Double-platform shunt-excitation horizontal vibration test system with combined table facet

A vibration test and horizontal technology, which is applied in vibration test, machine/structural component test, measuring device, etc. It can solve the problems that the deformation is not easy to control, and can not be split into a single unit for use, so as to save test cost and frequency The effect of good transfer characteristics and strong matching

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The double-stage parallel-excited horizontal vibration test system of the present invention will be further described below in conjunction with the accompanying drawings. This description is only exemplary and is not intended to limit the protection scope of the present invention.

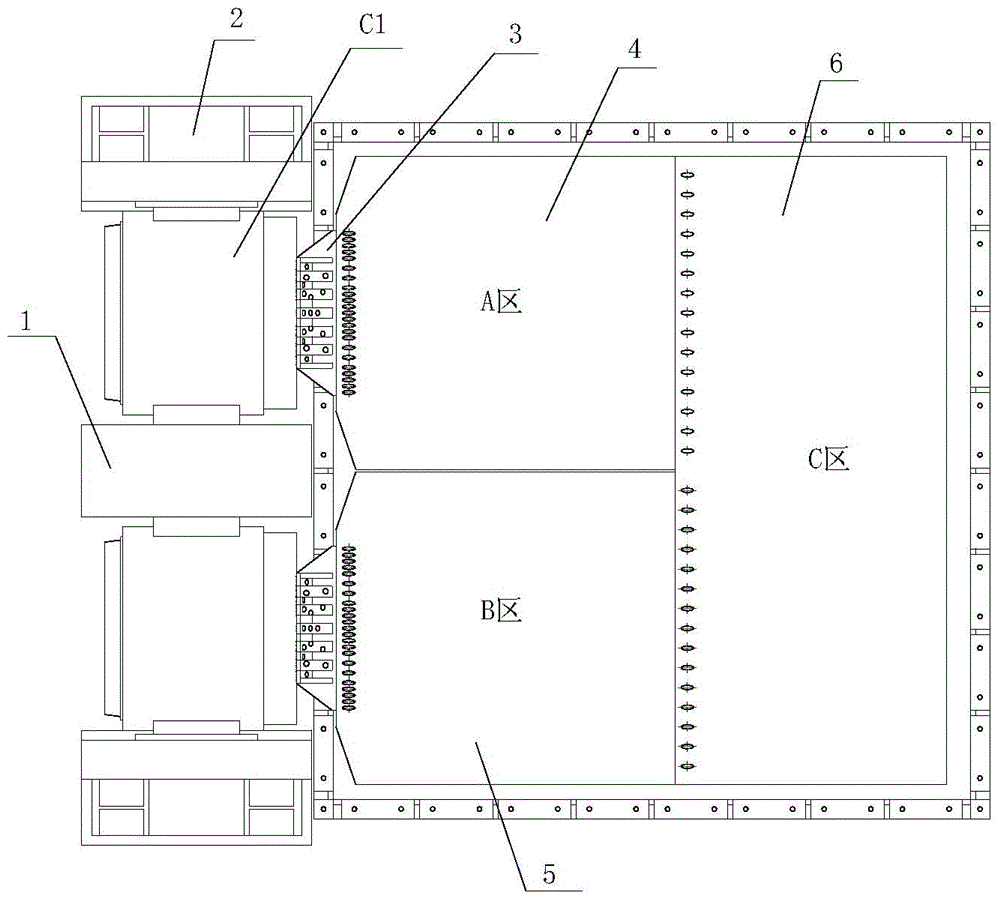

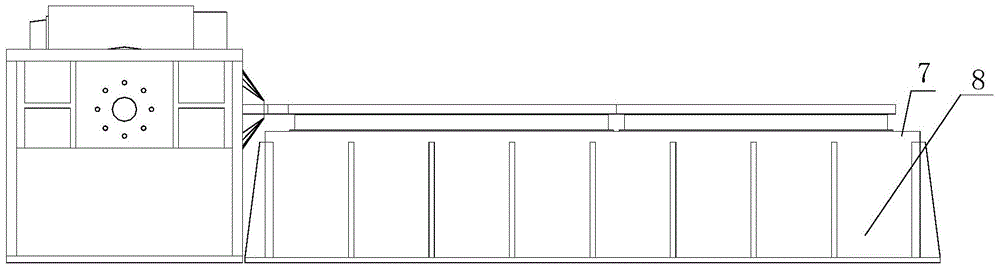

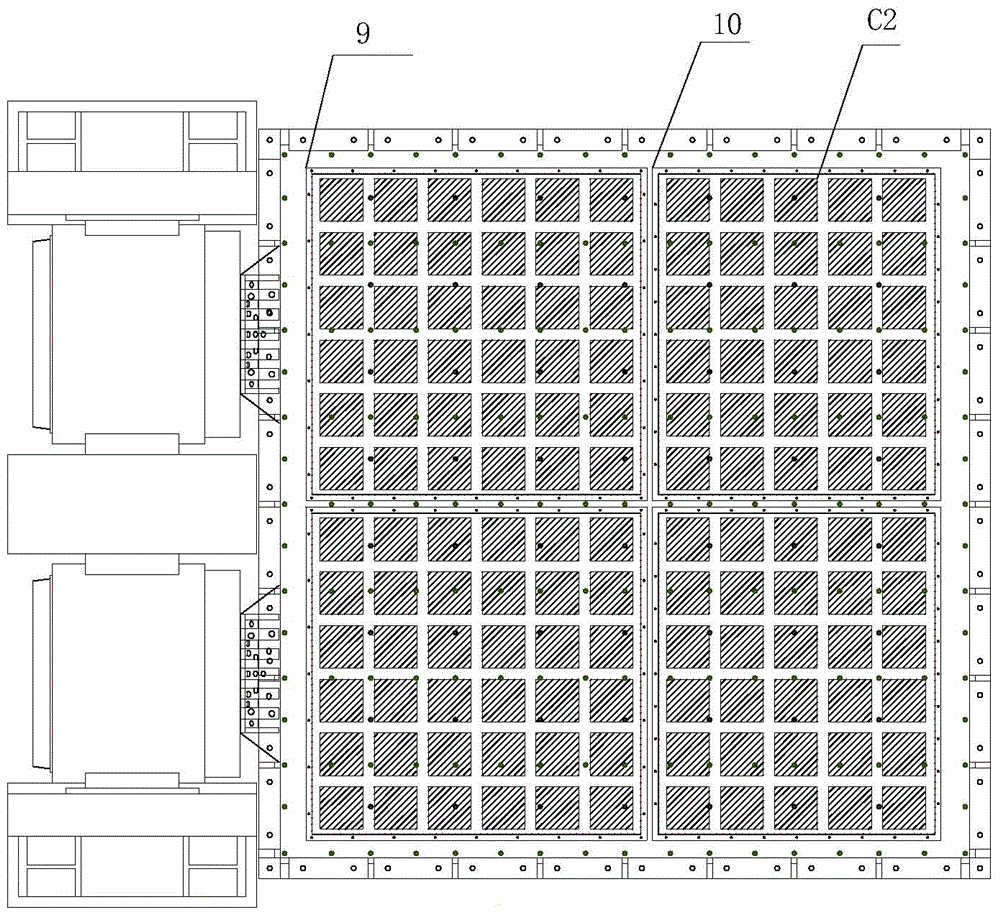

[0026] figure 1 Shown is the top view of the dual-stage parallel excitation horizontal vibration test system of the present invention. figure 2 It is the front view of the double-stage parallel excitation horizontal vibration test system of the present invention. The dual-stage parallel excitation horizontal vibration test system of the present invention comprises two vibrating table bodies C1, two outer support bases 1, one inner support base 2, two connectors 3 (i.e. bull head connectors), a horizontal slide base Seat 8, bearing mounting plate 7, bearing C2, oil tank frame 9, horizontal slide plate A, and horizontal slide plate B, wherein, the inner support base 2 is set in the middle of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com