Mechanical arm cleaning device based on computer

A cleaning device and computer technology, applied in the direction of liquid cleaning method, dryer, drying gas arrangement, etc., can solve the problems of poor cleaning effect, inability to rotate workpieces at multiple angles, and inability to clean all holes and surfaces, etc., to achieve The effect of reducing the floor space and facilitating the operation of workers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

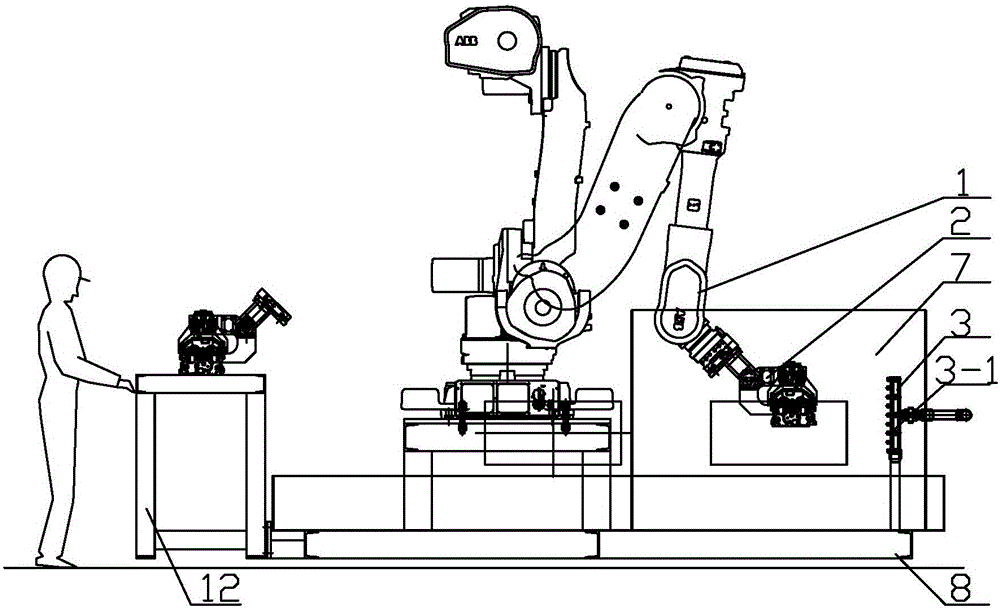

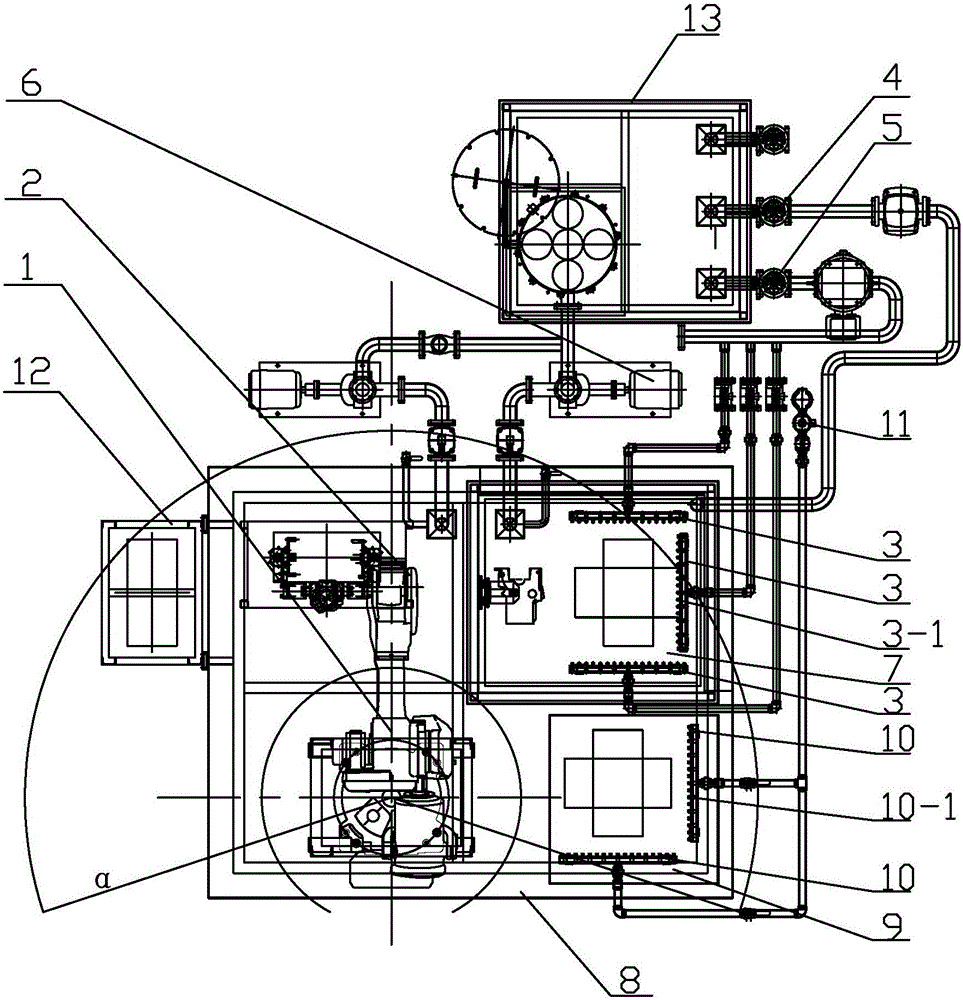

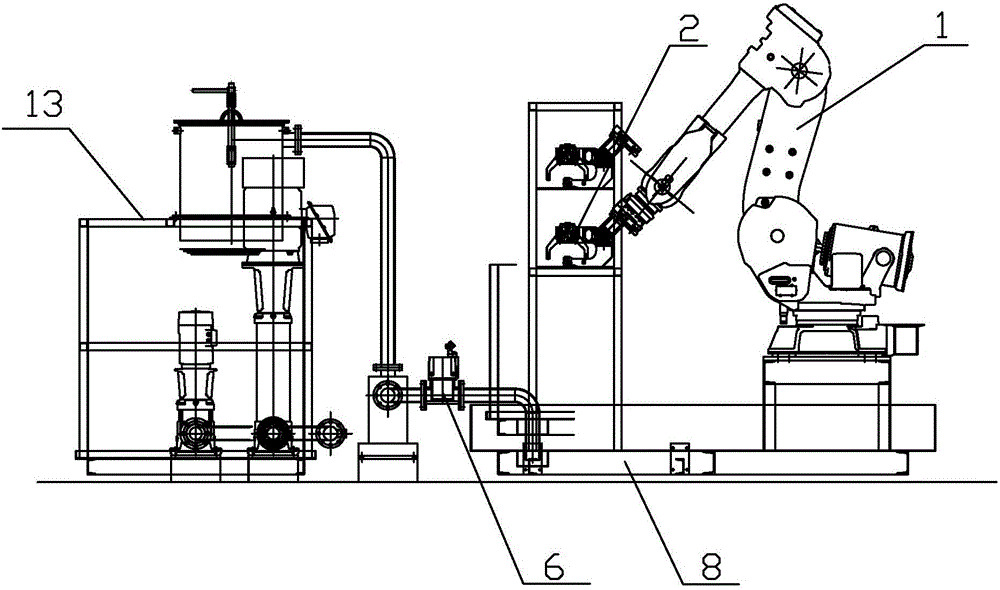

[0007] Specific implementation mode one: as Figure 1-6 As shown, a computer-controlled mechanical arm cleaning device described in this embodiment includes a six-axis mechanical arm 1, a turbulent flow cleaning pump 4, a fixed-point positioning cleaning pump 5 and a water tank 13, and the inlet end of the fixed-point positioning cleaning pump 5 It communicates with the water tank 13, and also includes a fixture 2, a plurality of cleaning plates 3, a cleaning chamber 7 and a workbench 8. The root end of the six-axis mechanical arm 1 is fixedly installed on the workbench 8, and the six-axis mechanical arm 1 The end is connected with the fixture 2, the cleaning chamber 7 is fixedly installed on the workbench 8, and it is ensured that the end of the six-axis robotic arm 1 can extend into the cleaning chamber 7 after the six-axis robotic arm 1 is deployed, and multiple cleaning plates 3 are arranged on the On the inner side wall of the cleaning chamber 7 or on the inner side wall ...

specific Embodiment approach 2

[0009] Specific implementation mode two: as Figure 1-6 As shown, the computer-controlled mechanical arm cleaning device in this embodiment also includes a drying chamber 9, two drying plates 10 and an air compressor 11, and the drying chamber 9 is fixedly installed on the workbench 8 , two drying boards 10 are located in the drying chamber 9, and the two drying boards 10 are arranged in an L shape, each drying board 10 is provided with several drying nozzles 10-1, each drying board The drying nozzle 10-1 on the 10 is connected with the output end of the air compressor 11 through a pipeline. This embodiment ensures that after the workpiece is cleaned, it can be sent into the drying chamber 9 by the six-axis mechanical arm 1 and quickly dried by the drying nozzle 10 - 1 on the drying plate 10 . Other components and connections are the same as those in the first embodiment.

specific Embodiment approach 3

[0010] Specific implementation mode three: as Figure 1-6 As shown, three cleaning boards 3 are arranged in the cleaning chamber 7 of the computer-controlled robotic arm cleaning device in this embodiment, and each cleaning board 3 is fixedly installed on an inner side wall of the cleaning chamber 7 . The cleaning nozzles 3-1 are densely arranged and can clean the workpiece thoroughly during the movement of the workpiece. Other components and connections are the same as those in the first embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com