Powder internal circulation homogenizing and disinfection device

A sterilization device and internal circulation technology, applied in the direction of solid separation, dissolution, sieving, etc., can solve the problems of powder homogenization, sterilization, sieving, etc., and achieve good sterilization effect, good mixing effect, maintenance The effect of air pressure stabilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

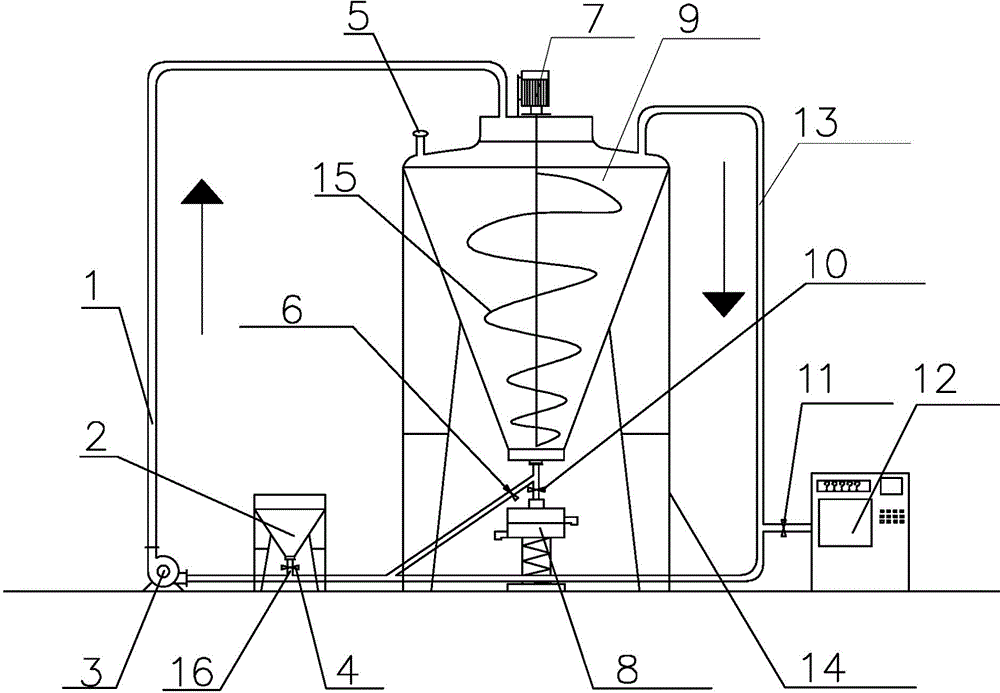

[0018] Such as figure 1 Among them, a powder internal circulation homogeneous sterilization device, including a bracket 14, a mixing tank 9 is installed on the bracket 14, a vibrating screen 8 is placed under the mixing tank 9, and the lower end of the mixing tank 9 passes through a valve with a third valve 10 The discharge pipe is communicated with the vibrating screen 8;

[0019] A feed hopper 2 is installed on the feed hopper bracket on one side of the support 14, and the feed hopper discharge pipe 16 of the feed hopper 2 is provided with a first valve 4, and the hopper discharge pipe 16 communicates with the air circulation pipeline 13, and the air flow One end of the circulation pipeline 13 is connected with the centrifugal fan 3, the other end of the air circulation pipeline 13 is connected with the mixing tank 9, one end of the material circulation pipeline 1 is connected with the feeding port of the mixing tank 9, and the other end of the material circulation pipeline ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com