Mobile single-roll crusher, control system and method thereof and material processing system

The technology of a single-roll crusher and a control method is applied to the control method and control system of a mobile single-roll crusher, a material handling system, a bulk material conveying system, and a mobile single-roll crusher. Deal with problems such as reduced system efficiency and overload

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

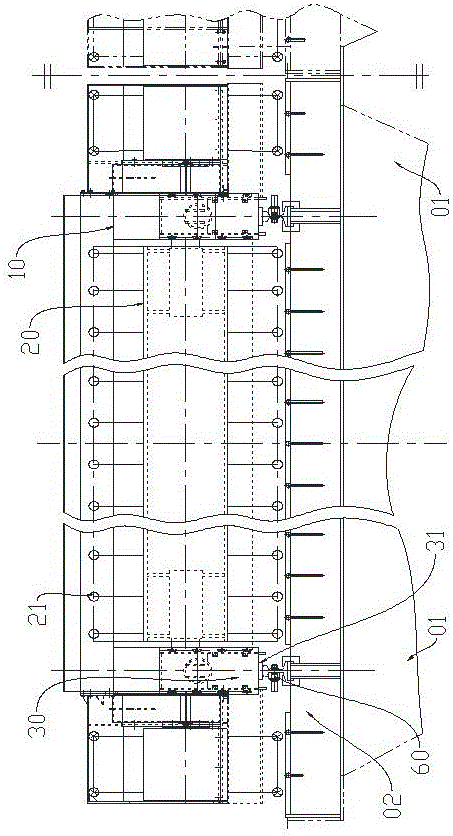

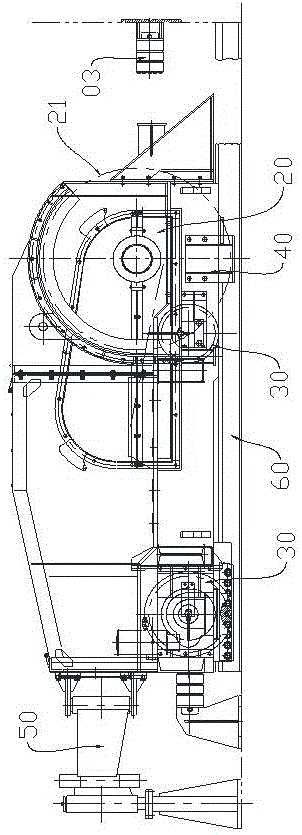

Image

Examples

no. 5 example

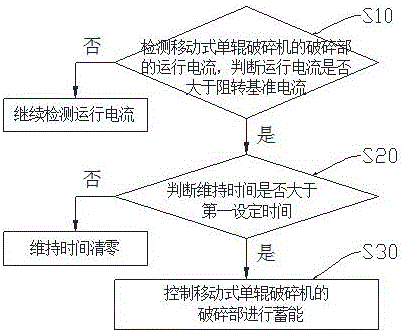

[0147] As mentioned above, the present invention can also use the running current of the walking part as a reference. Such as figure 1 , 2 As shown in and 9, the fifth embodiment of the control method of the mobile single-roll crusher provided by the present invention includes the following specific steps.

[0148] Step S210: Detect the running current of the walking part of the mobile single-roller crusher, and determine whether the running current is greater than its resistance rotation reference current, if yes, perform maintenance time counting; if not, continue to detect the running current of the walking part.

[0149] Step S220: Determine whether the maintenance time is greater than the first set time, if yes, execute step S230; if not, reset the maintenance time to zero. The first set time is generally 1-5 seconds, preferably 2-4 seconds, and more preferably 2-3 seconds.

[0150] Step S230, controlling the crushing part of the mobile single-roll crusher to store energy. Opt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com