An Ultrasonic Residual Stress Test Method That Can Correct the Effect of Grain Size Difference

A technology of residual stress and testing method, which is applied in the direction of force/torque/work measuring instrument calibration/testing, force/torque/work measuring instrument, measuring force, etc. Development of Residual Stress Test Method and Other Issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

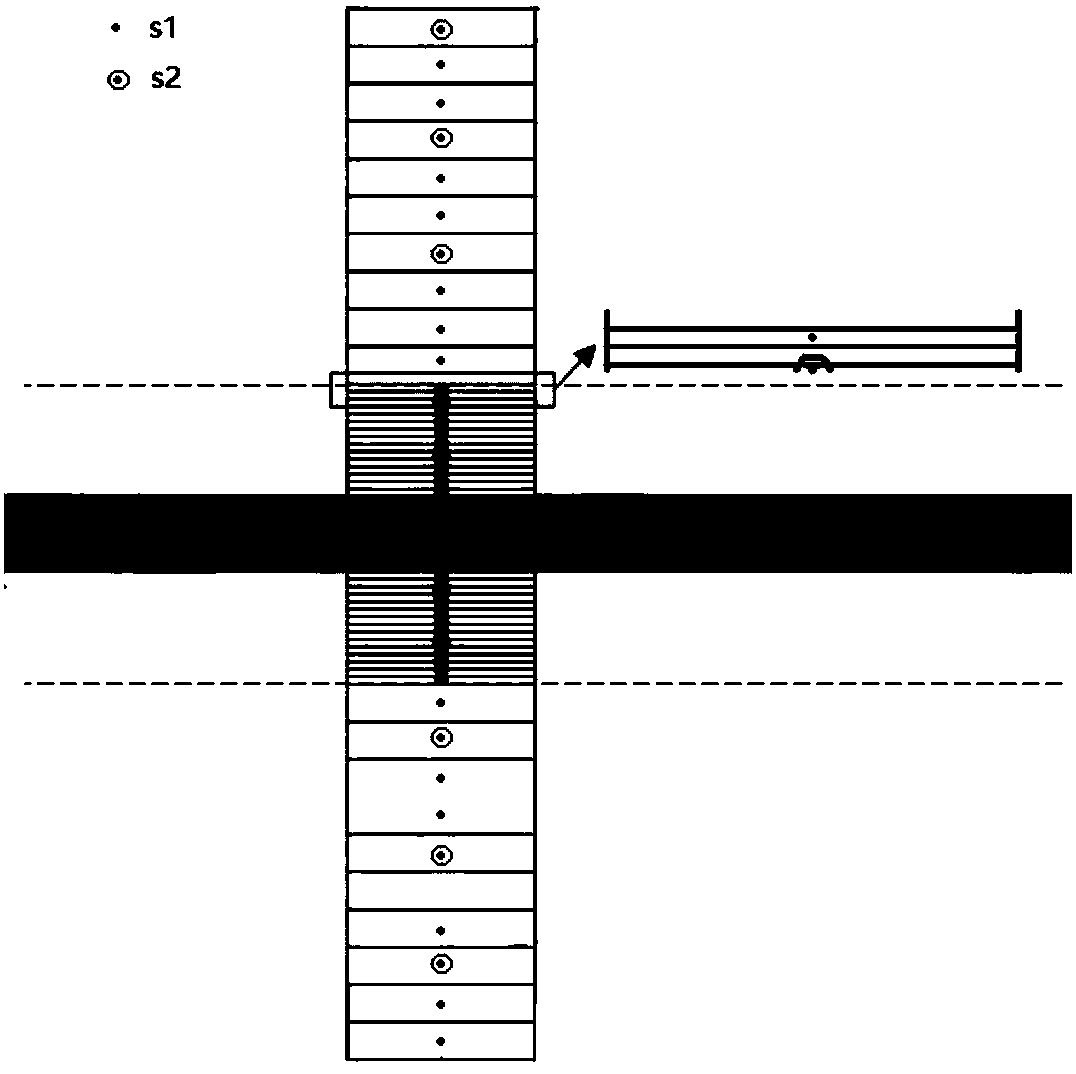

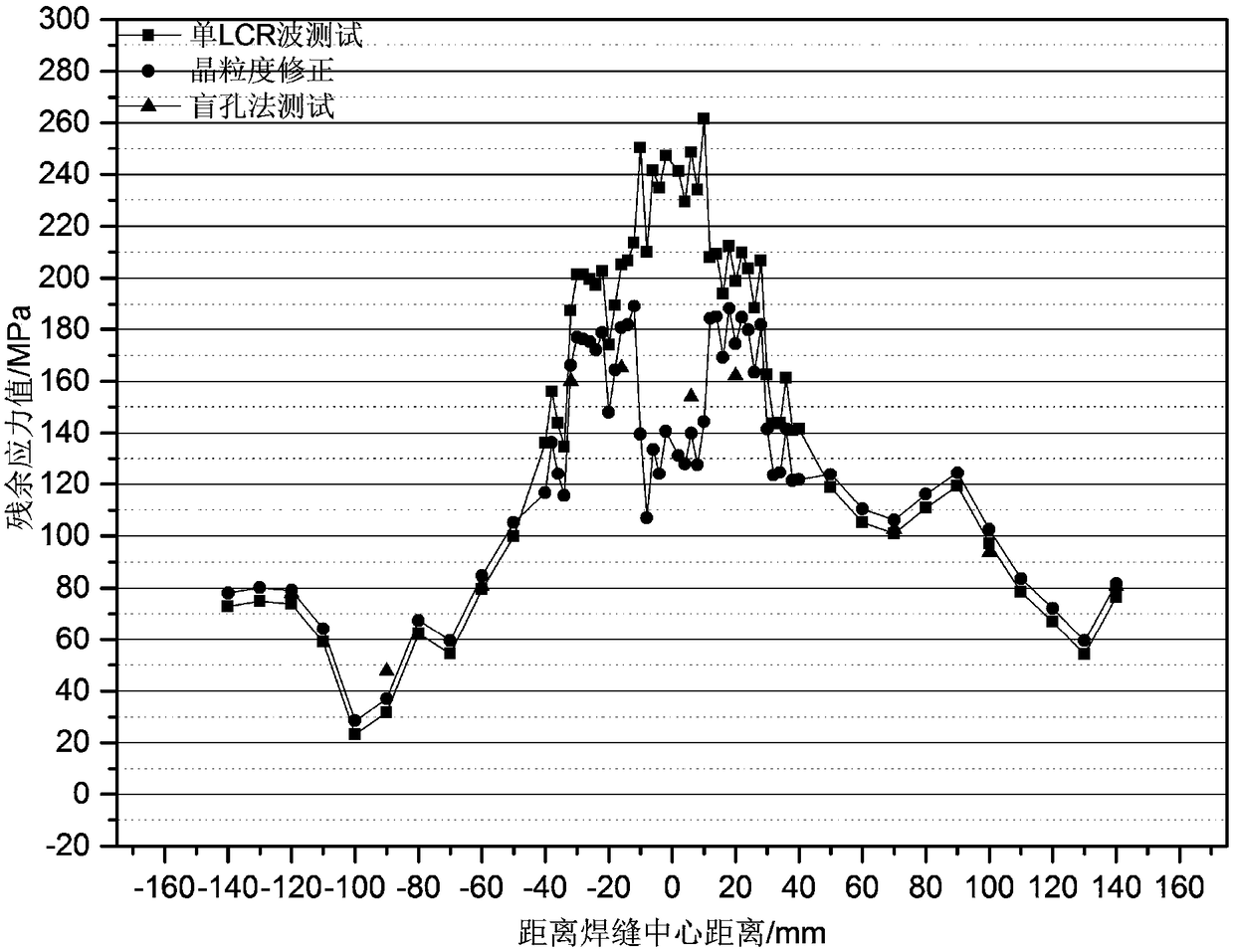

[0050] A specific embodiment of the present invention is: an ultrasonic residual stress testing method capable of correcting the influence of grain size differences, the steps of which are as follows:

[0051] A. Prepare grain size test sample

[0052] A1. Cut n groups of tensile samples parallel to the rolling or extrusion direction of the material, denoted as N 1 Group, N 2 group...N n-1 Group, N n group, each group of stretched samples includes the same stretched sample r a root;

[0053] A2. Do not do any treatment on the stretched samples of group N1, and 2 -N n Groups of stretched samples are subjected to heat treatment under different conditions, and the heat treatment conditions of the same group of stretched samples are the same, and the specific heat treatment conditions are: N 2 group tensile sample at temperature T a ℃ heat preservation h a hours, N 3 group tensile sample at temperature Ta ℃ heat preservation h a +Δh a hours...N n-1 group tensile sampl...

Embodiment 2

[0077] The ultrasonic residual stress testing method of the present embodiment is basically the same as that of the first embodiment, except that the selection of parameters in the steps is different, and the selection of each step parameter in the present embodiment is as follows:

[0078] In the step A1 described in this example, n groups of tensile samples are cut parallel to the rolling or extrusion direction of the material, and the group number n is 5. In the step A1, n groups of stretched samples are cut parallel to the rolling or extrusion direction of the material, and the number of stretched samples included in each set of stretched samples is r a for 4. For N in the step A2 2 -N n Group stretched samples were subjected to heat treatment under different conditions, N 2 group tensile sample at temperature T a ℃ heat preservation h a Holding temperature T in hours a °C is the grain growth temperature of the tested tensile sample material. For N in the step A2 2...

Embodiment 3

[0080] The ultrasonic residual stress testing method of the present embodiment is basically the same as that of the first embodiment, except that the selection of parameters in the steps is different, and the selection of each step parameter in the present embodiment is as follows:

[0081] In the step A1 described in this example, n groups of tensile samples are cut parallel to the rolling or extrusion direction of the material, and the group number n is 4. In the step A1, n groups of stretched samples are cut parallel to the rolling or extrusion direction of the material, and the number of stretched samples included in each set of stretched samples is r a for 3. For N in the step A2 2 -N n Group stretched samples were subjected to heat treatment under different conditions, N 2 group tensile sample at temperature T a ℃ heat preservation h a Holding temperature T in hours a °C is the grain growth temperature of the tested tensile sample material. For N in the step A2 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com