Iron core of motor, motor and the manufacture method for iron core of motor

A technology for motors and iron cores, applied in the manufacture of stator/rotor bodies, magnetic circuit shapes/styles/structures, magnetic circuit static parts, etc., can solve the problem of magnetic property degradation, reduced magnetic properties, and increased wear and damage of punching dies, etc. problem, achieve the effect of reducing cogging torque and torque ripple, preventing the decline of magnetic properties, and improving the bending precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] (first embodiment)

[0035] Next, a first embodiment of the present invention will be described with reference to FIGS. 1 to 7. FIG.

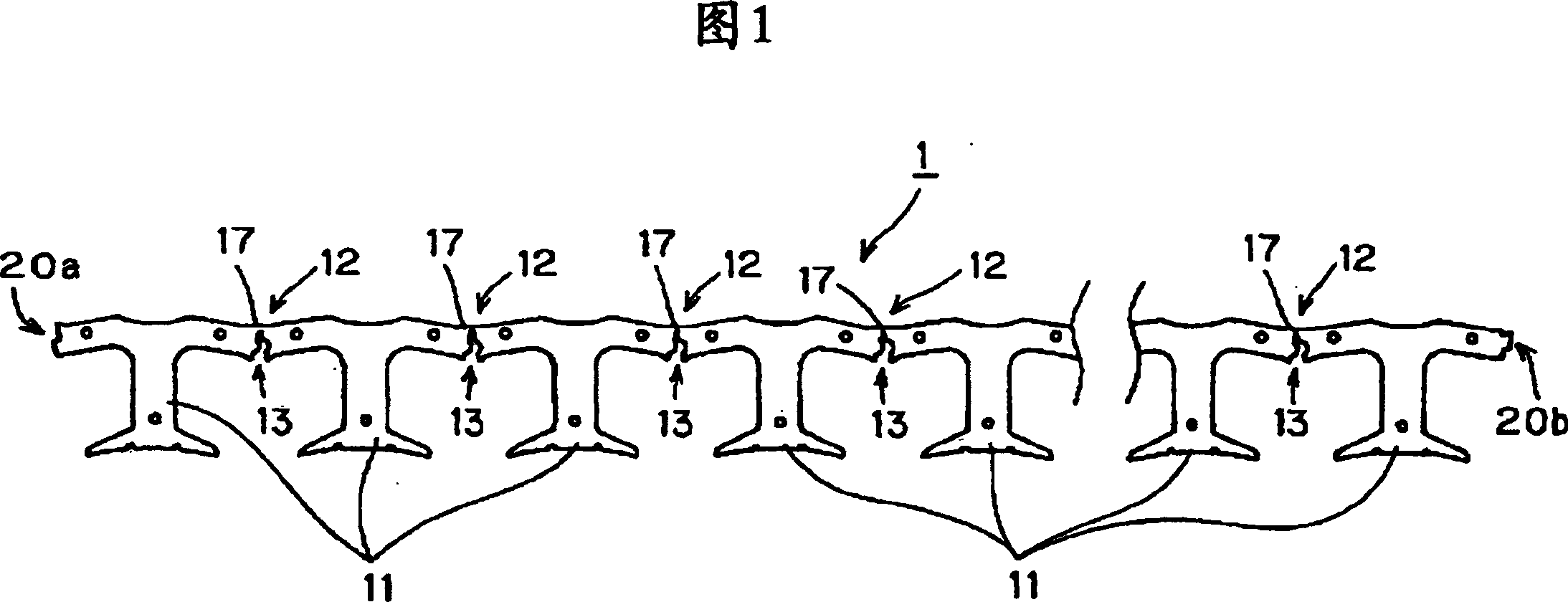

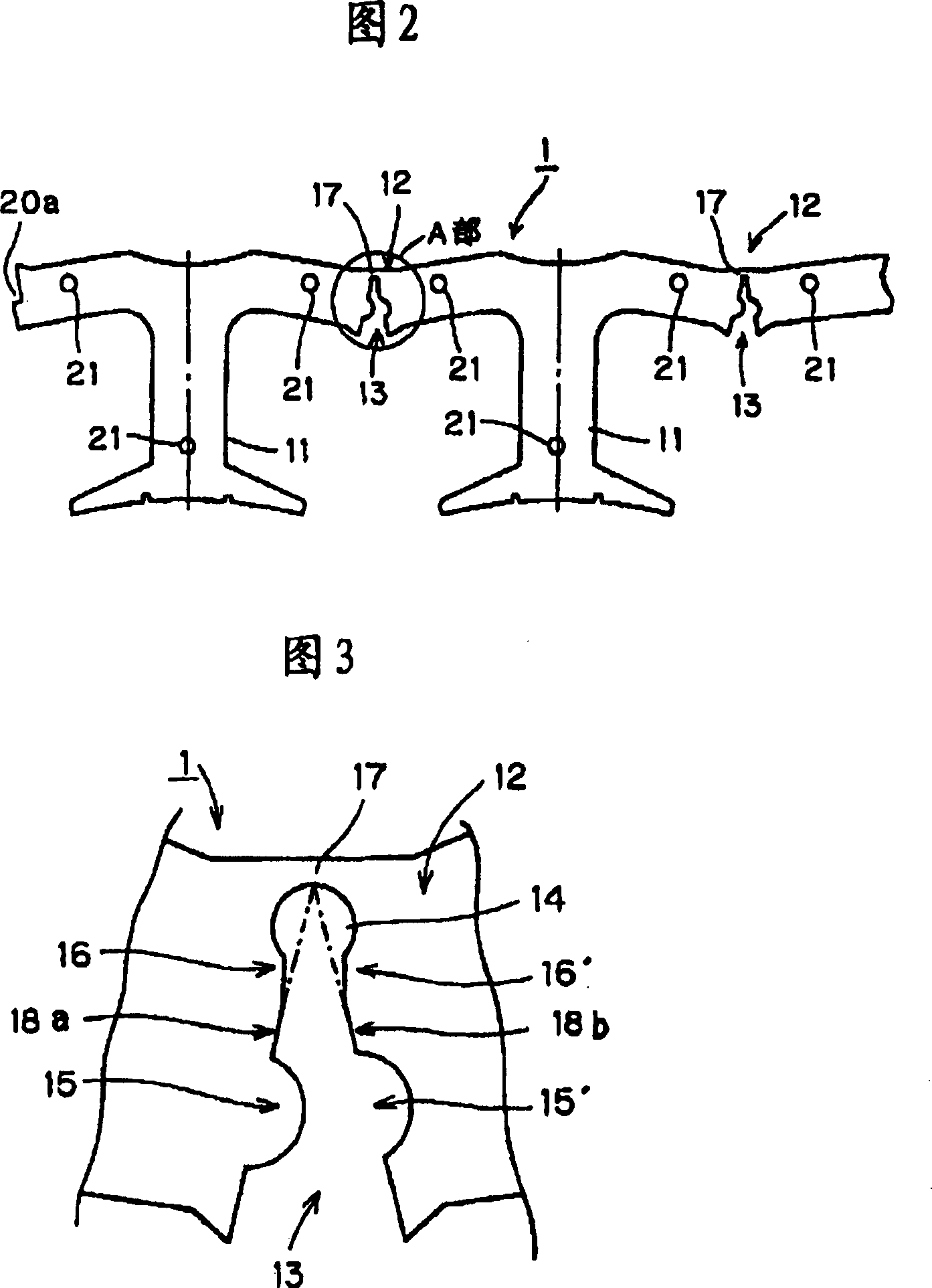

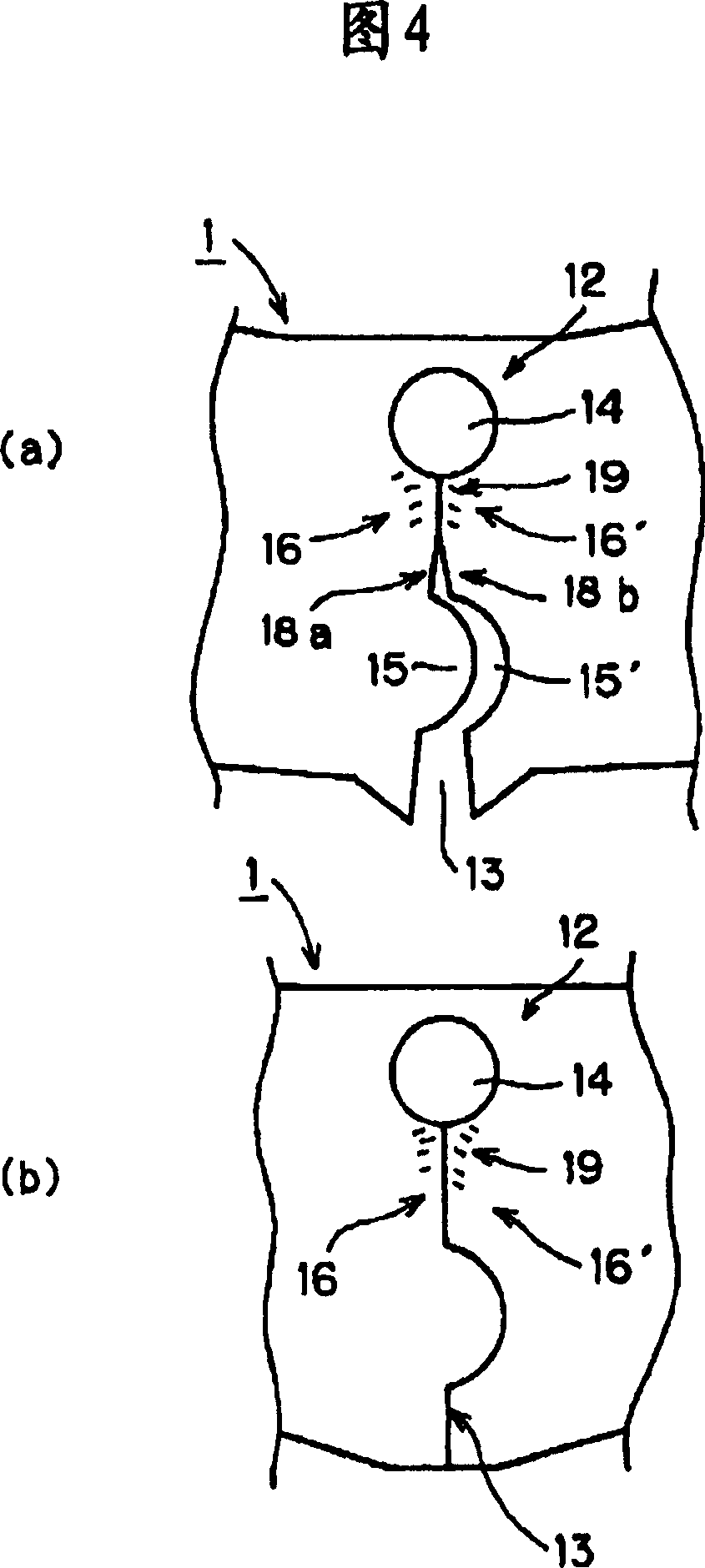

[0036] FIG. 1 is a plan view of a straight iron core 1 constituting an iron core of a brushless DC motor. FIG. 2 is a partial enlarged view of the straight core 1 shown in FIG. 1, and FIG. 3 is an enlarged view of a V-shaped notch (part A in FIG. 2) provided in the bent portion of the core.

[0037] As shown in FIGS. 1 and 2 , the straight core 1 is formed by punching laminated silicon steel sheets with a press using a punching die, and a plurality of T-shaped teeth 11 pass through the core having V-shaped notches 13 The narrow connecting portion 17 at the bottom of the notch portion 13 of the bent portion 12 is connected in a strip shape, and the hole 21 for screwing is opened at a predetermined position, and the connecting portion for bending the straight iron core 1 to be connected into a ring shape is provided at both ends. 20a, 20...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com