A method for quickly strengthening reinforced concrete eccentric columns

A reinforced concrete and concrete surface technology, which is applied in construction, building maintenance, building construction, etc., can solve the problems of limited improvement of column ductility due to outsourcing angle steel reinforcement, can not be put into use quickly, and has a great impact on the structure's own weight, so as to increase the overall Reliable performance of performance and bonding, fewer reinforcing components, and shortened construction period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

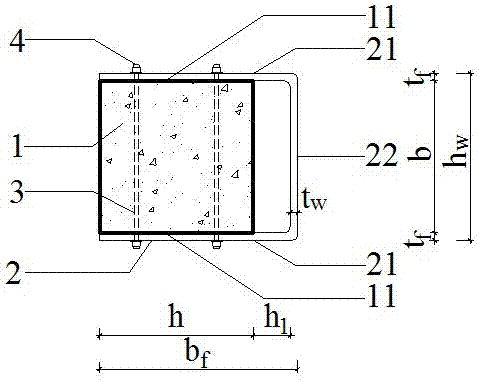

[0028] A method for quickly reinforcing a reinforced concrete eccentric column, comprising the following steps:

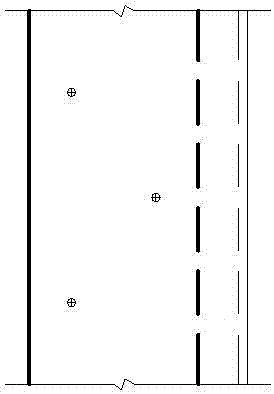

[0029] Step 1, making channel steel 2 for reinforcement matching the cross-sectional size of bias column 1, and reserving bolt holes on flanges 21 on both sides of channel steel 2;

[0030] Step 2, the two opposite concrete surfaces in the height direction of the cross-section of the bias column 1 are bonded anchorage areas 11, and the bonded anchorage areas 11 of the bias column 1 are polished and smoothed;

[0031] Step 3, install the channel steel 2 to the designed position, and drill bolts on the surface of the bonded anchorage area 11 of the bias column 1 according to the positions of the bolt holes reserved on the flanges 21 on both sides of the channel steel 2 Holes, and cleaning and reaming of holes;

[0032] Step 4, apply building structural glue on the bonded anchorage area 11 of the bias column 1, and put the channel steel 2 on it;

[0033] Step 5, inj...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com