Suspension type monorail transportation concrete structure suspension system

A concrete structure and monorail transportation technology, applied in the direction of tracks, bridge parts, roads, etc., can solve the problems of small vehicle load, unfavorable track beam alignment control, prone to force buckling, etc., to achieve increased capacity and seismic capacity, effective Conducive to the control of linearity and the effect of preventing buckling under force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described with reference to examples.

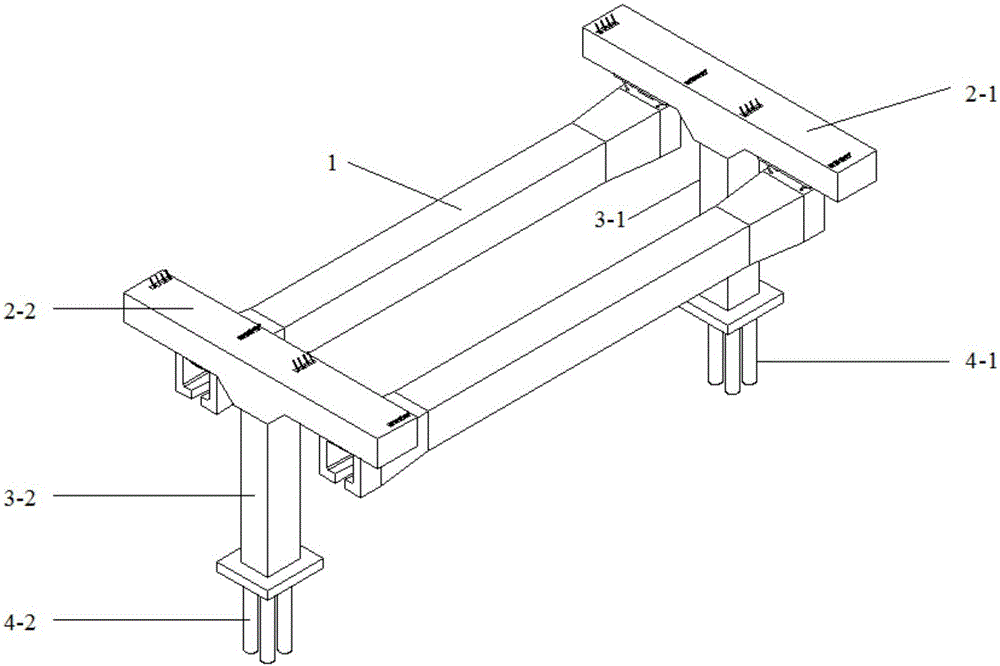

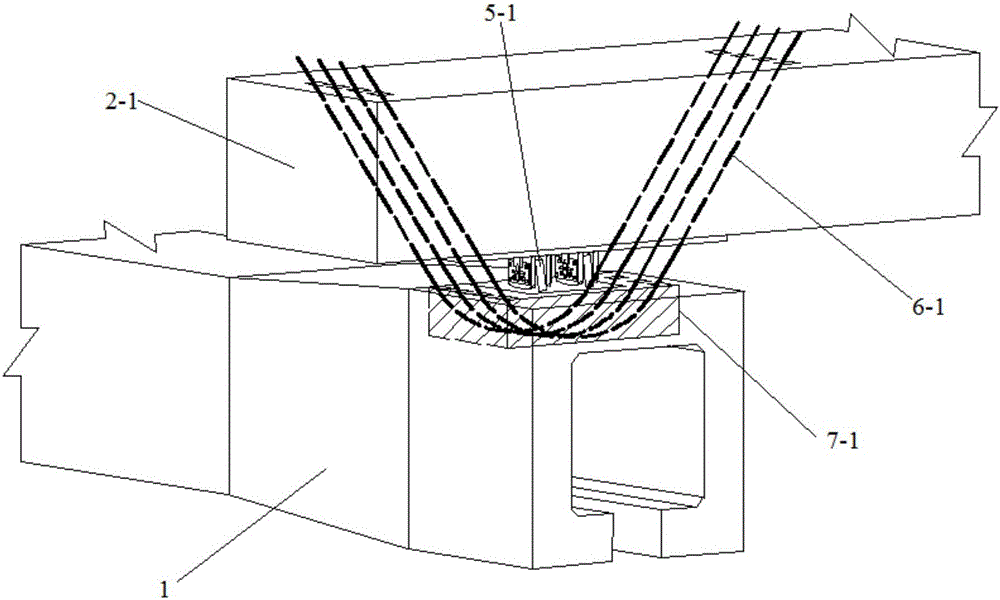

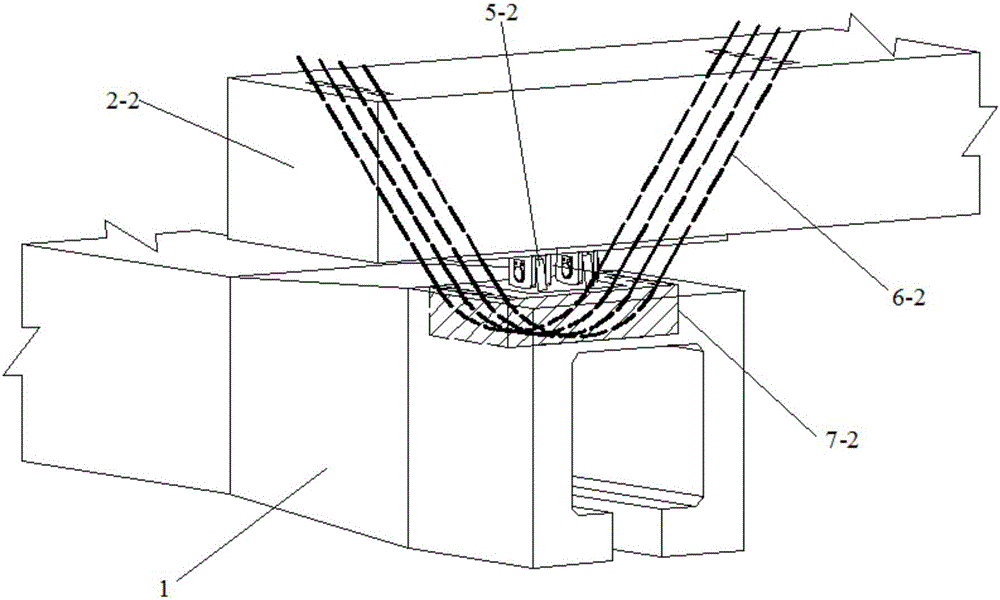

[0015] Example A suspension system of a suspended monorail traffic concrete structure uses concrete track beam 1, pier cover beam 2-1, pier cover beam 2-2, concrete pier column 3-1, concrete pier column 3-2, and bridge pier foundation 4- 1. Bridge pier foundation 4-2, movable support 5-1, fixed support 5-2, cable 6-1, cable 6-2, base 7-1, base 7-2.

[0016] Step 1 In the beam-making stage of the workshop, the reinforcement cage of the concrete track beam 1 is bound, and the base 7-1 and the base 7-2 are placed at the design positions of the two ends of the roof reinforcement cage, and the concrete track beam 1 is poured.

[0017] Step 2 Complete the fabrication of the pier structure on site, including pier cover beam 2-1, pier cover beam 2-2, concrete pier column 3-1, concrete pier column 3-2, pier foundation 4-1, pier foundation 4-2 ,like figure 1 shown.

[0018] Step 3 In the beam erectio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com