System and method for preparing dry-mixed mortar

A dry-mixed mortar and silo technology, which is applied in clay preparation devices, chemical instruments and methods, and mixing operation control, etc., can solve the problems of shortening the service life of mixers, increasing the wear and damage of mixing shafts and mixing blades, and the use of small amounts of additives, etc. problems, to achieve the effect of easy handling and maintenance, prolonging service life and shortening mixing time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further described below in conjunction with accompanying drawing, protection scope of the present invention is not limited to the following:

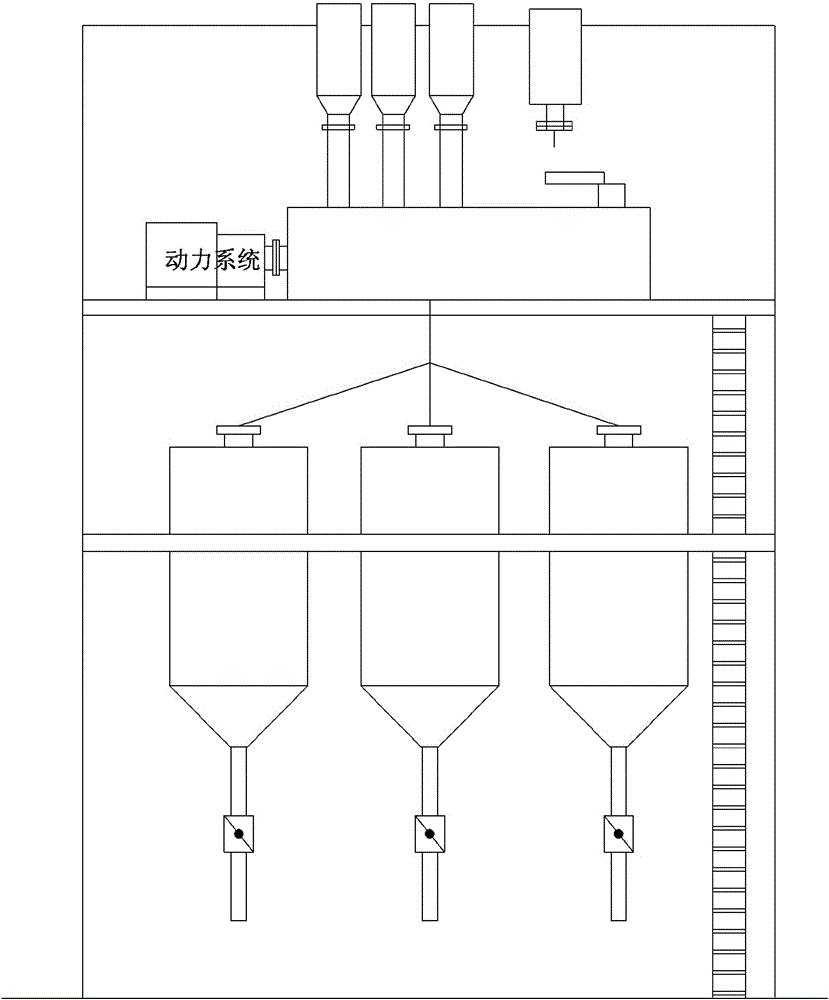

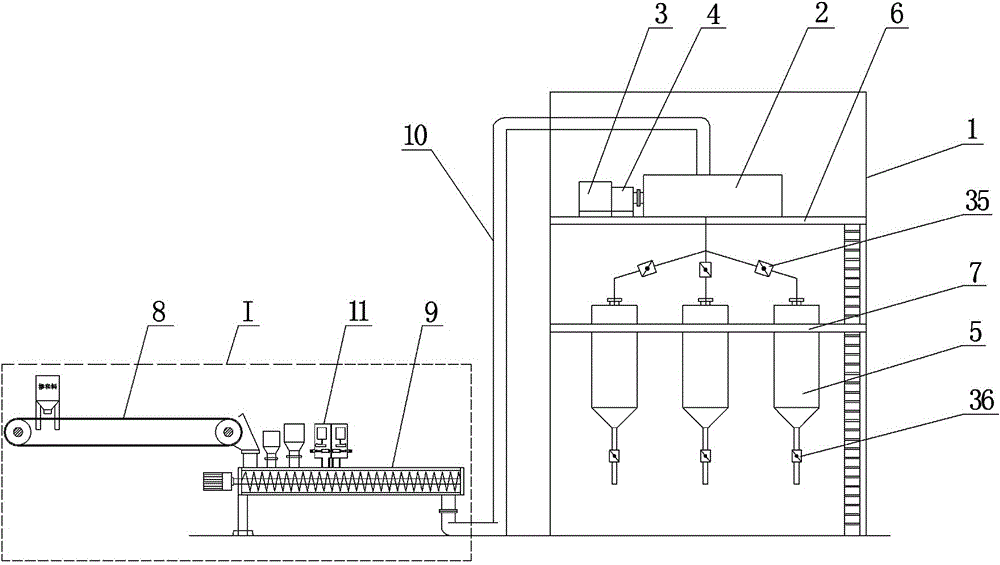

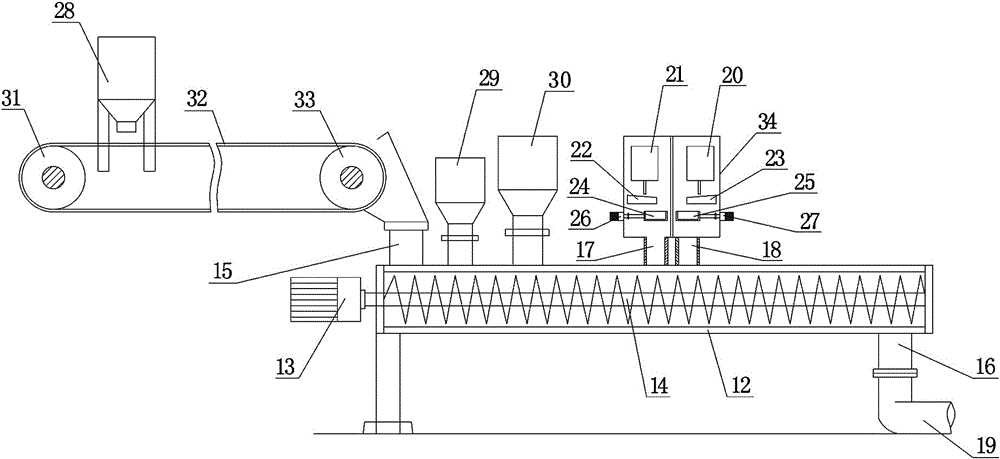

[0033] Such as figure 2 As shown, a system for preparing dry-mixed mortar includes a mixing building 1, a mixer 2, a motor I3, a speed reducer 4, a product silo 5, and an upper partition 6 and a lower partition 7 arranged in the mixing building 1, A ladder is provided in the mixing building 1, and the motor I3, the reducer 4 and the mixer 2 are all fixedly installed on the surface of the upper partition 6, the output end of the motor I3 is connected with the input end of the reducer 4, and the output end of the reducer 4 Connected with the stirring shaft in the mixer 2, the lower partition 7 is provided with a plurality of product bins 5, and a butterfly valve is connected between the upper port of each product bin 5 and the outlet of the mixer 2 through a pipeline I35, the lower port of each produ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com