Multifunctional comprehensive cutting device for plasma plate tube

A plasma plate and cutting device technology, applied in plasma welding equipment, auxiliary equipment, welding/cutting auxiliary equipment, etc., can solve the problems of inability to cut special-shaped pipes, cumbersome cutting process, difficult cutting processing, etc., and achieve great economy and practicality Sexual significance, simplification of production and preparation process, and the effect of reducing production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

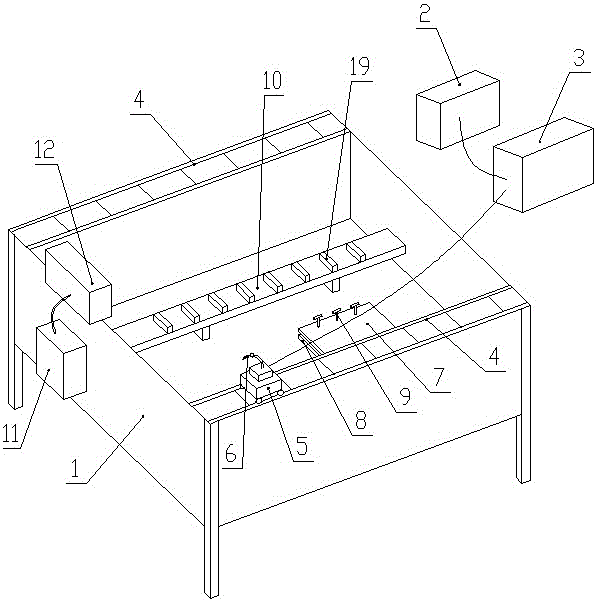

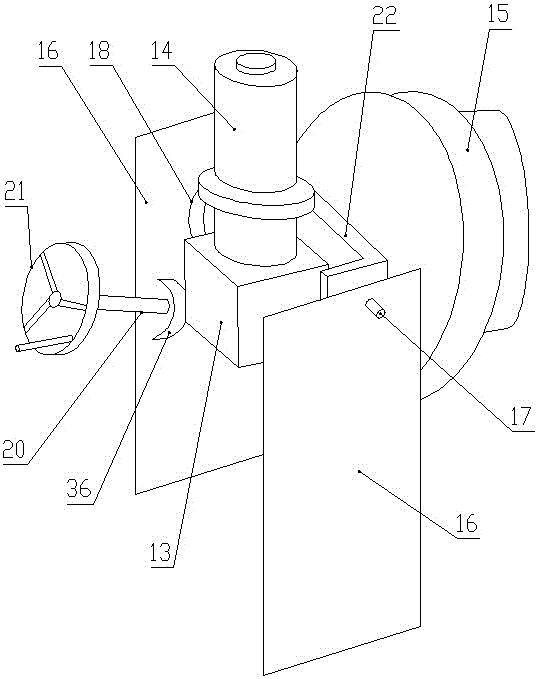

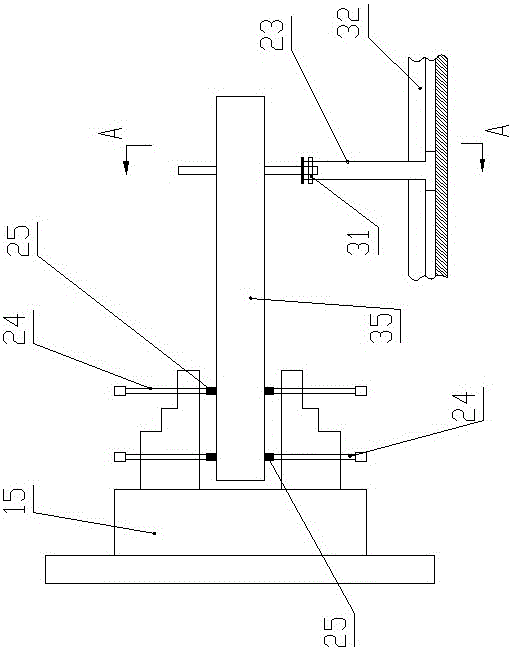

[0019] Such as Figure 1-6 As shown, the plasma plate tube multifunctional comprehensive cutting device of the present invention comprises a frame 1, and one side of the frame 1 is provided with an air compressor 2 and a plasma arc cutting machine 3, and the air compressor 2 is connected with the plasma arc cutting machine through a pipeline. 3-phase connection, a track is fixedly connected to the left and right sides of the upper surface of the rack 1, and each track is composed of two guide rails 4 arranged in parallel. The four guide rails 4 are all parallel to each other and arranged along the front and rear horizontal directions. The two guide rails 4 are rollingly connected with the cutting sports car 5, the cutting sports car 5 is fixedly connected with the cutting nozzle 6, the cutting nozzle 6 is connected with the plasma arc cutting machine 3 through the pipeline, and the inner wall on the right side of the frame 1 is equipped with a manual Press the leveling mechani...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com