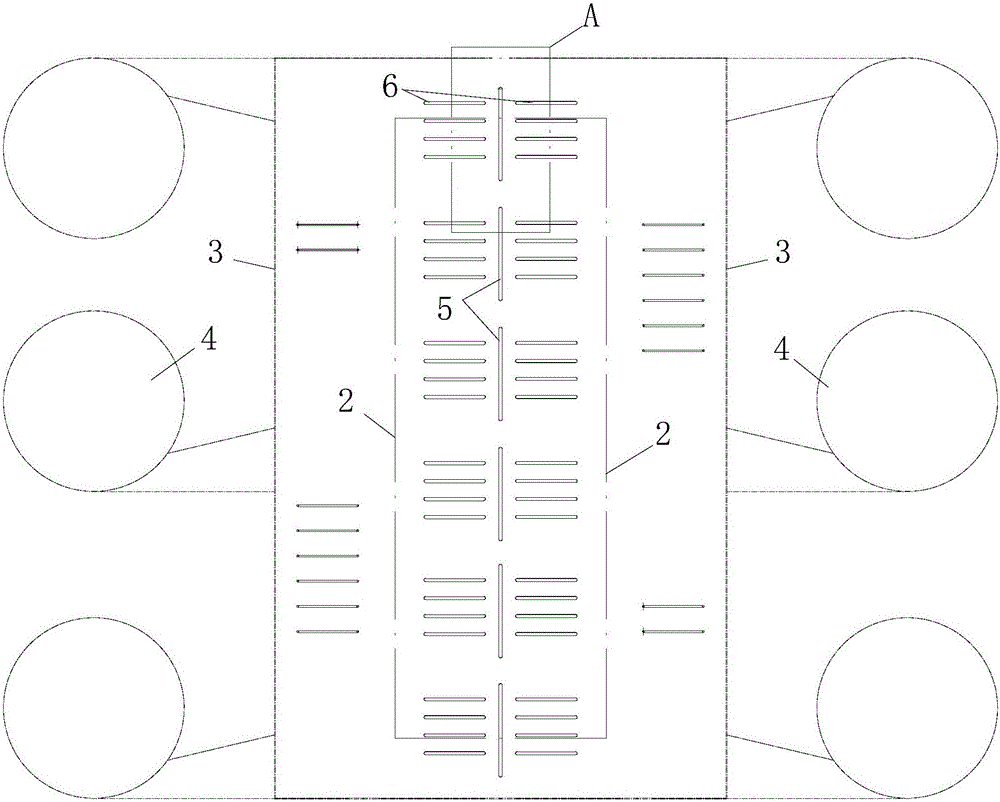

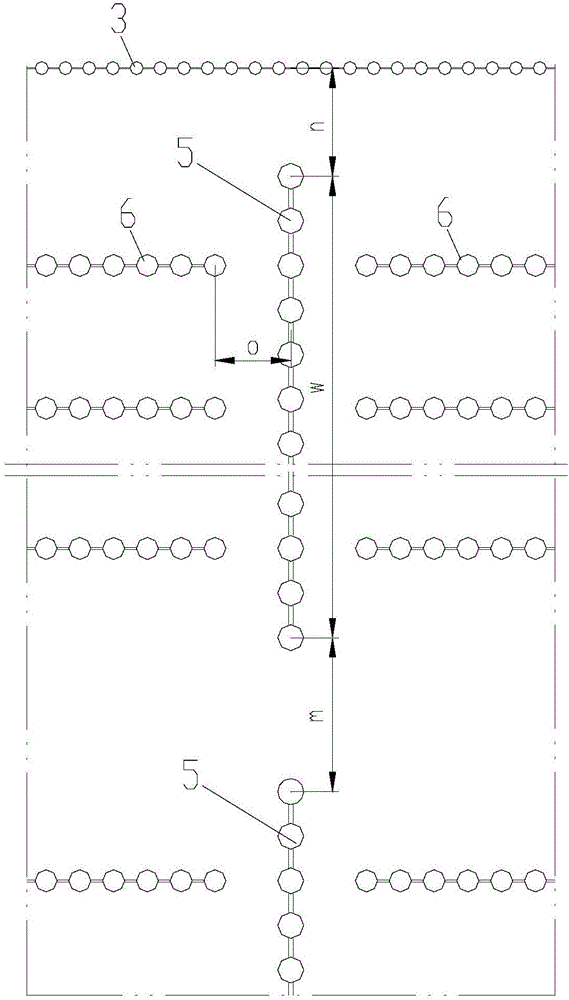

[0033] Such as Figure 1-4 as shown, Furnace structure of a circulating fluidized bed boiler , the air distribution plate and the lower furnace are annular structures, the inner ring and outer ring of the furnace 1 are polygonal, and the number of outer ring edges and inner ring edges is not less than 4, as shown in this embodiment, the inner ring and outer ring are rectangular. The inner ring water cooling wall 2 tubes and the outer ring water cooling wall 3 tubes in the lower part of the furnace 1 are not connected, the inner ring water cooling wall 2 tubes are inclined upward and inward, and the position of the boiler centerline at the junction of the dense phase area and the dilute phase area of the furnace 1 is merged into A number of double-sided heated water-cooled tube panels 5, that is, each water-cooled tube panel is located in the same plane, and the water-cooled tube panel extends vertically upwards from the furnace ceiling to pass through the furnace 1, and ...

Embodiment 2

[0035] Such as Figure 5 As shown, this embodiment is basically the same as Embodiment 1, and the difference is that: the inner ring water-cooled wall intermediate header 7 corresponding to the double-sided heated water-cooled tube panel 5 is not provided, and the two inner ring water-cooled walls on both sides of the boiler centerline 2 The tubes are merged into a double-sided heated water-cooled tube-panel tube through the Y-shaped tube 8, which solves the problem of a certain lack of enthalpy in the inlet of the tube-panel required by the once-through boiler.

Embodiment 3

[0037] Such as Figure 6-9 As shown, this embodiment is basically the same as Embodiment 1, and the difference is that the inner ring water-cooled wall intermediate header 7 corresponding to the double-sided heated water-cooled tube panel 5 is not provided, and two or more inner headers on the same side of the boiler center line The ring water wall tube passes through the goblet tube 9 ( Figure 6 、 7 ) or rake tube 10 ( Figure 8 、 9 ) into a double-sided heated water-cooled tube-panel tube, which solves the problem of a certain lack of enthalpy in the inlet of the tube-panel required by the once-through boiler.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com