Ultra-short pulse fiber laser system using graphene saturable absorber to lock mode

A fiber laser, ultra-short pulse technology, used in the field of lasers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below with reference to the accompanying drawings and in conjunction with the embodiments.

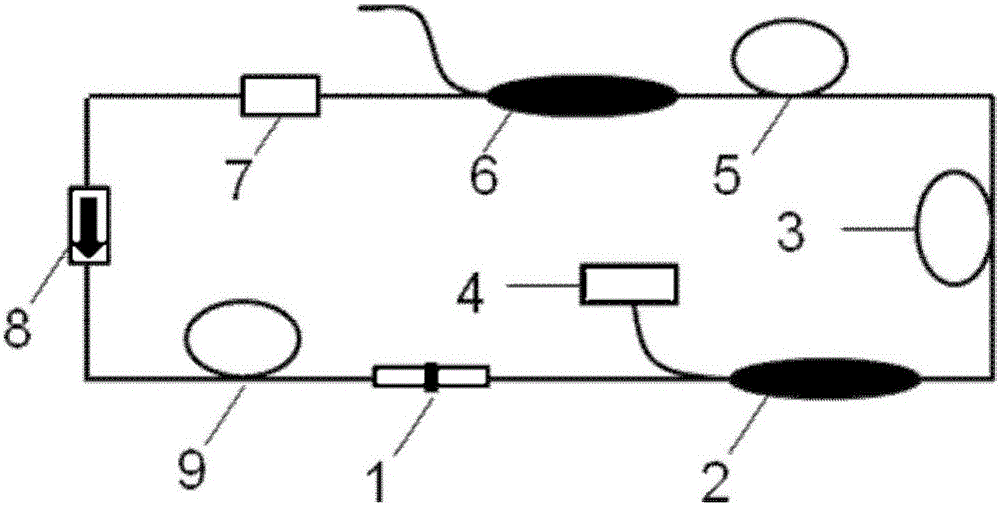

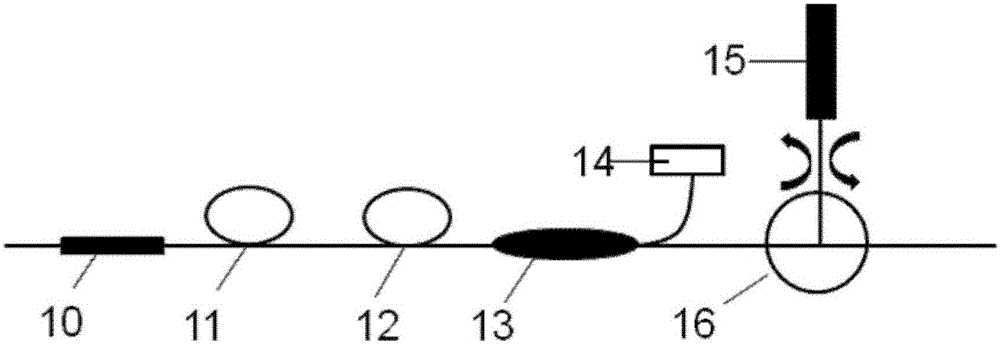

[0017] refer to figure 1 and figure 2 , the ultra-short pulse fiber laser system of the present invention is mode-locked with a graphene saturable absorber, which is mainly composed of a ring fiber laser seed source and a chirped amplifier. The desired ultrashort pulse (femtosecond pulse) is obtained after amplification and dechirping.

[0018] Specific as figure 1 As shown, the ring fiber laser seed source includes a graphene saturable absorber 1, a wavelength division multiplexer 2 connected to an LD pump 4, a Yb-doped active fiber 3, a first passive fiber 5, an output coupler 6, a band Pass filter 7, optical isolator 8 and the second passive fiber 9, graphene saturable absorber 1, wavelength division multiplexer 2, Yb-doped active fiber 3, the first passive fiber 5, output coupler 6, The bandpass filter 7, the optical isola...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com