Series grading magnetic separator

A magnetic separator and sorting technology, applied in the direction of magnetic separation, solid separation, chemical instruments and methods, etc., can solve problems such as inability to solve the contradiction between finished ore grade and recovery rate, metal loss, energy consumption, and recovery rate reduction, etc., to achieve Solve the effect of magnetic package and magnetic inclusion, improve recovery and improve grade

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

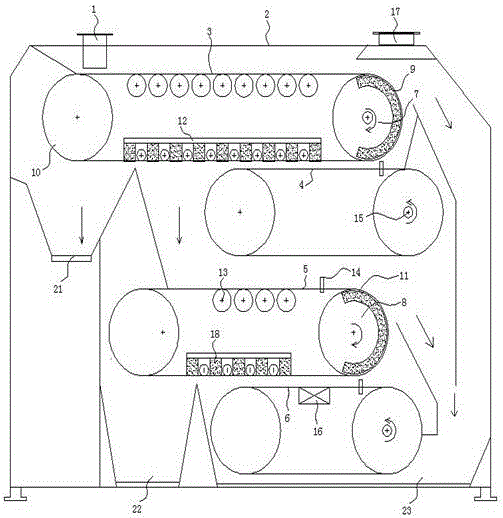

Embodiment 1

[0035] like figure 1 Shown, a kind of tandem classification magnetic separator comprises frame 2, and in said frame 2, first-level sorting belt 3, first-level conveying belt 4, second-level sorting belt 5 and two-level Conveyor belt 6; the first-level sorting belt 3 is located below the feed port 1, the discharge end of the first-level sorting belt 3 is provided with a tail-throwing mechanism-7, and the inner side of the lower belt of the first-level sorting belt 3 A sorting magnetic system-12 is provided, and a demagnetization zone is provided between the described tail-throwing mechanism-7 and the sorting magnetic system-12; a first-level conveyor belt 4 is arranged below the first-level sorting belt 3, and the first-level The feeding end of the conveyor belt 4 covers the discharge range of the tail-throwing mechanism-7, and the sorting magnetic system-12 covers the discharge end of the primary conveyor belt 4; the bottom of the primary conveyor belt 4 is provided with a sec...

Embodiment 2

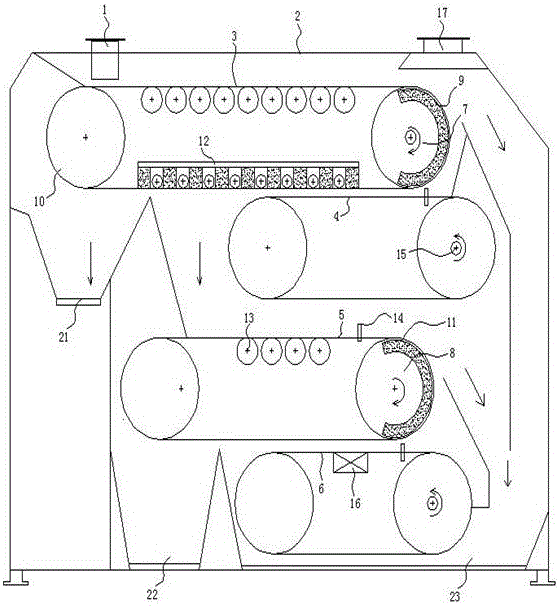

[0052] Embodiment two is the same as embodiment one, and its difference is that the sorting magnetic system two 18 arranged on the inner side of the lower belt of the secondary sorting belt 5 is cancelled, as figure 2 As shown, this series grading magnetic separator is mainly aimed at materials with higher grades, that is, after the materials are sorted by the primary sorting belt 3, the weak magnetic materials 202 and extremely weak magnetic materials 203 can be separated by the tail throwing mechanism 2 8 The second magnetization wheel 11 is completely sorted out and falls on the secondary conveying belt 6 after breaking away from the working range of the second magnetization wheel 11 and is sent into the middle ore mouth 22, so there is no need to sort again, which is conducive to reducing equipment costs.

Embodiment 3

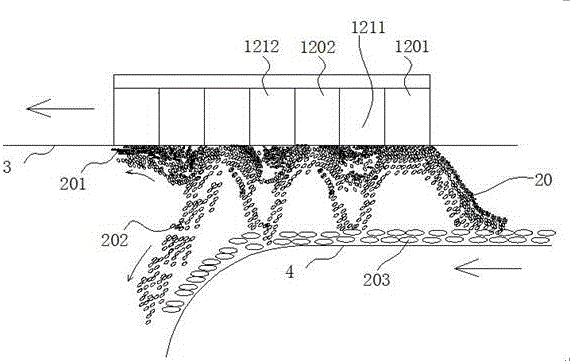

[0054] This embodiment is the same as Embodiment 1, the difference is that in this embodiment, there is no magnetic system adjustment mechanism 19, and the sorting magnetic system 1 12 is composed of a plurality of small magnetic systems arranged, and two adjacent small magnetic systems are arranged. The magnetic field strength of the magnetic system is different, so that the sorting magnetic system-12 has a plurality of magnetic field regions with different magnetic field strengths, such as image 3 and Figure 4 As shown, the magnetic field strengths of the small magnetic system 1201 and the small magnetic system 1202 are different. The magnetic field areas of the sorting magnetic system 12 are divided into strong magnetic areas, weak magnetic areas, strong magnetic areas, and weak magnetic areas along the direction of material transportation. A small magnetic system can be arranged horizontally on the inside of the primary sorting belt 3, or can be arranged in a zigzag shap...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Magnetic field strength | aaaaa | aaaaa |

| Magnetic field strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com