Vacuum smelting process for nickel-based alloy containing aluminium, titanium, boron and zirconium

A nickel-based alloy, vacuum smelting technology, applied in the field of alloy smelting technology, can solve the problems of easy segregation, affecting the overall performance of the alloy, low density, etc., and achieve the reduction of harmful gas and low-melting impurity content, and the alloy melt is pure and improved. The effect of long-lasting performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

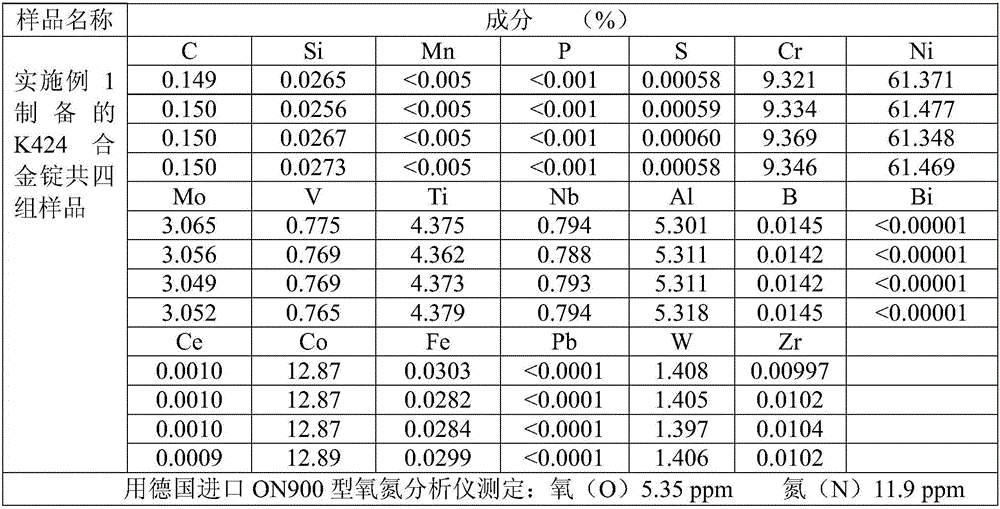

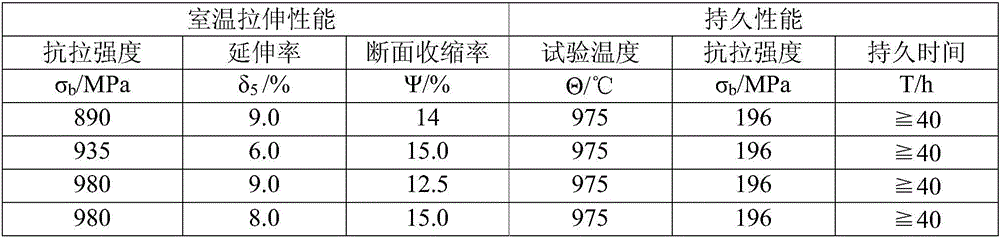

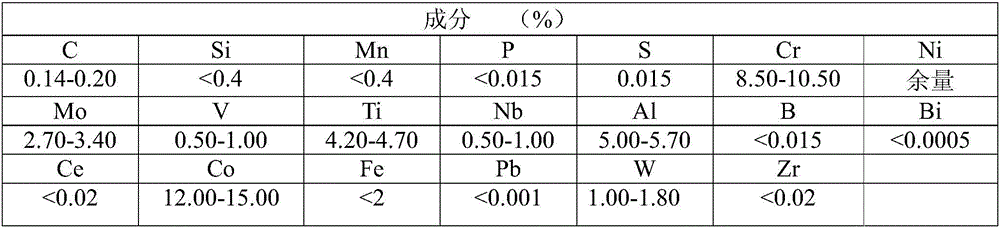

[0023] Taking the K424 alloy as an example, the vacuum smelting process of the present invention is used to produce the K424 alloy ingot, its chemical composition is shown in Table 1, its performance parameters are shown in Table 2, the K424 alloy standard chemical composition is shown in Table 3, and the K424 alloy standard performance parameters are shown in Table 4.

[0024] Using a 200Kg vacuum furnace, the smelting process is as follows:

[0025] (1) Add all elements in the nickel-based alloy except aluminum, titanium, boron, zirconium and nickel to the crucible of the vacuum furnace and smelt at 1570±10°C for 20 minutes;

[0026] (2) Cool down to 1380±10°C, add aluminum and titanium to it, heat up until the aluminum and titanium are completely melted, and then stir for 3 minutes;

[0027] (3) Keep the temperature at 1420±10°C, add nickel-boron alloy and zirconium to it, heat up at 200KW until the nickel-boron alloy and zirconium are completely melted, and then stir for 5...

Embodiment 2

[0040] The smelting process is as follows:

[0041] (1) Add all elements in the nickel-based alloy except aluminum, titanium, boron, zirconium and nickel to the crucible of the vacuum furnace and smelt at 1580±10°C for 25 minutes;

[0042] (2) Cool down to 1370±10°C, add aluminum and titanium to it, heat up until the aluminum and titanium are all melted, and then stir for 4 minutes;

[0043] (3) Keep the temperature at 1430±10°C, add nickel-boron alloy and zirconium to it, heat up at 200KW until the nickel-boron alloy and zirconium are completely melted, and then stir for 4 minutes to obtain a molten metal;

[0044] (4) Cool down, freeze the molten metal, when the temperature drops to 1360±10°C, then raise the temperature to 1470±10°C with 200KW, reduce the power to 80KW, and carry out tapping and pouring.

[0045] All the other are as embodiment 1.

Embodiment 3

[0047] The smelting process is as follows:

[0048] (1) Add all elements in the nickel-based alloy except aluminum, titanium, boron, zirconium and nickel to the vacuum furnace crucible and smelt at 1560±10°C for 30 minutes to form a molten metal;

[0049] (2) Cool down to 1390±10°C, add aluminum and titanium to it, heat up until the aluminum and titanium are all melted, and then stir for 5 minutes;

[0050] (3) Keep the temperature at 1410±10°C, add nickel-boron alloy and zirconium to it, heat up at 200KW until the nickel-boron alloy and zirconium are completely melted, and then stir for 3 minutes to obtain a molten metal;

[0051] (4) Cool down and freeze the molten metal. When the temperature drops to 1380±10°C, heat up to 1450±10°C with 200KW and reduce the power to 80KW for tapping and pouring.

[0052] All the other are as embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com