Energy-saving sterilizing washing method

A laundry equipment, sterilization and disinfection technology, applied to other washing machines, chemical instruments and methods, washing devices, etc., to achieve the effect of avoiding cross-contamination and preventing environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

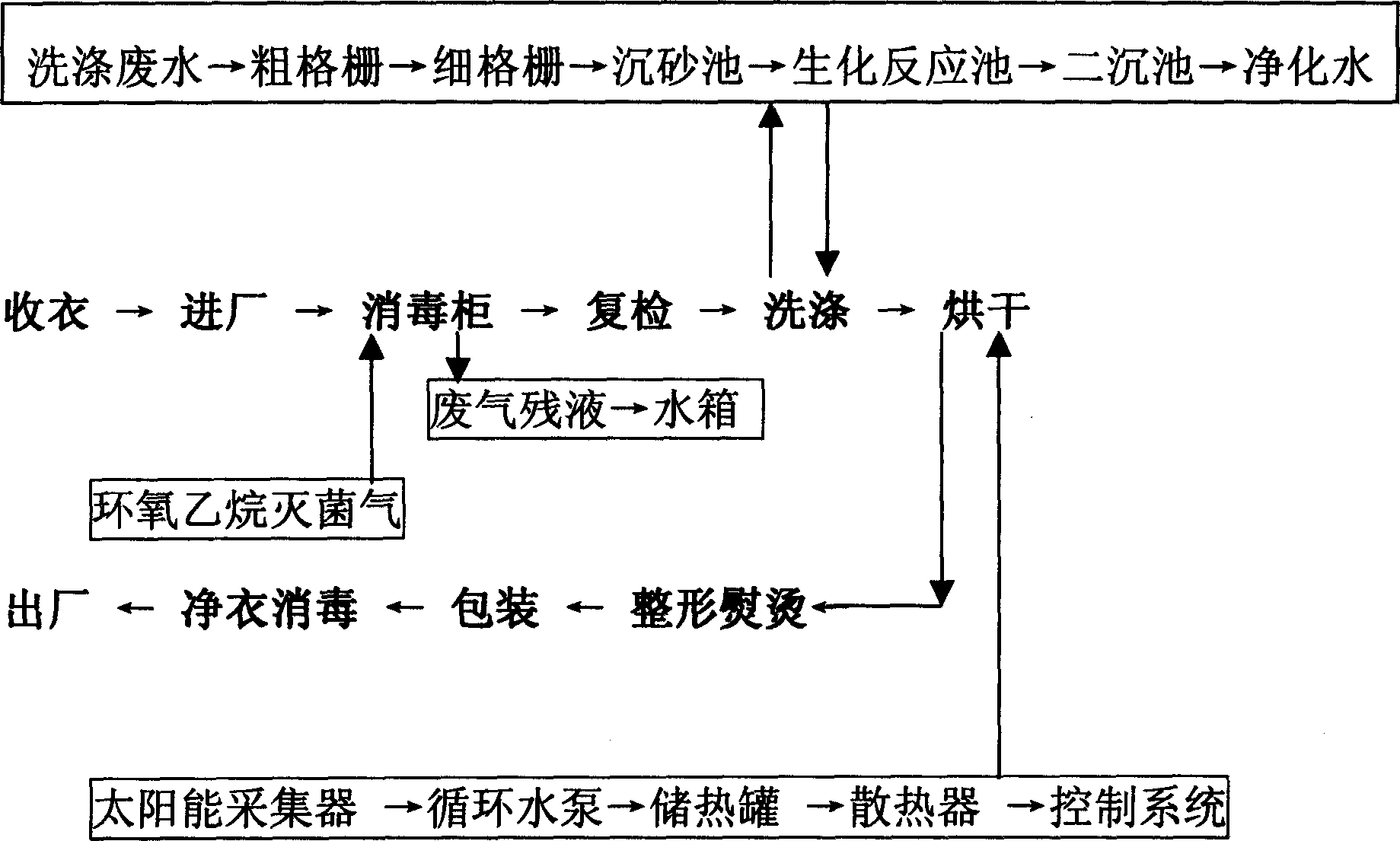

[0020] After the dirty clothes are received in the washing and dyeing factory, they first enter the sealed disinfection cabinet, and the disinfection cabinet is filled with sterilizing gas made of 20% ethylene oxide and 80% carbon dioxide, and the clothes are sterilized before washing, and the waste gas residue is It is discharged into the water tank, and after being sterilized, it is sent to the washing equipment, washed with circulating water after sewage treatment, and finally washed with tap water. The washed clothes are dried at 60°C by a dry solar heat collector, ironed, packed, cleaned and disinfected before leaving the factory.

[0021] The sewage discharged after washing first passes through the coarse screen to remove the large floating matter, the fine screen intercepts the fine floating matter, and the grit chamber removes the sand particles for pretreatment before biochemical treatment, and then enters the biochemical reaction tank. When using, first sprinkle the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com