High-energy friction brake

A friction brake, high-energy technology, applied in the field of vehicle engineering, can solve the problem of no drum brake braking effect and other problems, and achieve the effects of improving performance stability, simple structure and good reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

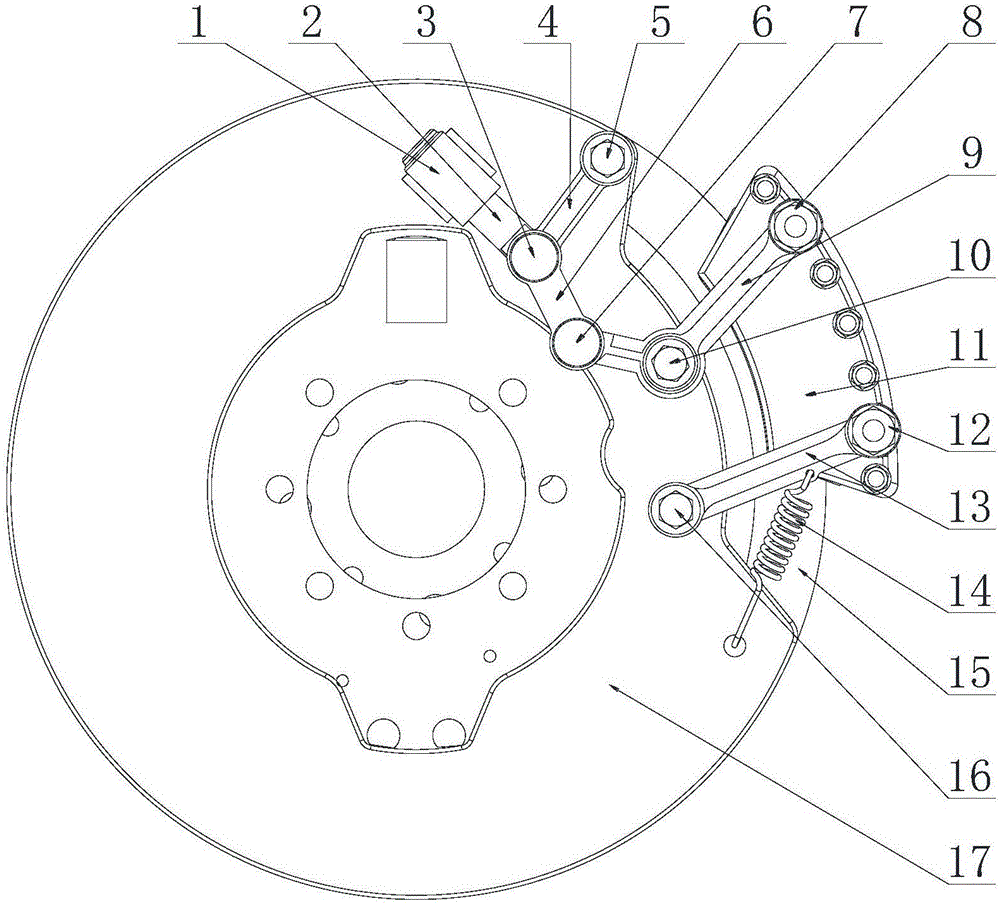

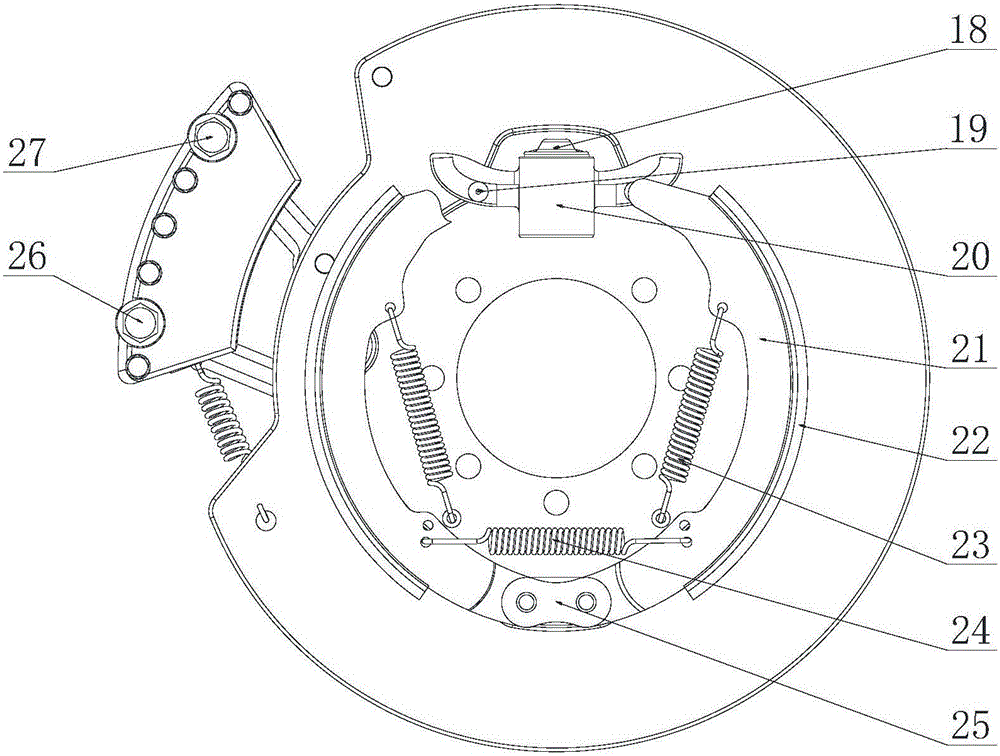

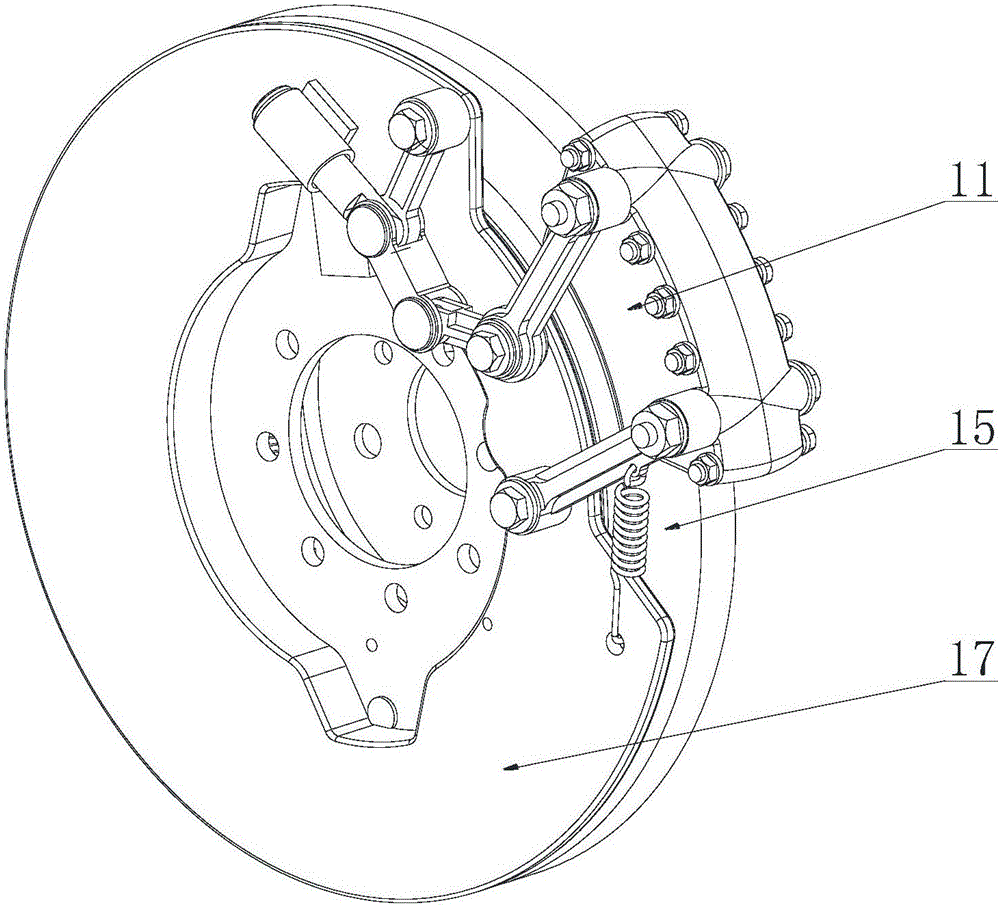

[0024] combined with Figure 1-11 , to further describe the present invention.

[0025] The invention provides a high-energy friction brake using a disc brake structure and a drum brake structure in parallel, comprising a disc brake master cylinder 1, a disc brake active push rod 2, a disc brake active push rod cylinder Pin 3, upper connecting rod 4, upper connecting rod retaining bolt 5, lower connecting rod 6, active arm cylindrical pin 7, active arm connecting bolt 8, active arm 9, active arm retaining bolt 10, brake caliper 11, slave Boom connecting bolt 12, driven arm 13, disc brake return spring 14, brake disc 15, driven arm locking bolt 16, brake bottom plate 17, drum brake master cylinder 18, drum brake Roller 19, drum brake cam 20, brake shoe 21, drum brake friction plate 22, drum brake longitudinal return spring 23, drum brake lateral return spring 24, brake shoe support pin cover 25, slave arm connecting nut 26, active arm connecting nut 27 form.

[0026] The afo...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap