A permanent magnet coupling speed regulating device with axial meshing area adjustment

A technology of meshing area and permanent magnetic coupling, which is applied in the field of coupling speed regulation, can solve problems such as high technical requirements, insufficient system reliability, and low energy conversion efficiency, and achieve the effect of broad market application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] The technical solutions of the present invention will be described in detail below in conjunction with the accompanying drawings, so that those skilled in the art can understand the present invention more clearly, but the protection scope of the present invention is not limited thereby.

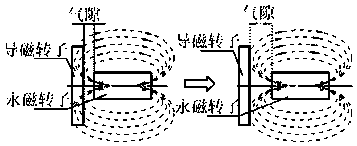

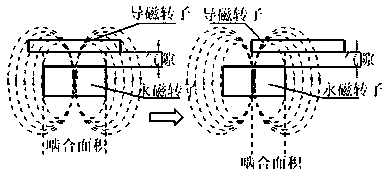

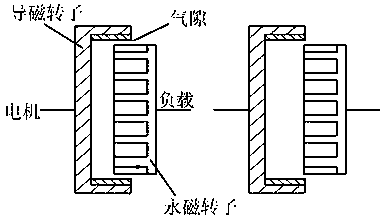

[0043] At first explain the technical principle of the present invention, simultaneously in conjunction with appendix figure 1 to attach image 3 , with figure 1 It is the schematic diagram of the existing air-gap adjustable permanent magnet speed governor. The adjustment of the speed is realized by adjusting the air gap between the magnetically permeable rotor and the permanent magnet rotor. The adjustment mechanism of the air gap is relatively complicated and based on The accuracy of speed adjustment by air gap adjustment is low. The permanent magnetic coupling speed regulating device innovatively proposed by the present invention realizes the adjustment of the rotational speed by ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com