Farmland plastic mulch lifter

A recycling machine and mulching film technology, which is applied in collectors, agricultural machinery and tools, agriculture, etc., can solve the problems of difficulty in meeting the requirements of residual film recycling, low recovery rate of residual film, and high cost, and meet the requirements of residual film recycling operations. The film has low impurity content and good ground profiling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

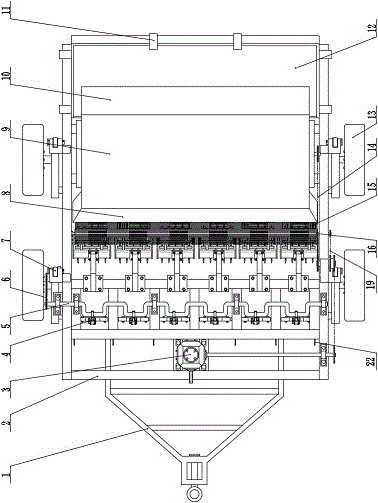

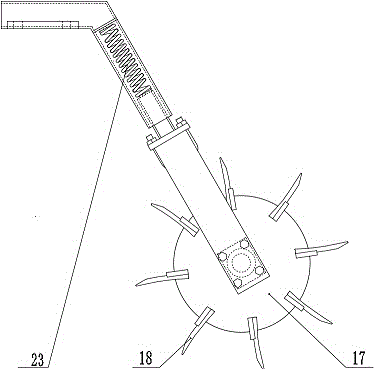

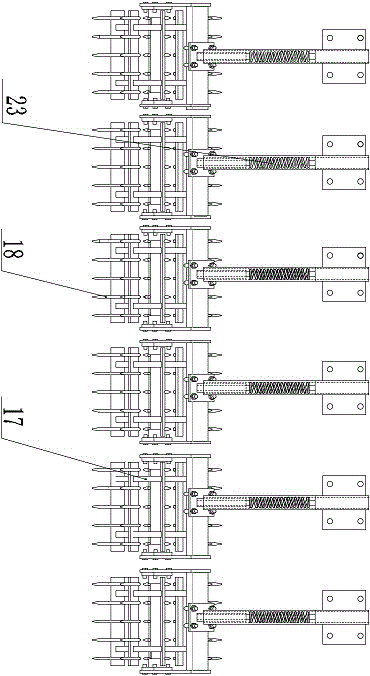

[0018] Embodiment 1: refer to figure 1 , is an embodiment of a farmland plastic film recycling machine, including a traction frame (1), a frame (2), a gearbox (3), a disc cutter (22), a transverse film cutting device, a film picking device, a film stripper device, film collecting device, transverse film cutting device transmission system (6), stripping device transmission system (19), film collecting device transmission system (14), ground wheel (13) and film collecting box (12), characterized in that The traction frame (1) is located on the front side of the frame (2), the gearbox (3) is located on the rear frame (2) of the traction frame (1), and the disc cutter (22) is provided with a spring (23 ), and arranged in rows at the lower part of the beam of the frame (2), the rear side of the gearbox (3), the transverse film cutting device is set at the rear side of the disc cutter (22), and the film picking device is set at the transverse film cutting device On the rear side, t...

Embodiment 2

[0019] Embodiment 2: The difference between this embodiment and Embodiment 1 is that the disc cutter ( 22 ) may be a sawtooth disc film cutting wheel.

Embodiment 3

[0020] Embodiment 3: The difference between the embodiment and the embodiment 1 is that the crankshaft ( 5 ) of the transmission system ( 6 ) of the transverse film cutting device may be a cam mechanism.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com