Solar cell performance detection system

A technology for solar cells and solar panels, which is applied in circuits, electrical components, semiconductor/solid-state device testing/measurement, etc., can solve the problems of low detection efficiency and accuracy, and achieve high detection efficiency and accuracy and high detection efficiency. , the effect of high detection accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

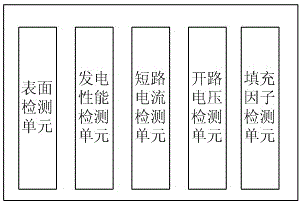

[0026] In the first embodiment, a solar cell performance detection system is provided, please refer to figure 1 , the system includes:

[0027] a surface detection unit, the surface detection unit is used to detect surface defects of the solar cell;

[0028] a power generation performance detection unit, the power generation performance detection unit is used to detect the power generation performance of the solar cell;

[0029] a short-circuit current detection unit, the short-circuit current detection unit is used to detect the anti-reflection film, the diffusion length of the base region, the junction quality, and the damaged layer;

[0030] an open-circuit voltage detection unit, which is used for edge corrosion and PN junction detection of the solar cell panel;

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com