A device for preheating raw materials for sintering by using steam and sludge

A technology for sludge and raw materials, applied in the field of sintering ore, can solve the problems of low temperature of sintering mixture, increase of sintered wet layer, limited temperature increase, etc., and achieve the effect of increasing material temperature, improving utilization coefficient and small site demand

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

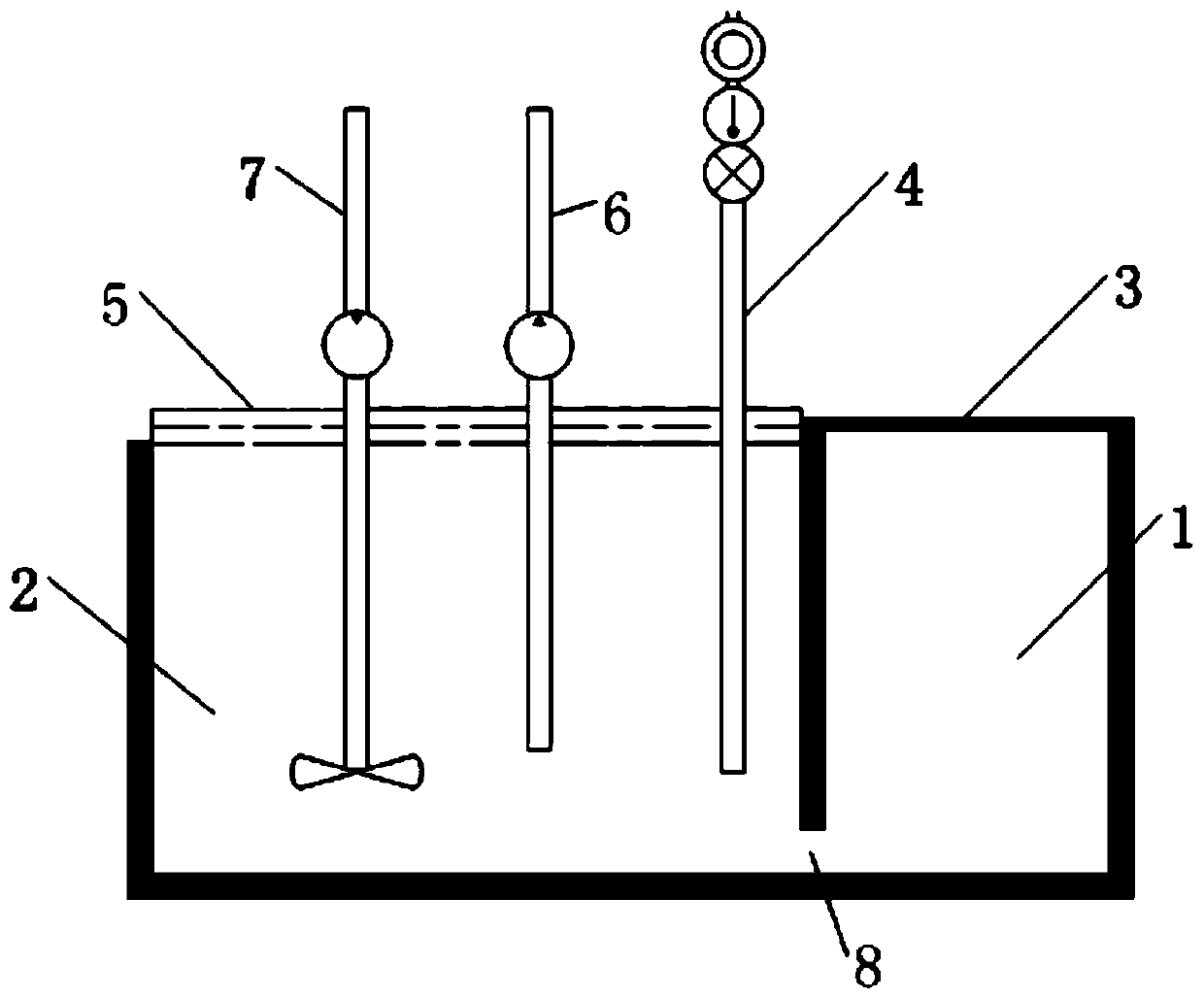

[0026] The present invention includes a primary concentration pool 1, a secondary concentration pool 2, a filter screen 3, a steam pipeline 4, a lifting platform 5, a sludge pump 6, a mud stirring paddle 7, a through hole 8 and supporting steelmaking primary sedimentation tanks, spiral Conveyor, inclined plate sedimentation tank. The primary concentration pool 1 and the secondary concentration pool 2 communicate with the primary concentration pool 1 through the bottom through hole 8, the filter screen 3 is located on the upper part of the primary concentration pool 1, and the steam pipeline 4 is located at the four corners of the secondary concentration pool 2. The platform 5 is located above the secondary thickening tank 2, and the sludge pump 6 and the supporting mud stirring paddle 7 are installed in the middle of the lifting platform 5.

[0027] Among them, the primary thickening tank 1 and the secondary thickening tank 2 are used to settle concentrated sludge. The filter...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com