Nondestructive positioning method for GOI failure point and GOI failure analysis method

A locating method and failure point technology, applied in the direction of analyzing materials, using wave/particle radiation for material analysis, measuring devices, etc., can solve the problems of GOI failure point damage, time-consuming, etc., to reduce production time, improve accuracy and success. The effect of high-speed, high-precision positioning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The principles and features of the present invention are described below in conjunction with the accompanying drawings, and the examples given are only used to explain the present invention, and are not intended to limit the scope of the present invention.

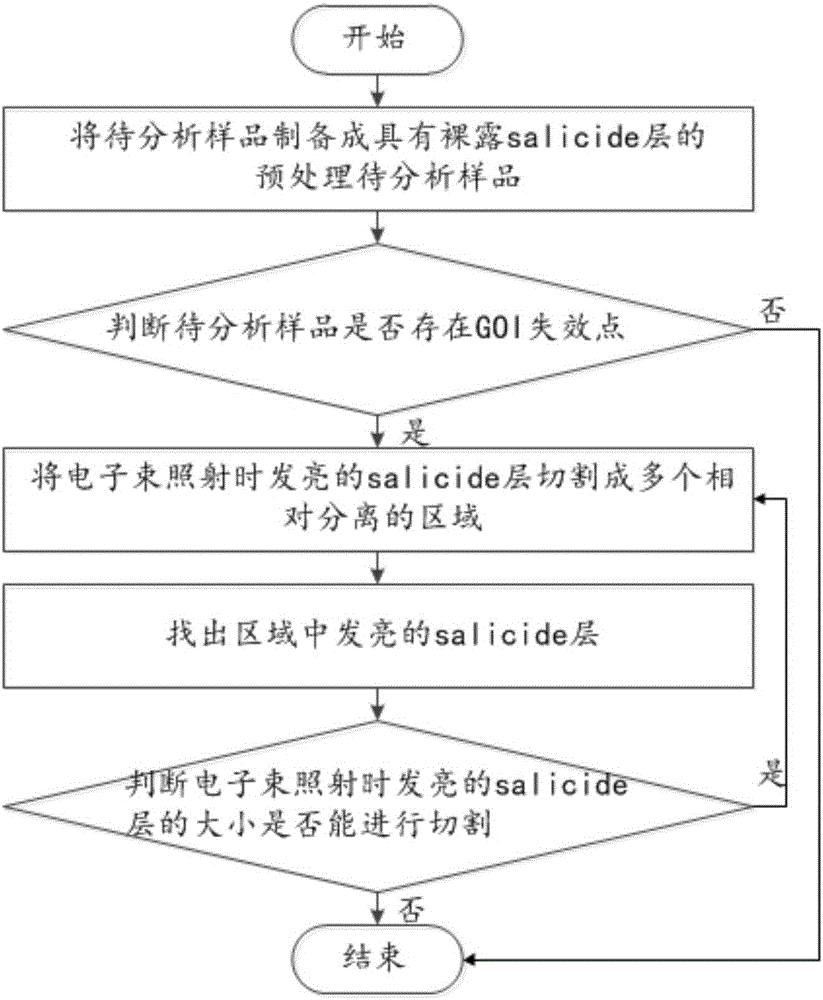

[0028] Such as figure 1 As shown, a GOI failure point non-destructive positioning method includes the following steps:

[0029] Step 1, remove the metal interconnection layer of the sample to be analyzed, and obtain the pretreated sample to be analyzed with a bare salicide layer; the removal of the metal interconnection layer of the sample to be analyzed adopts mechanical grinding and / or chemical etching.

[0030] Step 2, based on the PVC method, use electron beams to irradiate the salicide layer of the pretreated sample to be analyzed, and observe whether it is shiny; if yes, then there is a GOI failure point in the sample to be analyzed, and perform step 3; State that there is no GOI failure point in the sample t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com