Method for fast making tea with cold water

A cold water and rapid brewing technology, which is applied to the field of rapid brewing of tea with cold water, can solve the problems of inconvenience and complex components, and achieve the effect of shortening the brewing time and good taste.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

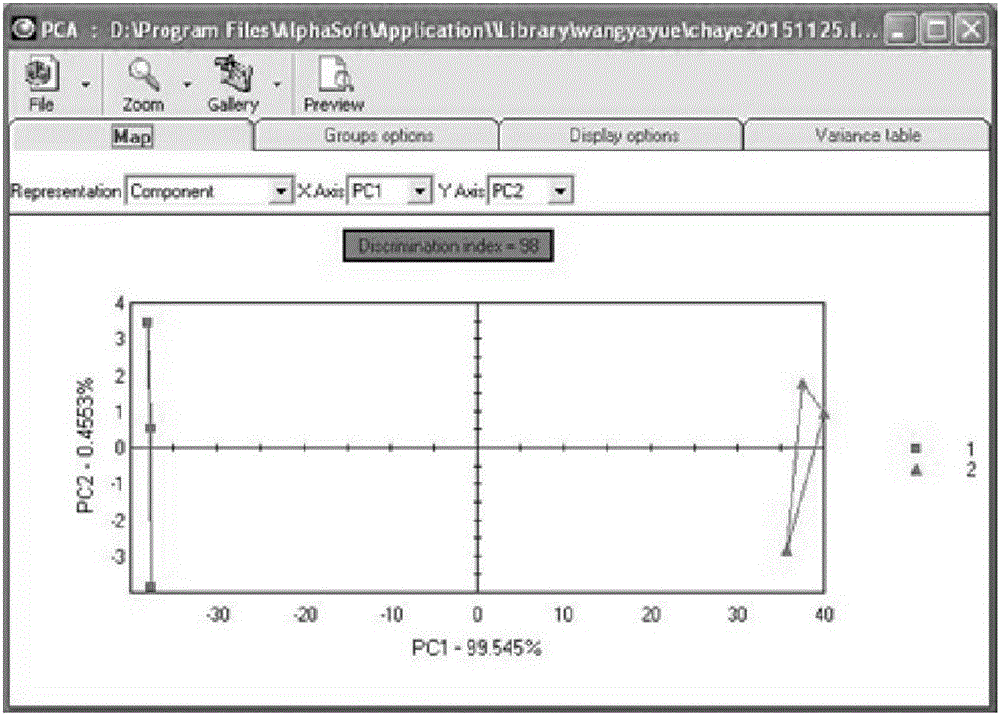

Image

Examples

Embodiment Construction

[0023] The specific embodiments provided by the present invention will be described in detail below in conjunction with the accompanying drawings.

[0024] The "tea" used for the purpose of the present invention selects general tealeaves as raw material, including green tea, black tea, jasmine tea, white tea, black tea, oolong tea, yellow tea, green tea, etc., and draws widely. In order to achieve the above object, the present invention provides the method for preparing tea product, and research method comprises the following steps:

[0025] 1. Screening of enzymes extracted from tea leaves

[0026] Add the same volume of enzyme solution to the tea leaves, and select the enzymes that have a significant effect on making tea with cold water, namely pectinase and cellulase.

[0027] 2. Determination of the ratio between the edible enzymes extracted from tea leaves

[0028] Pectinase: Cellulase = 2:3

[0029] 3. Determination of the ratio of water, tea leaves and enzymes

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com