Capsule quantum dots and light emitting method, preparation method and display apparatus

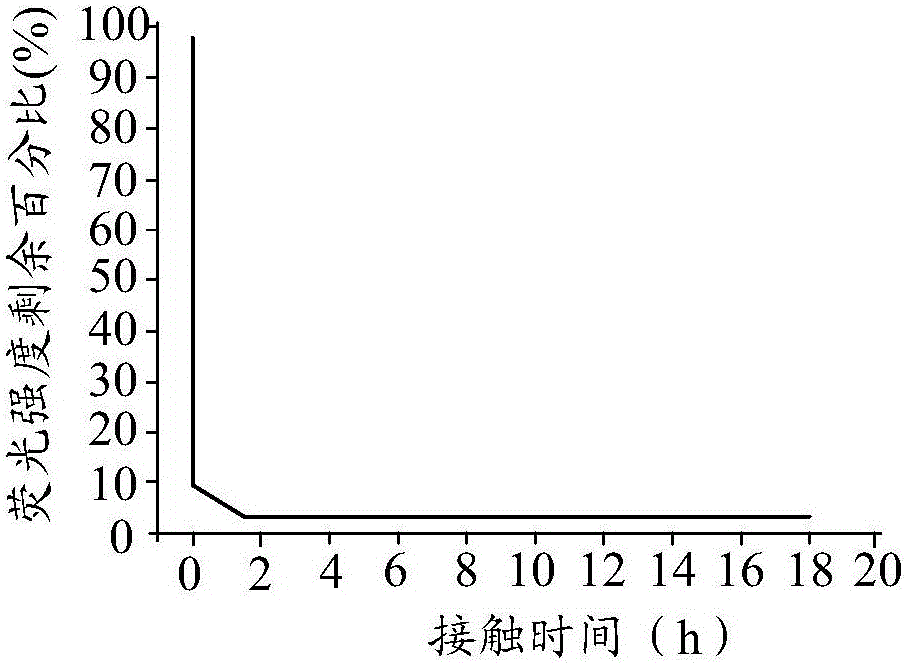

A technology of light-emitting diodes and display devices, which is applied in chemical instruments and methods, light-emitting materials, semiconductor devices, etc., and can solve problems such as inability to use, low luminous efficiency of quantum dot film layers, and fluorescence quenching

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

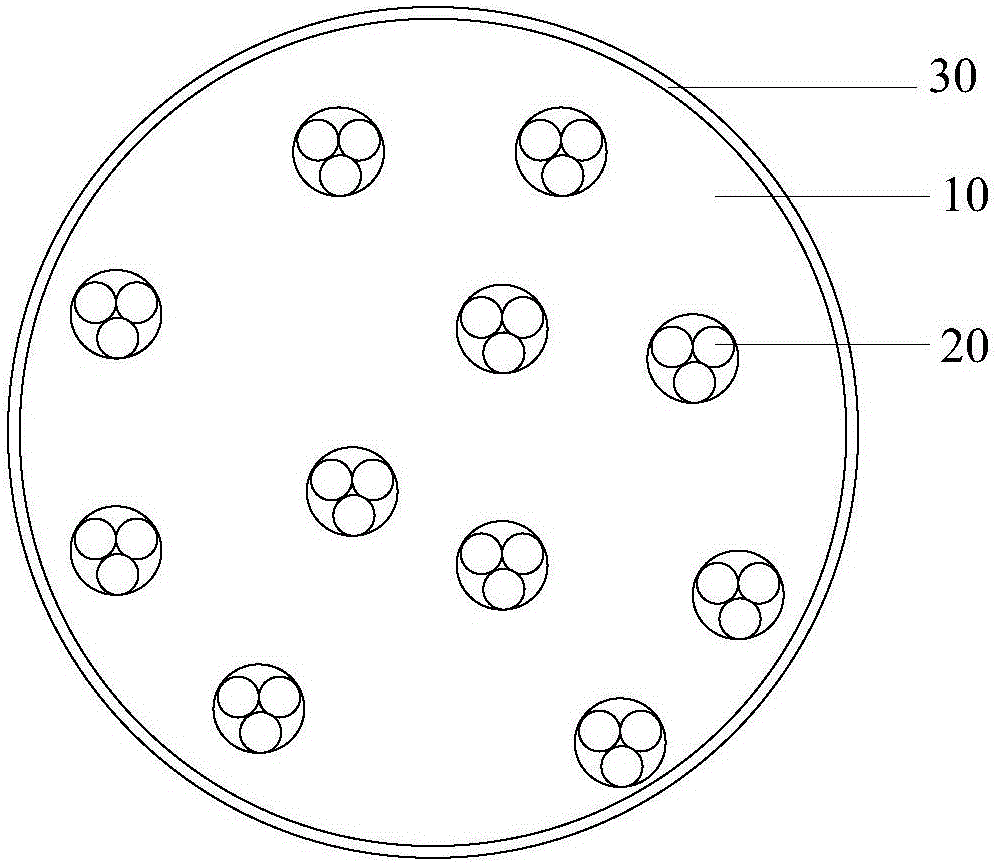

[0053] The embodiment of the present invention also provides a figure 2 The method for preparing capsule quantum dots is shown as Image 6 Shown, including:

[0054] S100. Mix the submicron or micron mesoporous material 10 and the quantum dots 20 in the thermosetting resin and stir them evenly.

[0055] Here, the quantum dots 20 can be fully absorbed in the pores of the mesoporous material 10 by uniform stirring.

[0056] Among them, for the amount of the mesoporous material 10, the thermosetting resin and the quantum dots 20, the quantum dots 20 can be fully absorbed in the pores of the mesoporous material 10, and the thermosetting resin can encapsulate the pores of the mesoporous material 10. .

[0057] In order to improve the utilization rate of the light emitted by the quantum dots 20 and prevent the light emitted by the quantum dots 20 located in the middle hole of the mesoporous material 10 from being absorbed or blocked by the mesoporous material 10 when exiting, it is prefera...

specific Embodiment

[0063] A specific example is provided below to describe the preparation method of capsule quantum dots in detail:

[0064] The silica mesoporous material and the quantum dots 20 are mixed in the thermosetting resin, and the mixture is sufficiently uniformly stirred, so that the quantum dots 20 are fully absorbed into the pores of the silica mesoporous material. Then the system is slowly heated. During the heating process, the system is stirred at a certain rate. Finally, the quantum dots can be encapsulated in the pores of the silica mesopores by means of cross-linking using thermosetting resin to form capsule quantum dots.

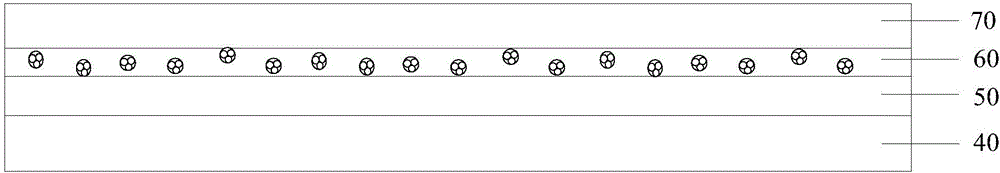

[0065] The embodiment of the present invention also provides a method for manufacturing a light-emitting diode, refer to image 3 As shown, it includes forming a first electrode 50, a quantum dot layer 60, and a second electrode 70 on the base substrate 40 in sequence.

[0066] Among them, such as Figure 7 As shown, forming the quantum dot layer 60 includes:

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com