Extruded flakes and manufacturing method thereof

A flake, food-grade technology for cereal flakes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0034] The preparation conditions for producing direct sheet from the direct sheeting method are different from those for producing rolled sheet. In a preferred embodiment, the direct tablet may be made from a carbohydrate material combined with one or more of a non-cereal starch component, protein component, lipid component, fortifying ingredient, and flavoring ingredient Mix together. The mixed raw material is then cooked in an extruder at a temperature of 100°C to 180°C and a water content of 5% to 30%. The mixed raw material is then cut directly from the extrusion die at a cutting frequency in the range of 200Hz to 3000Hz and dried to a moisture content of 2% to 8%. The cutting frequency can be selected as described above.

[0035] Dry the extruded product. This drying step can be performed using an infrared (IR) heater or by hot air drying. Typically the product is placed on a mesh belt passing through the IR dryer so that IR radiation is emitted from above and below ...

Embodiment

[0061] extrusion conditions

[0062] The flour compositions shown in the following examples were fed into a twin-screw extruder (Clextral Evolum 88) configured as follows: L / D=16 (length of processing zone / outer diameter of screw), screw and feed The overall length of the barrel is 1408 mm. The screw configuration is shown in Table 1.

[0063] Water is added to the second barrel of the extruder to bring the moisture content of the dough inside the extruder to 15% to 22%. The temperature profile in the continuous barrel was 20°C / 20°C / 80°C / 100°C / 120°C / 140°C to cook the dough. The dough reaches a temperature of 140°C to 150°C and a pressure of 30 bar to 120 bar at the extrusion die, which causes instantaneous moisture flash and puffing of the extruded product. The extruded product is cut to produce a puffed extruded product with a moisture content between 9% and 12%.

[0064] Screw length(mm)

[0065] Table 1

Embodiment 1

[0076] Example 1: Directly extruded sheet

[0077] Direct tablets were prepared using Formulation A, Formulation B or Formulation C with extrusion parameters and cutting parameters as described in Table 1 and Table 3.1.

[0078]

[0079]

[0080] chart 3.1

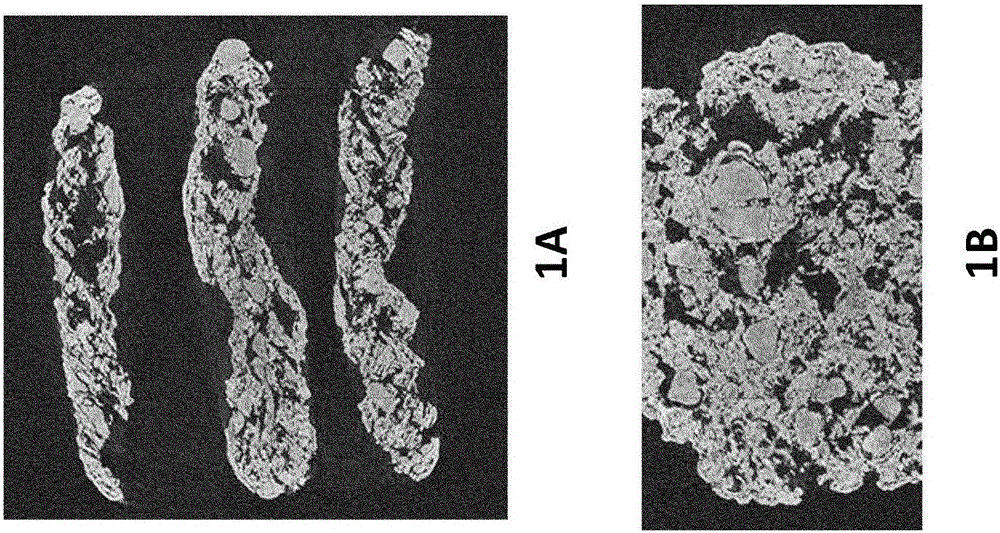

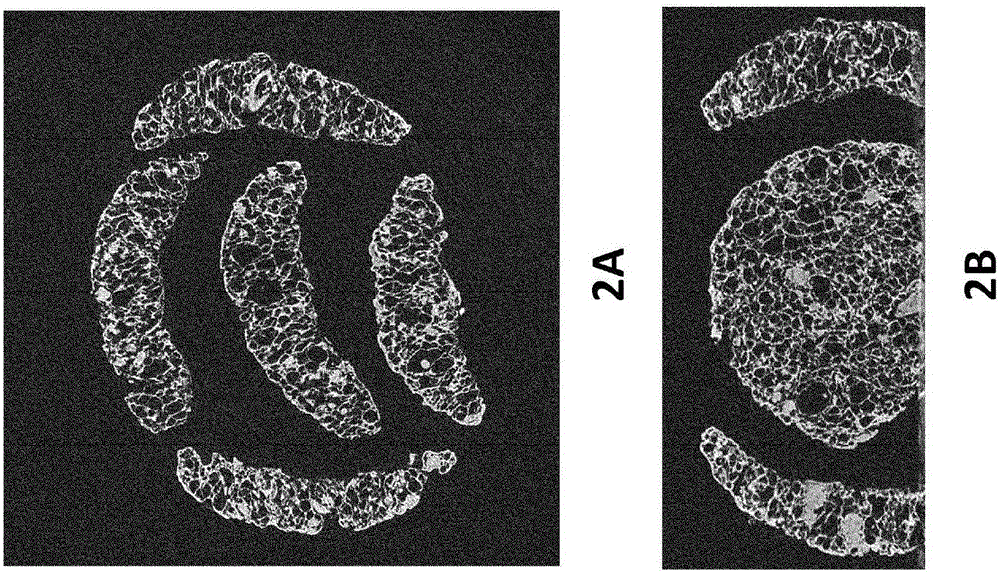

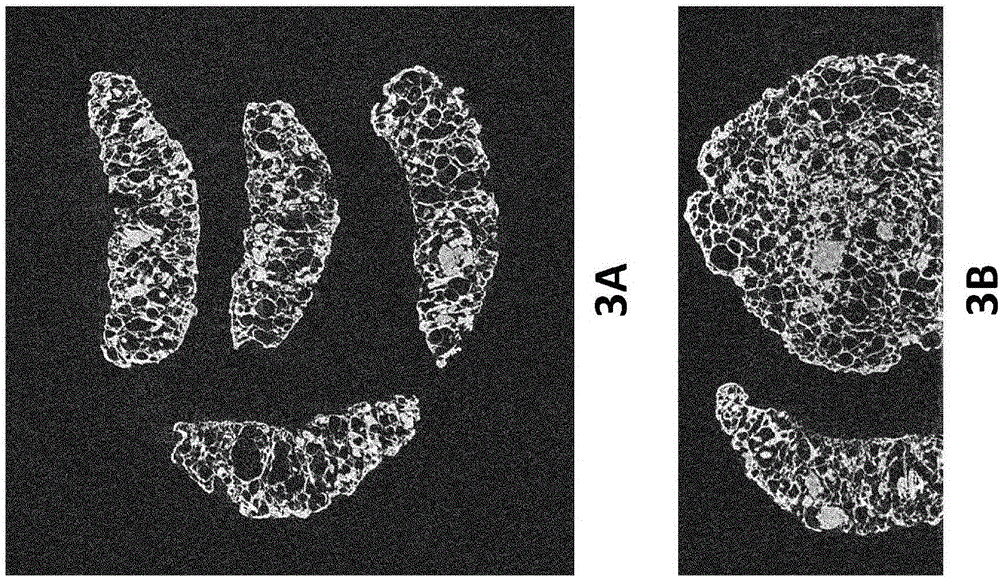

[0081] Cut the extruded product into thin slices. figure 2 , image 3 and Figure 4 Lateral and coronal views of directly extruded slices analyzed for X-ray tomography. Porosity, average wall thickness and liquid absorption were determined following the procedure described in the Methods section. The direct extruded sheet has a porosity of from about 55% to 68% and thin walls with an average wall thickness of 51 μm to 67 μm. Its liquid absorption degree is as high as 360g water / 100g product.

[0082] The porosity of the direct sheet is greater than that of the rolled sheet. The average wall thickness of direct sheet is less than that of rolled sheet. In general, the liquid uptake of the direct sheet was ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average wall thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Average wall thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com