Novel cable assembly transient fault detection device and method

A fault detection and cable assembly technology, which is applied in the field of new cable assembly transient fault detection devices, can solve the problems of inability to realize three-dimensional, flat cable fixation, single function, unable to meet the design and manufacturing trends of three-dimensional and flat cables, etc. Achieve the effect of improving the ability of cable fault screening

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

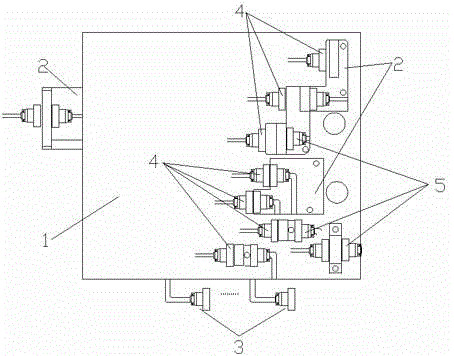

[0033] Such as figure 1 As shown, the present invention provides a novel cable assembly transient fault detection device, including:

[0034] Vibration device universal base 1;

[0035] A plurality of mounting brackets 2 fixed on the general base of the vibration device, specifically, each mounting bracket is set correspondingly according to the specific structure of the cable assembly to be tested;

[0036] A plurality of signal transmission process cables 5, each signal transmission process cable is provided with electrical connectors at both ends respectively, the electrical connector at the first end of each signal transmission process cable is fixed on a mounting bracket, each cable to be tested The electrical connector of component 4 is connected with the electrical connector of the first end of the signal transmission process cable on a mounting bracket;

[0037] Signal output process cables 3 having the same number as the signal transmission process cables, electrica...

Embodiment 2

[0056] The present invention provides a novel cable assembly transient fault detection method, including:

[0057] Step S1, fixing multiple mounting brackets on the common base of the vibration device;

[0058] Step S2, fixing the electrical connector at the first end of each signal transmission process cable on a mounting bracket, and connecting the electrical connector of each cable assembly to be tested with the first end of the signal transmission process cable on a mounting bracket electrical connector connection;

[0059] Step S3, connecting the electrical connector at the first end of each signal output process cable to the electrical connector at the second end of a signal transmission process cable;

[0060] Step S4, connecting the plurality of connectors provided by the transient-on and transient-off fault detection equipment to the electrical connectors at the second end of each signal output process cable;

[0061] In step S5, the transient on-off fault detection...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com