Cutting Fluid Tank

一种切削液、液箱的技术,应用在车削设备、磨削/抛光设备、磨削/抛光安全装置等方向,能够解决切屑堆积在底部、流动停止、流速变慢等问题,达到维持有效容积、维护的负担变小的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

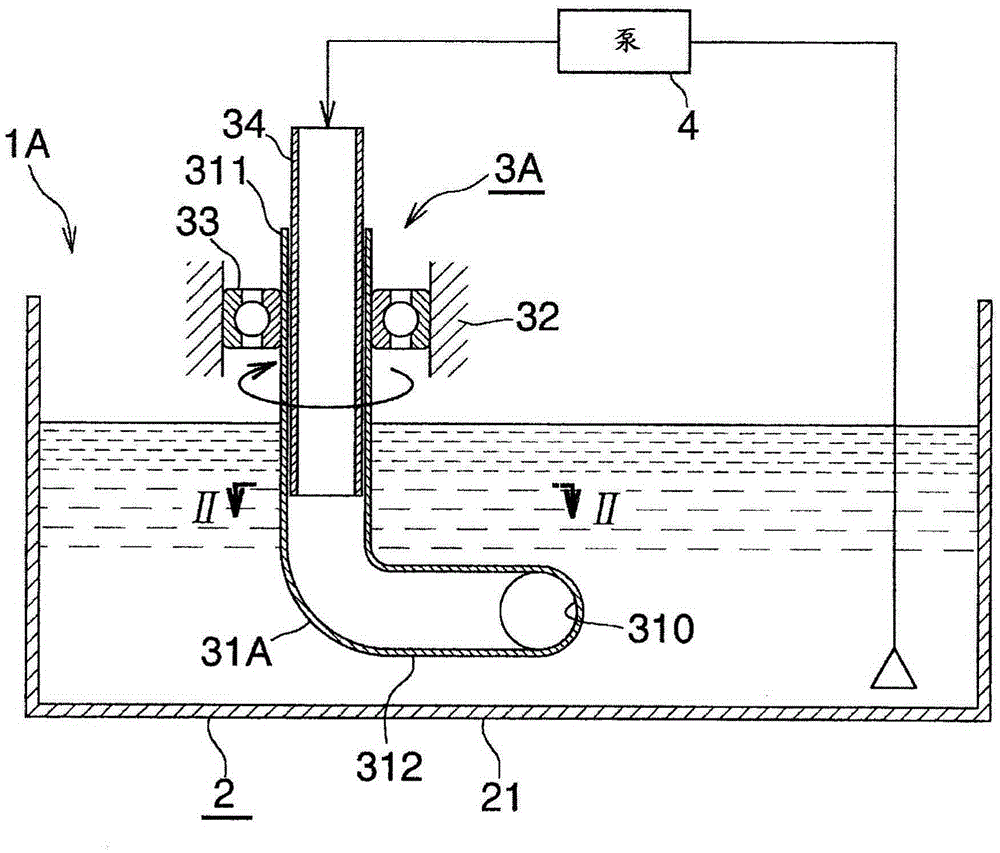

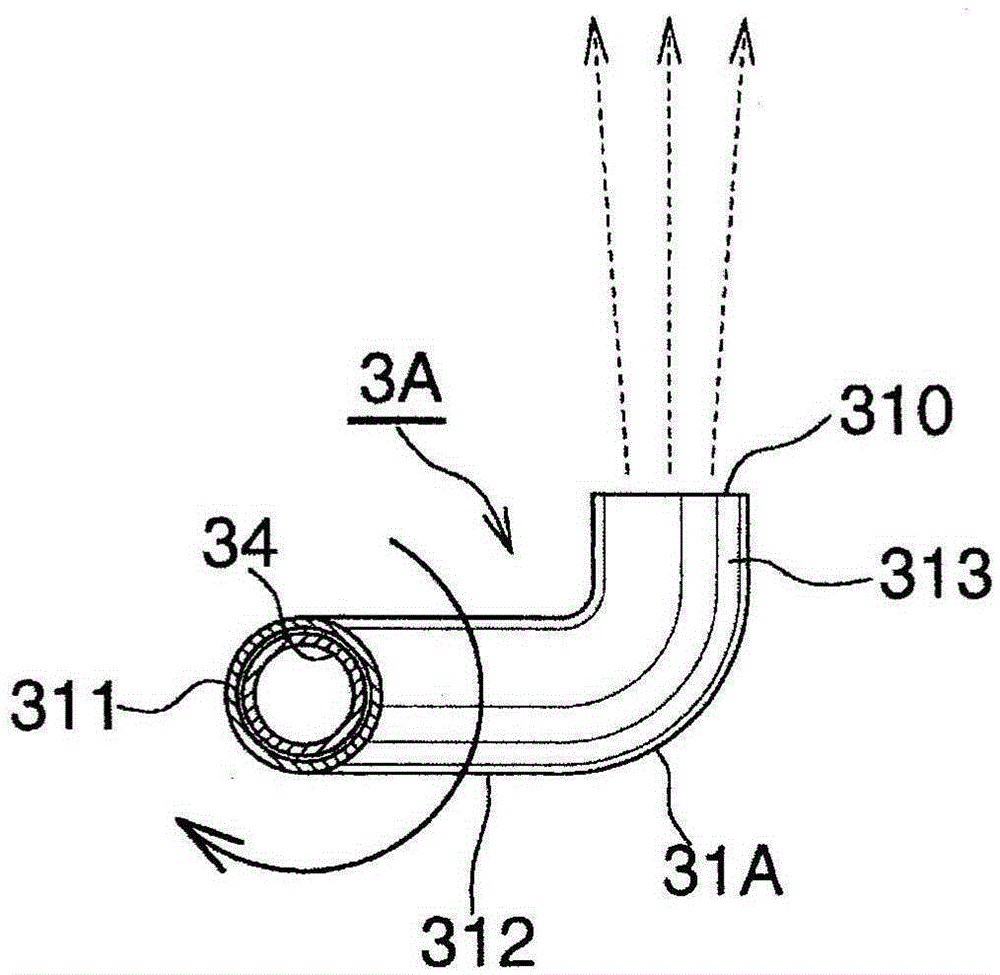

[0070] The cutting fluid tank 1A of the present embodiment has a tank body 2 and a fluid injection device 3A provided in the tank body 2 .

[0071] Although not shown in the figure, the tank main body 2 is disposed below the machining chamber of the machine tool, and the cutting fluid containing chips discharged from the machining chamber passes through a chip conveyor or a filter from a predetermined inflow point (for example, the cutting fluid flow of the chip conveyor) export) inflow.

[0072] In addition, in the box main body 2, there is a cutting fluid supply pump for supplying cutting fluid toward the machining chamber of the machine tool, and at a predetermined position (preferably, a position close to the cutting fluid supply pump), a centrifugal separator or a magnetic separator is provided. A chip separation device composed of a machine, etc.

[0073] In the tank main body 2, the entire cutting fluid including chips forms a liquid flow flowing from the inflow portio...

no. 2 approach

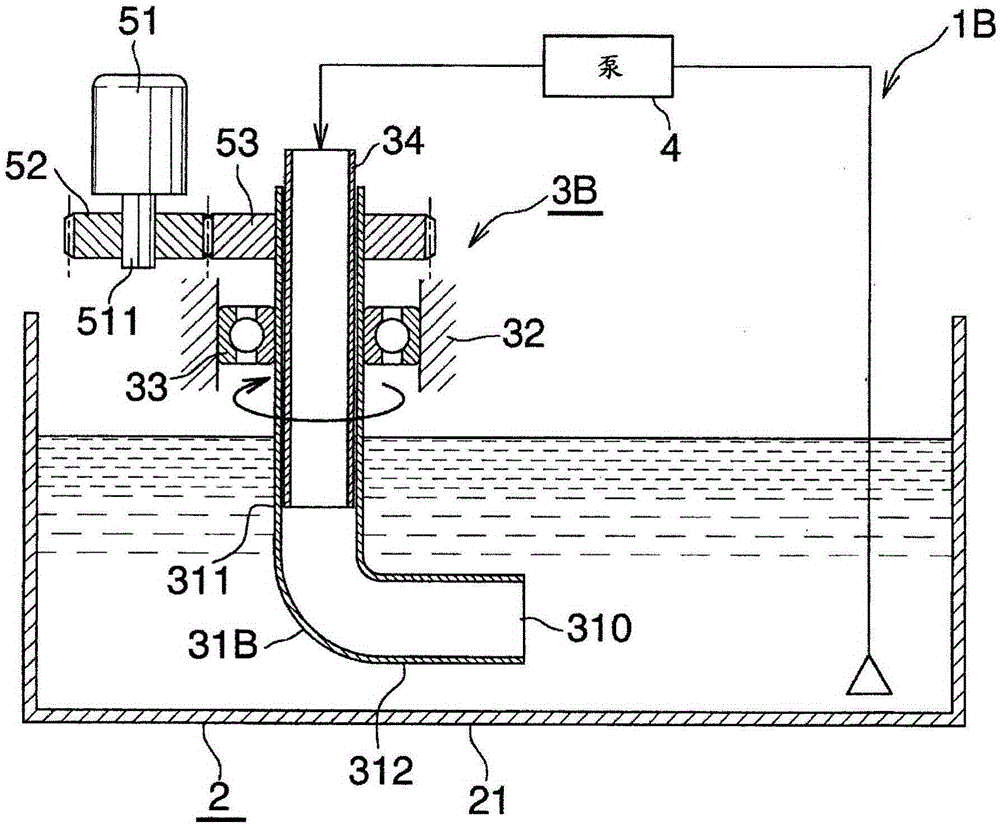

[0082] image 3 The second embodiment of the present invention is shown.

[0083] The cutting fluid tank 1B of the second embodiment is substantially the same as figure 1 and figure 2 The cutting fluid tank 1A of the first embodiment shown is the same.

[0084] That is, in the cutting fluid tank 1B of the present embodiment, the ejection head 31B of the fluid ejection device 3B does not have a curved end, and the ejection port 310 is formed by opening the front end of the lower horizontal cylindrical portion 312 . Therefore, the injection port 310 is oriented in a direction perpendicular to the vertical rotation axis of the injection head 31B.

[0085] Furthermore, the ejection head 31B is rotationally driven by the motor 51 . Specifically, the rotation of the output shaft 511 of the motor 51 is controlled by the drive gear 52 mounted on the output shaft 511 of the motor 51 and the driven gear 53 mounted on the upper end of the spray head 31B in mesh with the drive gear 5...

no. 3 approach

[0087] Figure 4 The third embodiment of the present invention is shown.

[0088] The cutting fluid tank 1C of the third embodiment is substantially the same as figure 1 and figure 2 The cutting fluid tank 1A of the first embodiment shown is the same.

[0089] That is, in the cutting fluid tank 1C of the present embodiment, the ejection head 31A of the fluid ejection device 3C is reciprocally rotated within a predetermined rotational angle. The rotation angle of the spray head 31A is limited to 90° by two stoppers 61 and 62 . The first stopper 61 is set so that, when the spray head 31A is positioned so that its spray port 310 faces Figure 4 The rotational position above ( Figure 4 The position shown by the solid line) is in contact with the side surface of the lower horizontal cylindrical portion 312 . In addition, the second stopper 62 is provided so that, when the ejection head 31A is positioned so that its ejection port 310 faces toward Figure 4 The rotational po...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com