Furnace temperature and air supply amount control system for gasifying furnace in biomass gasification power generation device

A technology for a power generation device and a control system, which is applied in the field of biomass gasification power generation devices, can solve problems such as unreasonable structural design, uneven air supply to a gasifier, and unbalanced power generation, and achieves simple use of structure and balanced power generation. , the effect of voltage stabilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

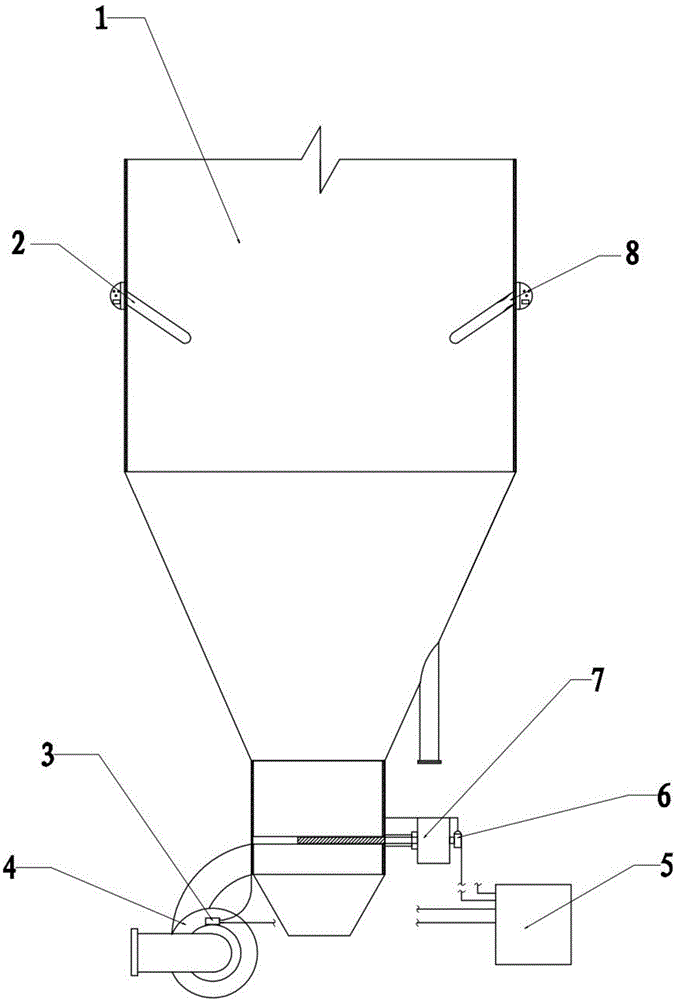

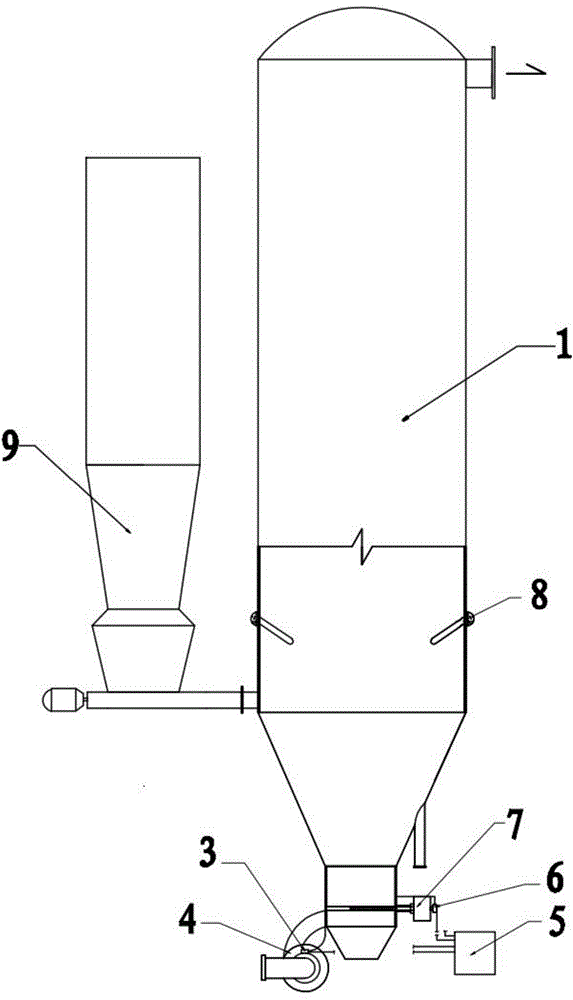

[0015] as attached Figure 1-2 In the shown embodiment, the straw gasification furnace body 1 of the present invention, blower 4, slide valve 7, slide valve electric controller 6, slide valve temperature controller 8, blower controller 3, blower temperature controller 2, slide valve 7 Installed at the bottom of the furnace body 1 of the straw gasification furnace, the slide valve 7 is connected with the slide valve electric controller 6, the blower 4 is equipped with the blower controller 3; the blower temperature controller 2 and the slide valve temperature controller 8 are respectively symmetrically installed Connected to the wall of the straw gasification furnace body 1; the slide valve temperature controller 8 and the blower temperature controller 2 are respectively connected to the signal output terminal of the general controller 5 of the power generation device by electrical signal lines, the blower controller 3 and the slide plate The valve electric controllers 6 are re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com