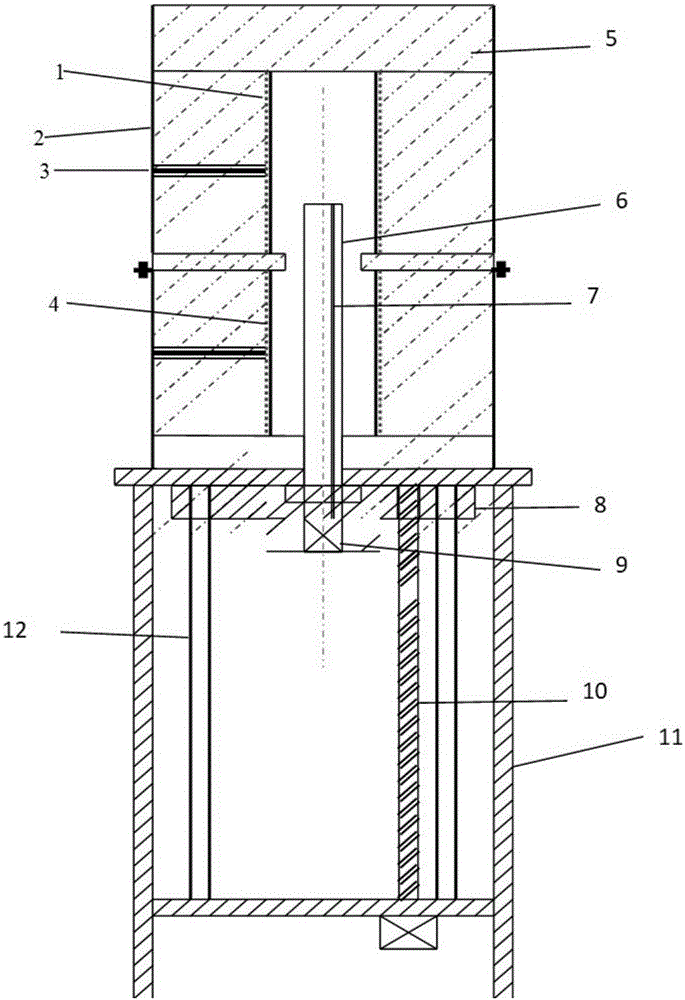

Crystal growing device

A technology of crystal growth and lifting device, applied in the direction of crystal growth, single crystal growth, single crystal growth, etc., can solve crystal defects, reduce crystal crystallization temperature and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0055] 1) BaCO with a purity of 99.99% is used 3 with NH 4 h 2 PO 4 as raw material. Among them, BaCO 3 with NH 4 h 2 PO 4 The molar ratio is 5:6. BaCO 3 with NH 4 h 2 PO 4 Mix and place in a mortar and grind thoroughly for 30 minutes before tableting. The raw material blocks after tableting are placed in a corundum crucible and sintered at 750°C for 24 hours in an open environment to remove CO 2 , NH 3 with H 2 O, polycrystalline starting materials were synthesized.

[0056] 2) then the polycrystalline raw material obtained in step 1) and BaCl 2 , CsCl according to the stoichiometric ratio of 1:1:1 mixed uniformly, and ground to obtain a uniform mixture of raw materials.

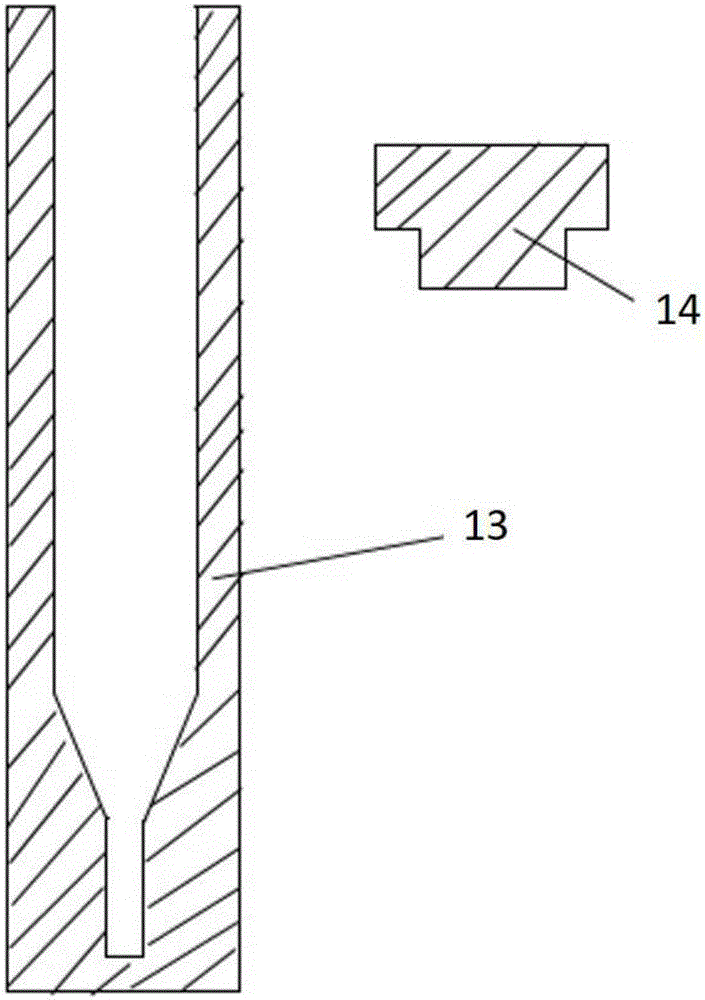

[0057] 3) Put the homogeneous raw material mixture in figure 2 in a covered graphite crucible as shown in . Then sealed in a vacuum of 10 -4 in the quartz tube. Fix the sealed quartz tube on the crucible support rod, raise the crucible support rod to make the quartz tube fixed by the cr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com