Fully automatic preparation device for composite materials

A technology for composite materials and preparation devices, which is applied to mixers with rotating stirring devices, mixers, transportation and packaging, etc. It can solve the problems of reduced stiffness and stability, inaccurate batching, slow dripping speed, etc., and achieve batching The effect of improving accuracy, improving quality, and ensuring accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Embodiments of the present invention are further described below in conjunction with accompanying drawings:

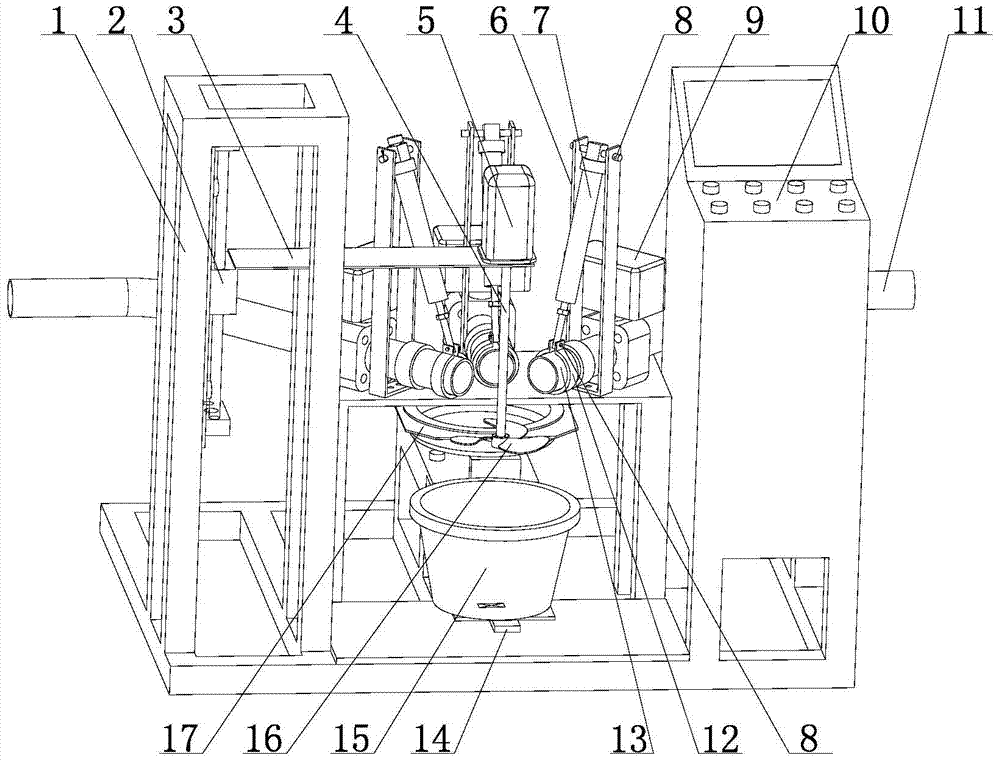

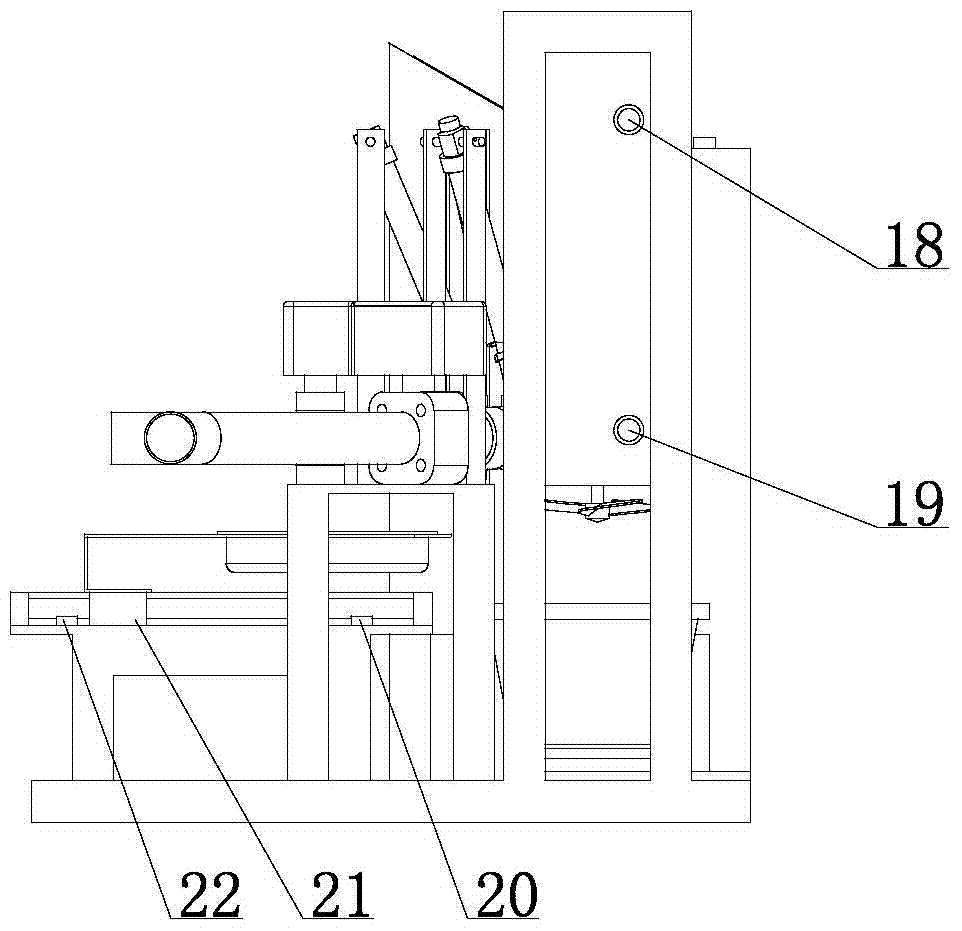

[0021] Such as figure 1 , 2 As shown, the composite material automatic preparation device of the present invention (which can be used for the preparation of composite materials used in wind turbine blades) includes a frame 1 and a batching bucket 15 located on the frame 1, a stirring mechanism and at least two groups of material delivery Pipe 11; Material quality measuring device 14 is arranged below batching barrel 15; Stirring mechanism is positioned at the top of batching barrel 15, and stirring mechanism is connected lifting drive mechanism; Automatic control valve 9 adopts pneumatic valve in the present embodiment on each material conveying pipe 11, Along the material conveying direction, a flexible pipe 13 is connected to the end of each material conveying pipe 11, and the discharge port of each flexible pipe 13 corresponds to the barrel mouth of the batc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com