Method for improving strength of ruggedized computer plastic structural member and plastic structural member

A technology for strengthening computers and structural parts. It is used in computing, digital data processing parts, instruments, etc. It can solve problems such as poor strength, and achieve the effects of convenient use, light weight and improved strength.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] A method for increasing and strengthening the strength of computer plastic structural parts of the present invention comprises the following steps:

[0033] (1) By opening a groove on the surface of the non-mold plastic structural part with a thinner wall thickness, that is, on the surface of the weaker plastic structural part, and opening a limited slot in the groove;

[0034] (2) Install the bead in the groove in step (1), and process the limit platform on the inner surface of the bead, that is, the surface matching with the groove;

[0035] (3) When assembling the groove in step (1) and the bead in step (2), fix it by dispensing glue and positioning the bumps, that is, add glue in the limit groove, and then connect the limit table with the limit The grooves are clicked and matched to complete the assembly of the bead and the groove, and do glue dispensing on the mating surface after the assembly is completed. The bead is made of aluminum alloy or spring steel.

Embodiment 2

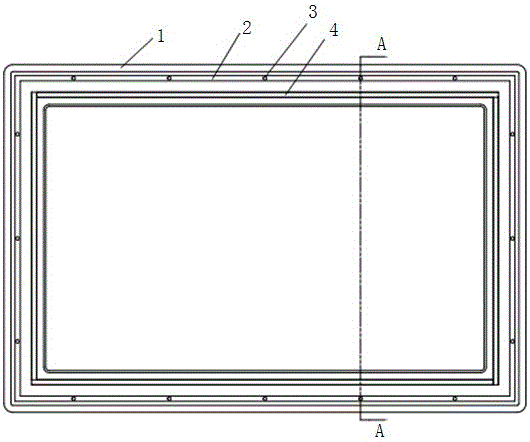

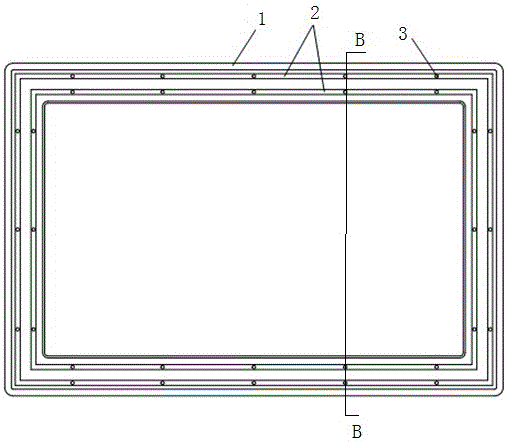

[0037] as attached Figure 1-8 As shown, the plastic structural part of the present invention adopts the plastic structural part 1 prepared by the method described in Example 1. A circle of grooves 2 is arranged on one side surface of the plastic structural part 1, and the bottom of the groove 2 is provided with a uniform The limit groove 3 is arranged, and the bead 4 is arranged in the groove 2. On one side of the bead 4, a uniformly arranged limit platform 5 is arranged. The limit platform 5 is cylindrical, and the limit platform 5 is clamped with the limit groove 3 Cooperate. The bead 4 is made of aluminum alloy or spring steel. There are five limiting grooves 3 in the length direction of the plastic structural member 1, and three limiting grooves 3 in the width direction. The number of limiting platforms 5 is less than or equal to the number of limiting slots 3 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com