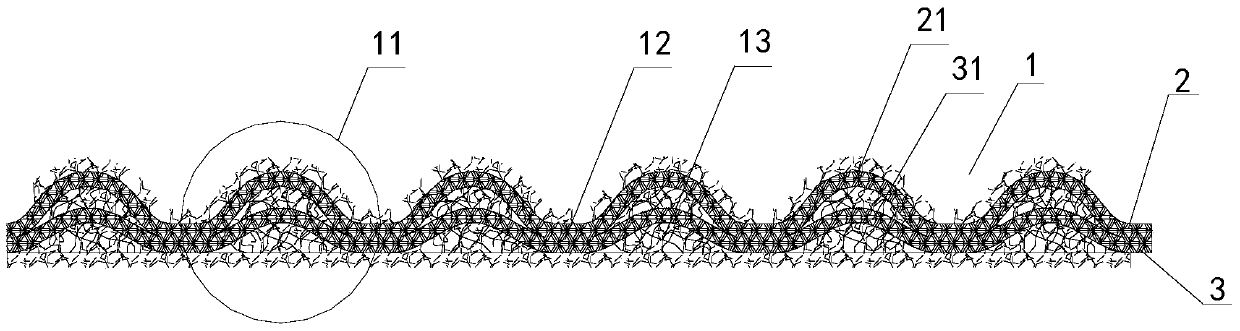

A composite nonwoven fabric and its manufacturing device

A technology for manufacturing devices and nonwovens, applied in lamination devices, clothing, apparel, etc., can solve the problems of poor absorption rate and air permeability of hygiene products, achieve improved appearance, high production efficiency, and increase surface area Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

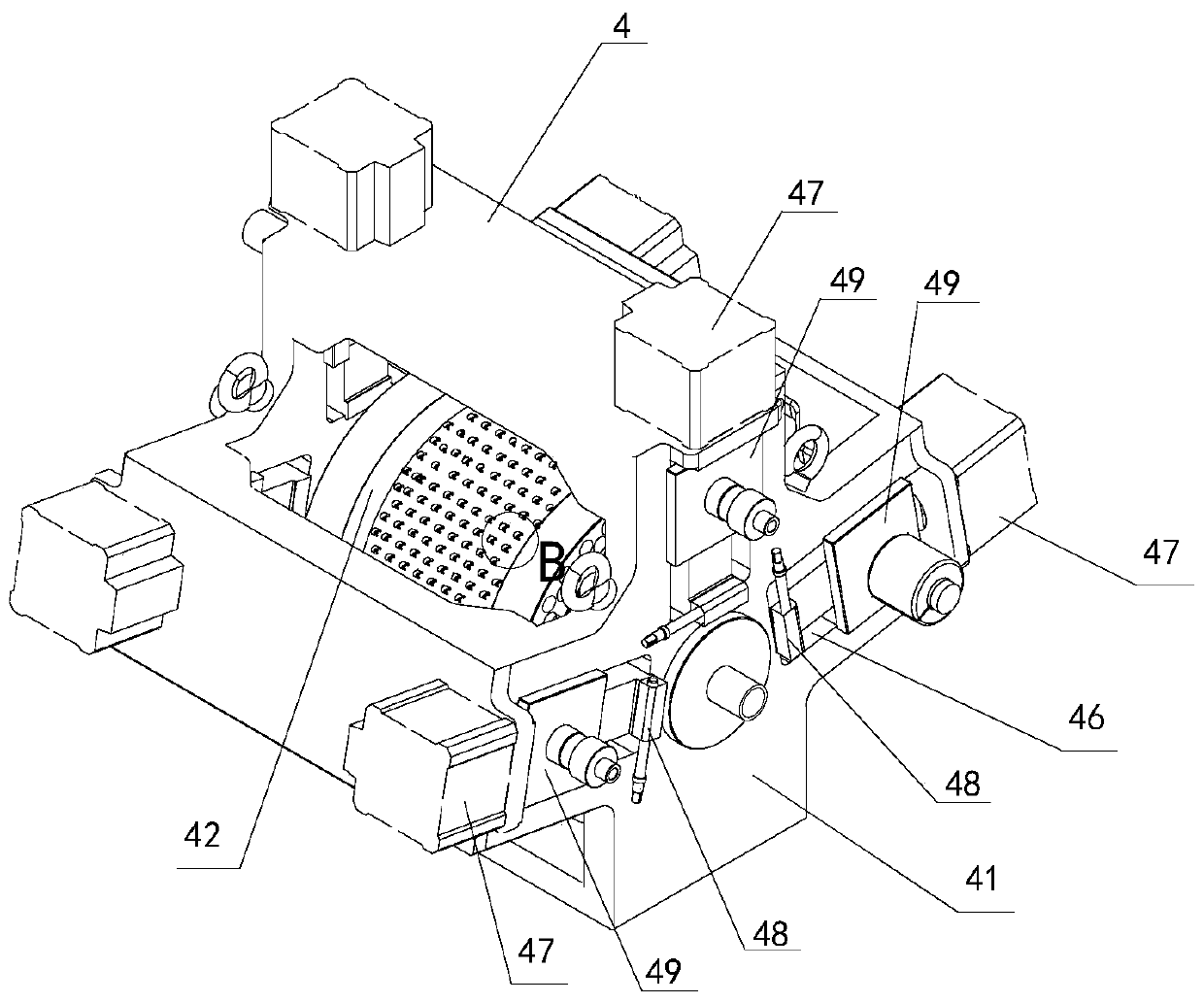

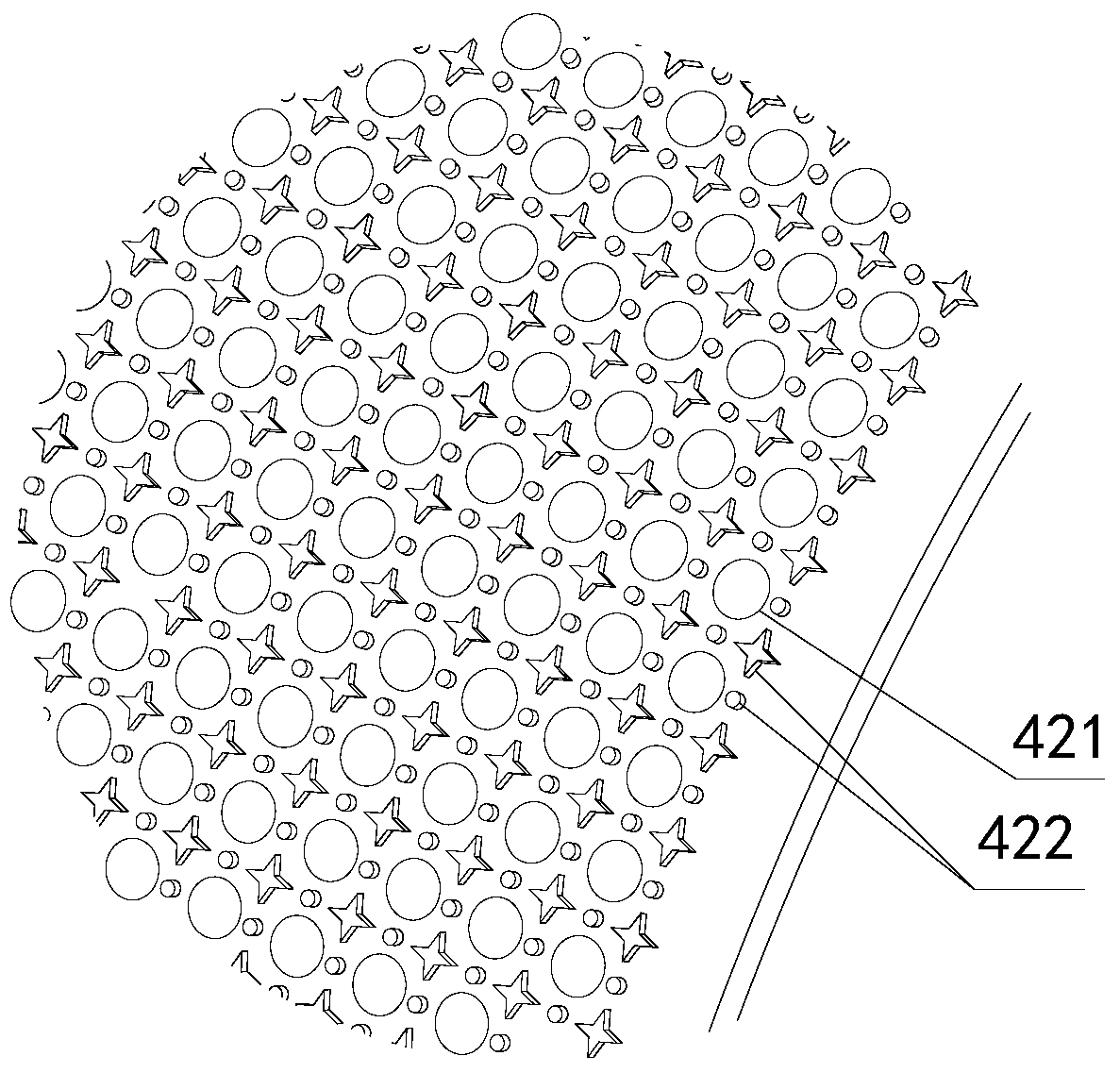

[0035] Such as Figure 2-8 As shown, the device for manufacturing the above-mentioned composite nonwovens includes a support frame 41, a bottom roll 42 arranged on the support frame 41, and the bottom roll 42 is provided with a first patterned roll 43 and a second patterned roll in sequence along its rotation direction in the circumferential direction. 44 and flat roller 45, the surface of the bottom roller 42 is provided with a number of concave holes 421, the gap between the concave holes 421 on the bottom roller 42 is provided with pattern protrusions 422, and the surface of the first pattern roller 43 is provided with The third protrusion corresponding to the concave hole 421, the surface of the second pattern roller 44 is provided with a fourth protrusion 441 corresponding to the concave hole 421, the third protrusion and the concave hole 421 engagement, the fourth protrusion 441 is engaged with the concave hole 421, the height of the fourth protrusion 441 is lower than t...

Embodiment 2

[0045] Such as Figure 9 and 10 As shown, as another embodiment of the present invention, the device for manufacturing the above-mentioned composite nonwoven fabric includes a support frame 41, a bottom roll 42 arranged on the support frame 41, and the bottom roll 42 is sequentially arranged along its rotation direction in the circumferential direction. The first embossed roller 43, the second embossed roller 44 and the ultrasonic generator 7, the surface of the bottom roller 42 is provided with several concave holes 421, and the gap between the concave holes 421 on the bottom roller 42 is provided with patterned protrusions 422, The surface of the first embossed roller 43 is provided with a third protrusion corresponding to the concave hole 421, and the surface of the second patterned roller 44 is provided with a fourth protrusion 441 corresponding to the concave hole 421, When working, the third protrusion engages with the recessed hole 421, and the fourth protrusion 441 en...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com