Cotton fiber maturity measuring method based on densitometry

A measurement method, cotton fiber technology, applied in the textile field, can solve problems such as high labor intensity, wasteful use of instruments, and large subjective influence on test results, and achieve the effects of high degree of automation, simple operation, and convenient measurement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

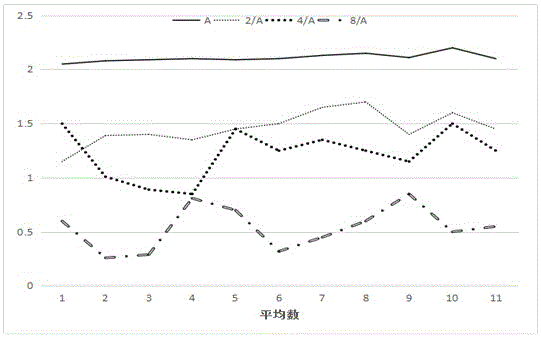

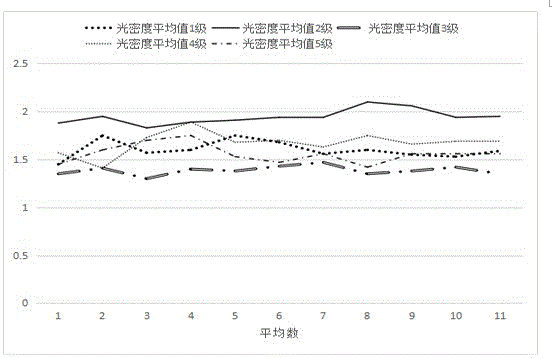

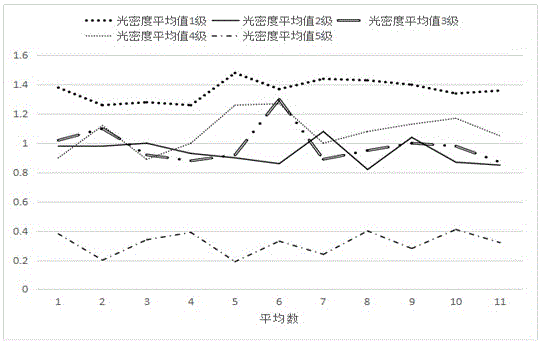

[0009] A method for measuring the maturity of cotton fibers based on the coloring method of the present invention uses the optical density of cotton fibers to test the maturity of cotton fibers after dyeing with iodine. When the maturity of cotton fibers is high, the more cellulose content, the higher the concentration of iodine blue reaction products. The greater the measured optical density; the concentration of liquid A is divided into four grades, namely A, A / 2, A / 4, A / 8, and the best A solution concentration of A / 4 tests the average optical density of cotton fibers, which can be clearly judged Cotton fibers are overripe, mature or immature.

[0010] The cotton fiber is colored with iodine, cut off a bundle of fibers about 0.3 mm with a Hastelloy slicer, place it on a grooved glass slide, crush the fiber with a glass rod, add 1-2 drops of nail solution and stir fully, Add liquid B dropwise and stir thoroughly to make a sample.

[0011] The iodine blue reaction is positive...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com