Sample grinder for tissue sample grinding

A sample grinder and sample grinding technology, applied in the field of agricultural and biotechnological equipment, can solve the problems of wasting samples and liquid nitrogen, incomplete sample grinding, long sample grinding time, etc., and achieves convenient operation and eliminates the possibility of incompleteness. , the effect of shortening the grinding time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The specific structure of the present invention will be further described below in conjunction with the accompanying drawings and embodiments.

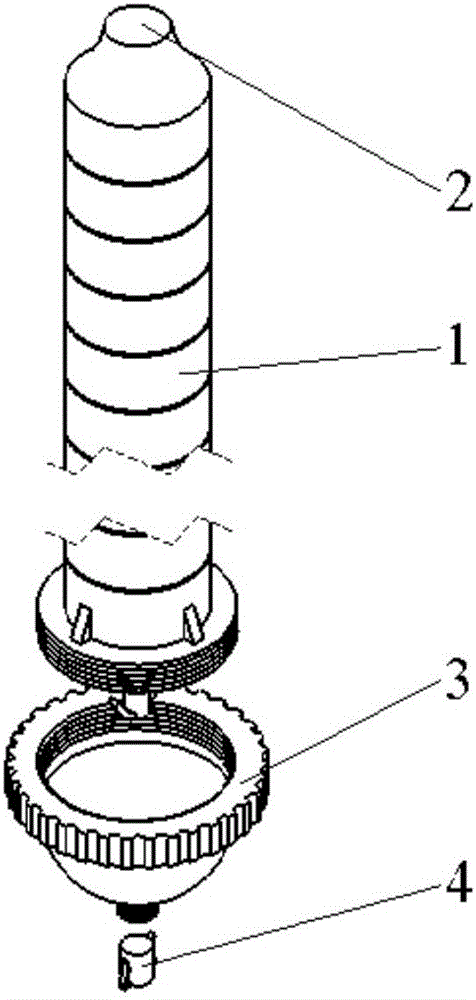

[0020] The main assembly structure of the tissue grinder is as follows: figure 1 As shown, it is characterized in that the tissue sample grinder consists of a hanging mill (1), a linkage line (2), a funnel (3) and a funnel plug (4); the hanging mill (1) passes through a 1.5-meter-long linkage line (2) Connected to the motor.

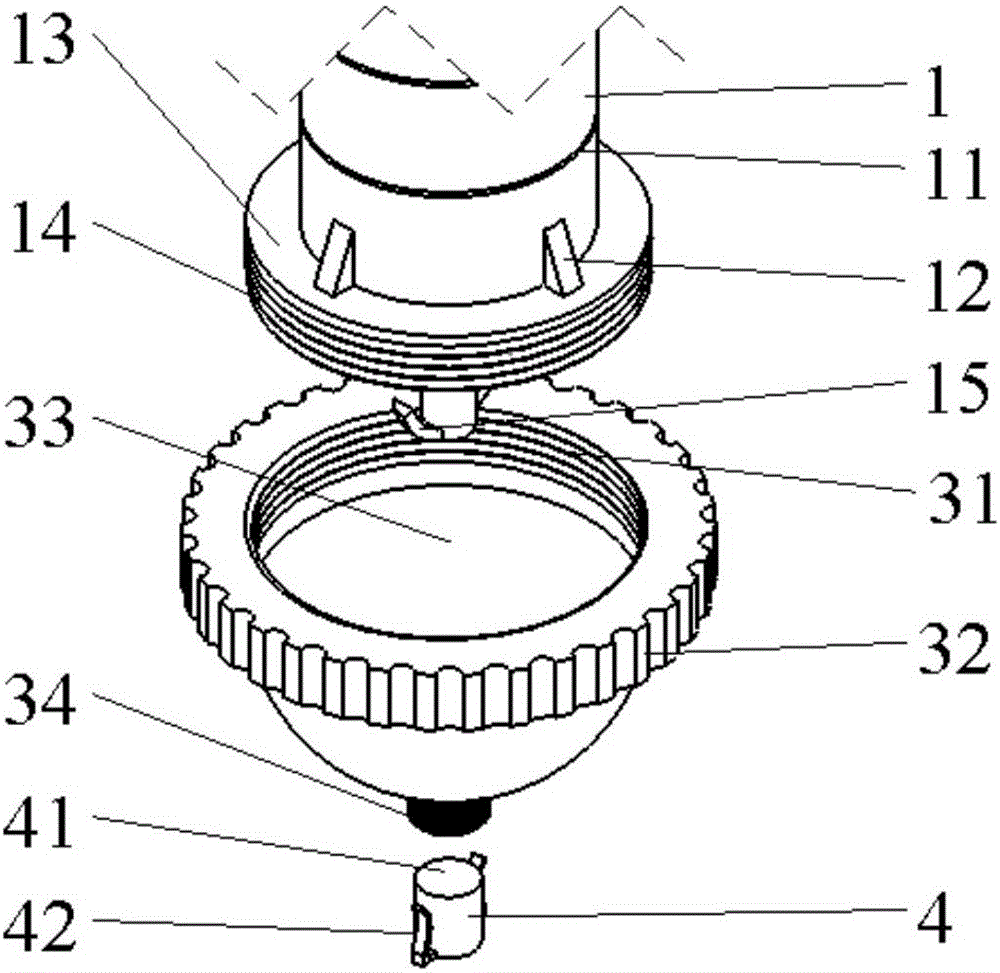

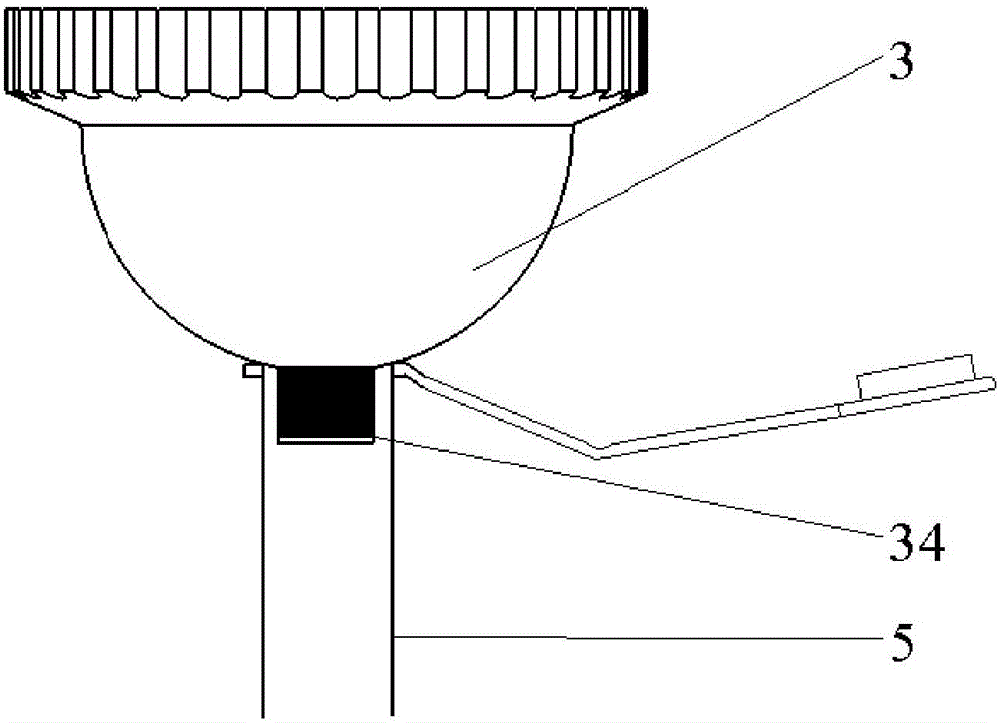

[0021] The lower assembly structure of the tissue grinder is as follows: figure 2 As shown, the handle of the hanging mill (1) is provided with a groove (11) to prevent hand sliding, and a chassis (13) is provided under the hanging mill (1), and the chassis (13) and the hanging mill (1) are strengthened Rib (12) is reinforced, and the outer side of chassis (13) is provided with external thread (14); Turning head (15) stretches out from the bottom center of chassis (13); The upper inner side of describe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com