A four-color bulk terminal crimping machine escapement

A terminal crimping machine and escapement technology, which is applied to circuit/collector parts, electrical components, circuits, etc., can solve the problems of low crimping qualification rate, complex escapement structure, and prolonged production cycle, etc. Achieve the effect of rapid and accurate terminal placement, high terminal pick-up efficiency, and low terminal damage rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

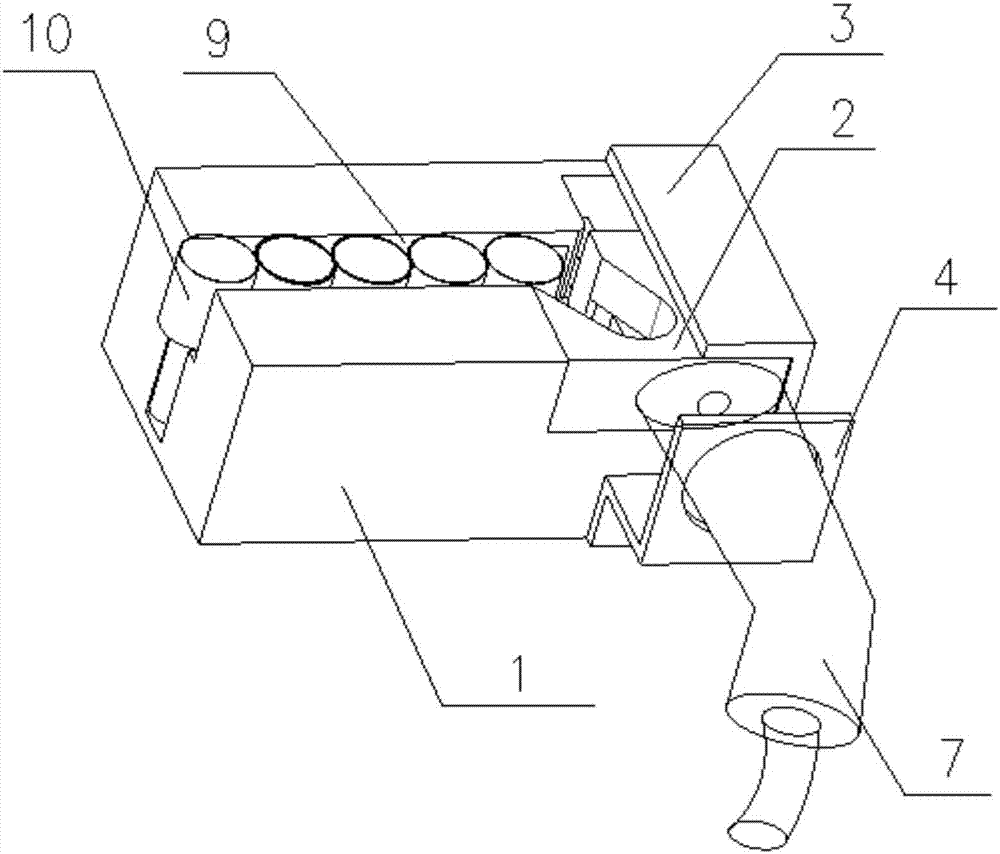

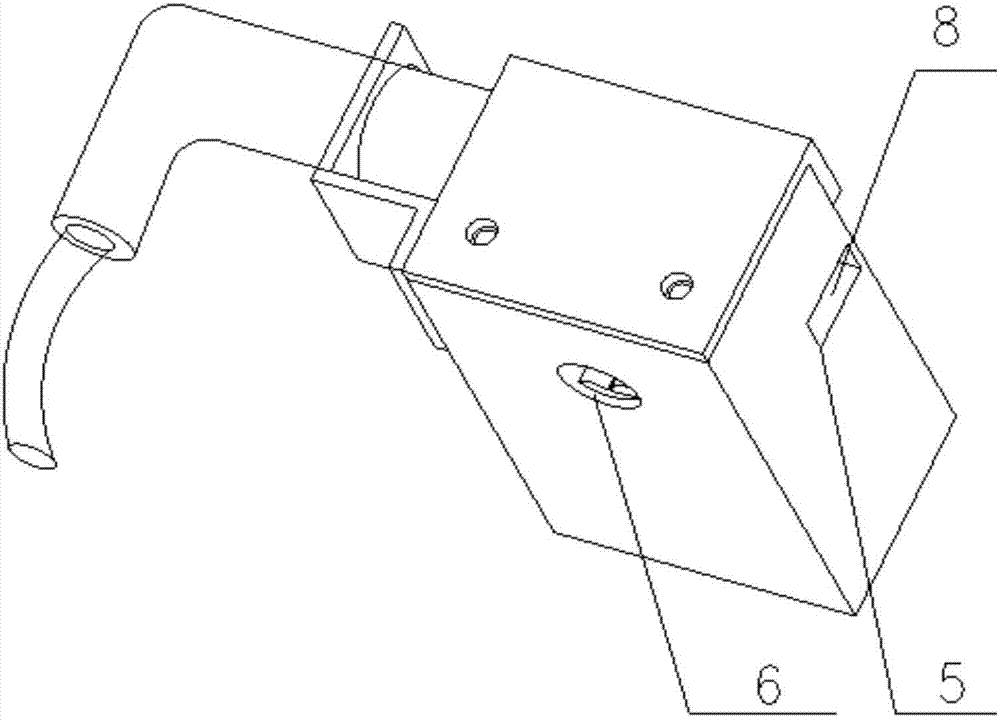

[0010] The main structure of the four-color bulk terminal crimping machine escapement involved in this embodiment includes an escapement block 2, an escapement bracket 1, a fixed plate 3, an escapement cylinder bracket 4, an escapement sensor hole 5, a drop hole 6, an escapement Vertical cylinder 7, escapement sensor 8, escapement groove 9 and terminal 10; the middle part of escapement bracket 1 with cuboid-shaped rigid structure has escapement groove 9, and terminals 10 are placed side by side in escapement groove 9; The escapement block 2 of the shape structure is slidingly connected with the escapement bracket 1, the escapement block 2 has a U-shaped opening, and the opening radius is greater than the radius of the cylinder head of the terminal 10; the fixed plate 3 of the U-shaped channel steel structure is fixedly arranged on the escapement One side of the vertical bracket 1, to prevent the escapement block 2 from falling off from the escapement bracket 1 when sliding; the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com