Gear shifting performance offline detecting device of manual transmission

A manual transmission and detection device technology, which is applied in the direction of manipulators, program-controlled manipulators, chucks, etc., can solve the problems of expensive manipulators and inability to quickly detect the shifting performance of manual transmissions, and achieve efficient and accurate gear selection/shifting with low cost , the effect of compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described in detail below in conjunction with the accompanying drawings. Wherein, the descriptive terms such as up, down, left, right, etc. are used for the description, with the purpose of helping readers to understand, but not intended to limit.

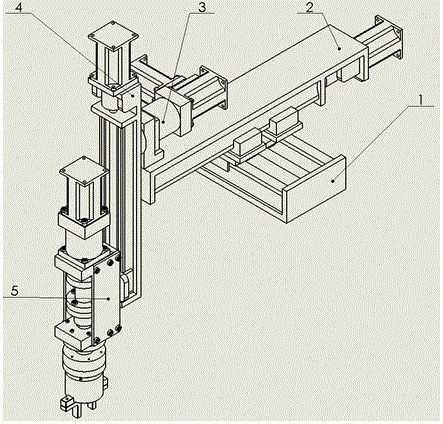

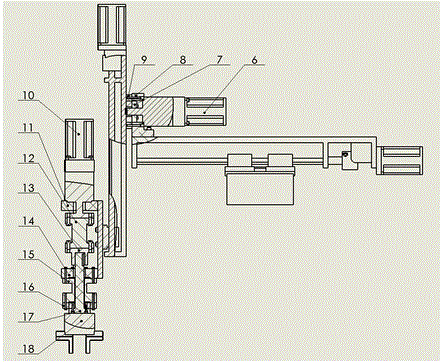

[0021] During specific implementation: if figure 1 , 2 As shown, the off-line detection device for shifting performance of a manual transmission of the present invention includes: an X-axis linear module 1, a Y-axis linear module 2, a rotary joint 3, a Z-axis linear module 4, a centering and torque measuring mechanism 5, Stepping motor and reducer 6, adapter block 7, support body 8, first cross roller bearing 9. Stepper motor and reducer 10, first support 11, torque sensor 12, adapter block 13, second support 4, three-way force sensor 15, cross roller bearing 16, mandrel 17 and two-jaw cylinder 18, etc. .

[0022] The X-axis linear module 1 is connected with the Y-axis linear module ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com