Numerically-controlled machine tool linear encoder

A technology of linear encoders and CNC machine tools, which is applied to metal processing machinery parts, measuring/indicating equipment, metal processing equipment, etc., can solve problems such as unreasonable encoder settings, deviations, and poor coding effects, and achieve implementation Convenience, reasonable structural design and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] The present invention will be further explained below in conjunction with the accompanying drawings and embodiments.

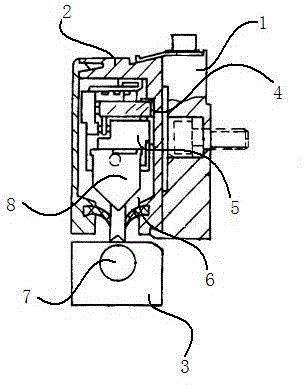

[0010] like figure 1 As shown, a linear encoder for a numerically controlled machine tool includes a mounting base 1, on which a ruler base assembly 2 and a scanning head mounting base 3 are arranged, and the scale base assembly 2 is provided with an installation cavity, and the installation The cavity is provided with a scale grating 4 and a scanning head 5, the scale grating 4 is connected with a scanning head 5, the scanning head 5 is fixed on the scanning head mount 3, and the scanning head 5 is provided with a sealing strip 6, The scanning head mounting base 3 is provided with a through hole, and the through hole is matched with the cable 7 . The scanning head 5 and the sealing strip 6 are connected by a connecting piece 8 .

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap