A kind of preparation method of 3,6-diethoxyfluorane yellow thermosensitive dye

A technology of diethoxyfluoran and heat-sensitive dyes, which is applied in the field of heat-sensitive dyes, can solve the problems of many impurities, difficult discharge, and low yield, and achieve the effects of high purity, avoiding hydrolysis, and high yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

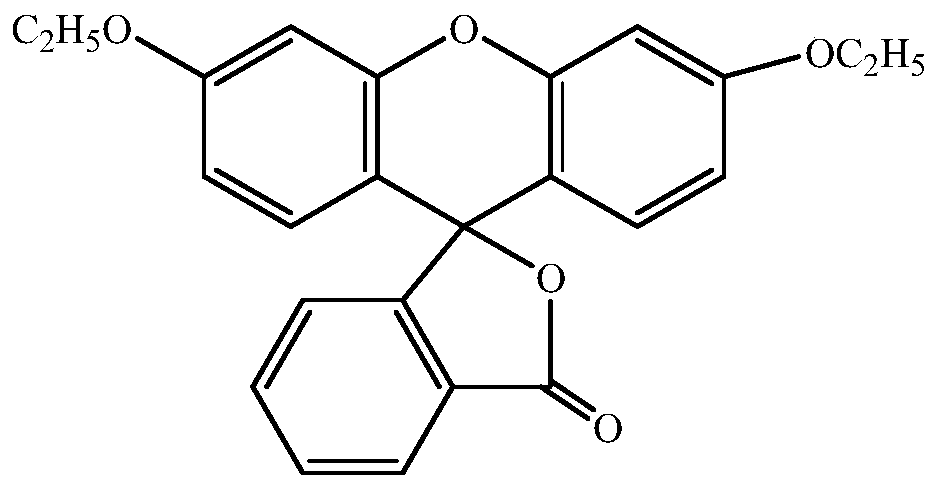

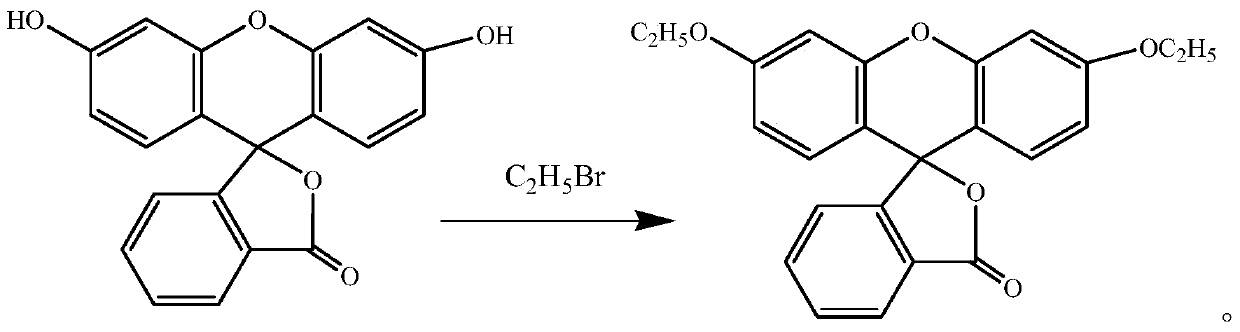

[0023] In a specific embodiment, the preparation method of 3,6-diethoxyfluorane yellow thermosensitive dye of the present invention comprises the following steps: (1) adding fluorescein and a solvent into a reaction vessel, stirring and dissolving at room temperature for 1-2 (2) After adding sodium hydroxide to react for 1 to 2 hours, add sodium carbonate; wherein, the molar ratio between sodium carbonate, sodium hydroxide and fluorescein is 2:2:1~4:2:1; (3) Heat to 40-90°C, add dibromoethane dropwise in 2-4 hours, the molar ratio of dibromoethane to fluorescein is 3:1-5:1, and react at this temperature after the addition is completed 6 to 16 hours; (4) add water to cool down to room temperature, stir and disperse for 8 to 10 hours, filter and dry to obtain the crude product; (5) recrystallize the crude product with a mixed solvent composed of ethyl acetate and dimethyl carbonate , to obtain 3,6-diethoxyfluorane yellow thermosensitive dye. in,

[0024] (1) The reaction formu...

Embodiment 1

[0031] Add 332g of fluorescein and 1000ml of solvent DMF into the reaction flask and stir to dissolve for 1 hour, then add 80g of sodium hydroxide to react for 1 hour, then add 210g of sodium carbonate, heat to 90°C, add 658g of dibromoethane dropwise, dropwise for 2 hours After completion, continue to keep warm at this temperature for 6 hours, add water, cool down to room temperature, stir and disperse for 8 hours, filter, rinse with a large amount of water, and dry to obtain a crude product. Add 351 grams of crude product, 530 ml of ethyl acetate and 530 ml of dimethyl carbonate and heat up to reflux. After all are dissolved, cool and precipitate, filter, and dry to obtain 310.4 g of white 3,6-diethoxyfluorane product with a content of 99.5 wt%. , yield 80%.

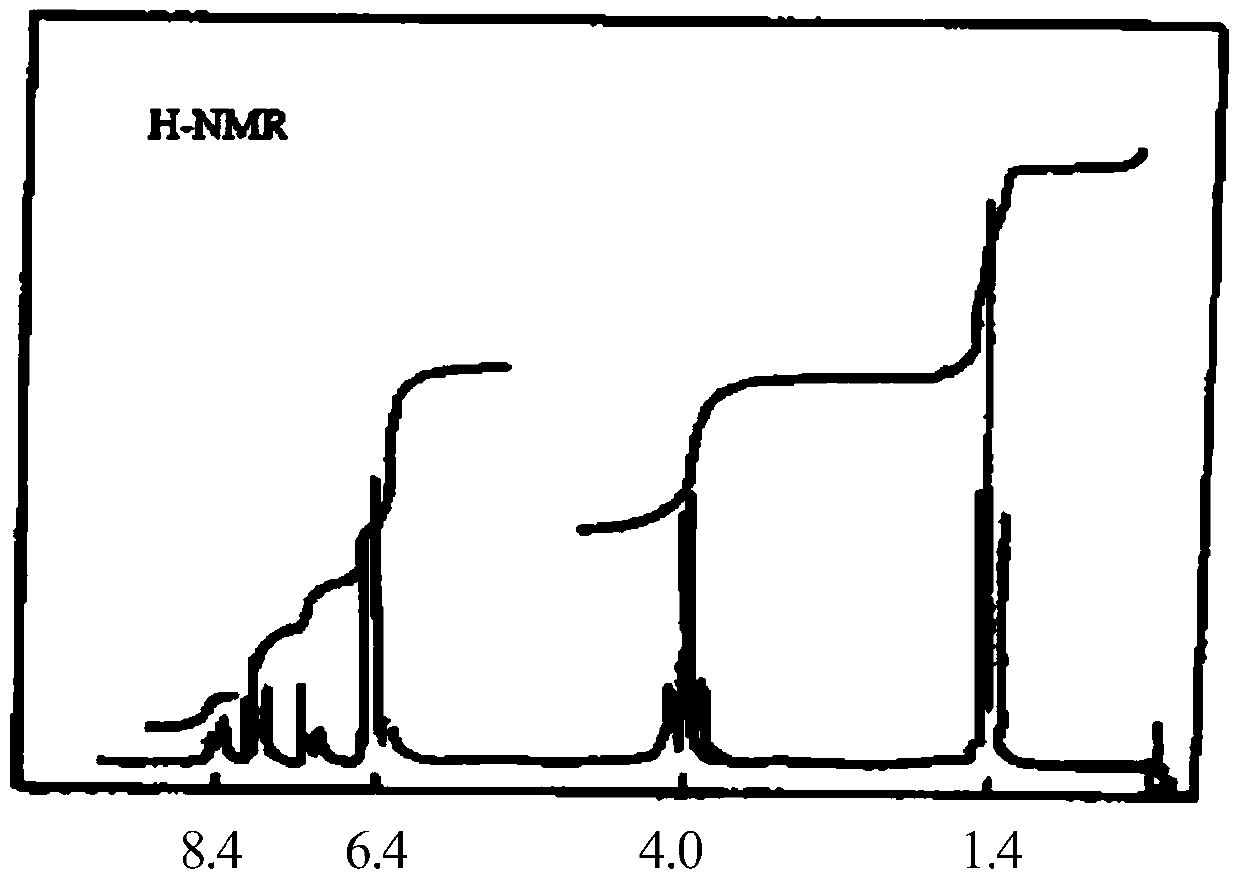

[0032] Such as figure 1 As shown, it can be seen that the NMR data are as follows:

[0033] Table 1: Analysis of 3,6-diethoxyfluorane NMR spectrum

[0034]

[0035] These data illustrate that the product structur...

Embodiment 2

[0037] Add 332g of fluorescein and 1000ml of solvent DMF into the reaction bottle, stir and dissolve for 1 hour, first add 80g of sodium hydroxide and react for 1 hour, then add 263g of sodium carbonate, heat to 80°C, add 658g of dibromoethane dropwise, and add dropwise for 2.5 hours After completion, continue to keep warm at this temperature for 8 hours, add water, cool down to room temperature, stir and disperse for 8.5 hours, filter, rinse with a large amount of water, and dry to obtain a crude product. Add 350 grams of crude product, 465 ml of ethyl acetate and 930 ml of dimethyl carbonate and heat up to reflux. After all are dissolved, cool and precipitate, filter and dry to obtain 309.6 g of white 3,6-diethoxyfluorane product with a content of 99.4 wt%. , yield 79.8%.

[0038] Such as figure 1 As shown, it can be seen that the NMR data are as follows:

[0039] Table 2: Analysis of 3,6-diethoxyfluorane NMR spectrum

[0040]

[0041] These data illustrate that the pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com