Spray hanger attitude laser detector

A detector and hanger technology, which is applied in the field of spray hanger attitude laser detector, can solve the problems that no objective data cannot be further analyzed, reduce the operating rate of the spraying line, and the success rate of inspection and correction is low, so as to improve the detection efficiency and automation degree, does not interfere with normal production, and facilitates the effect of correction work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be further illustrated below in conjunction with the accompanying drawings and specific examples. The examples are implemented on the premise of the technical solutions of the present invention. It should be understood that these examples are only used to illustrate the present invention and are not intended to limit the scope of the present invention.

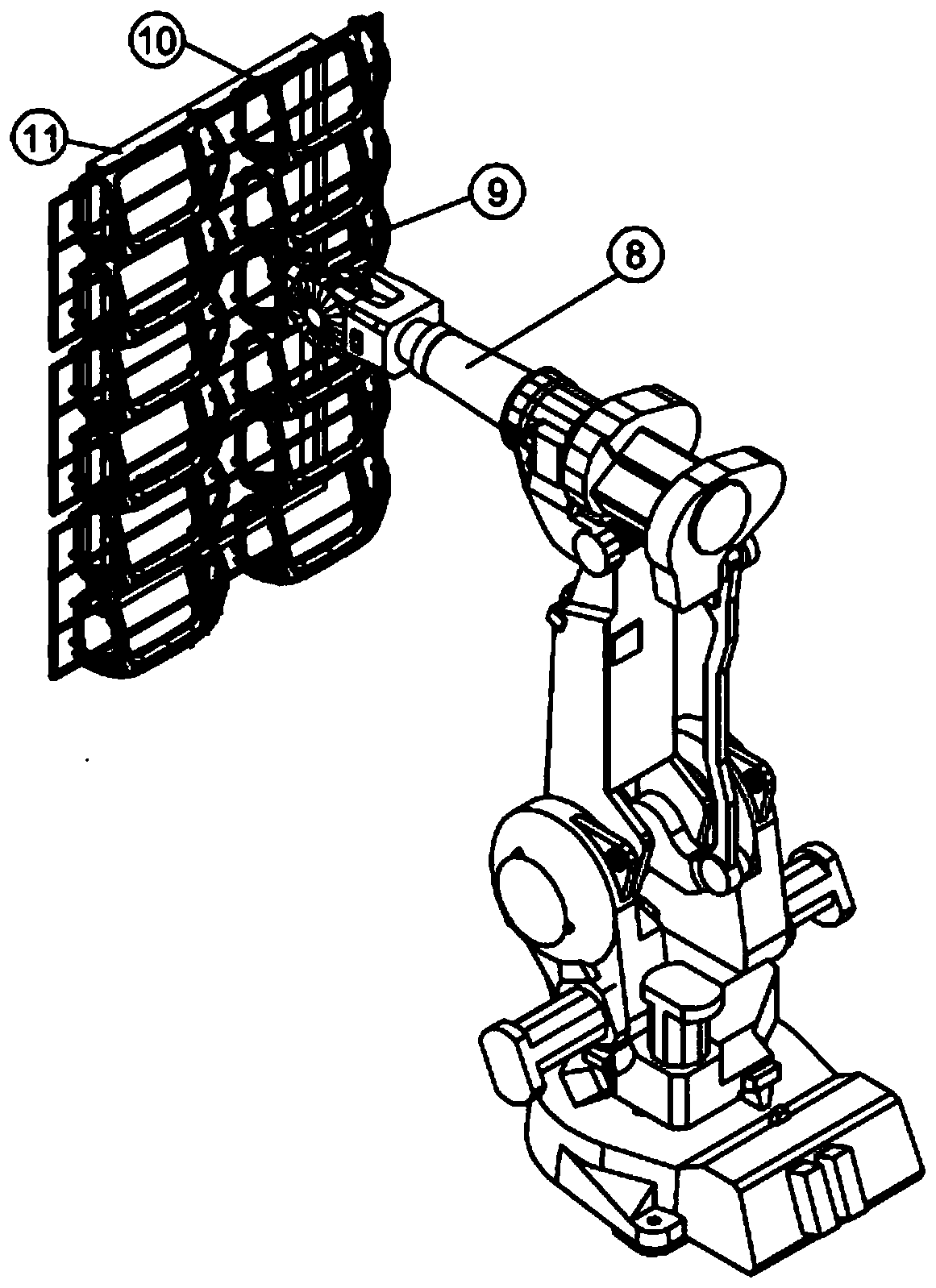

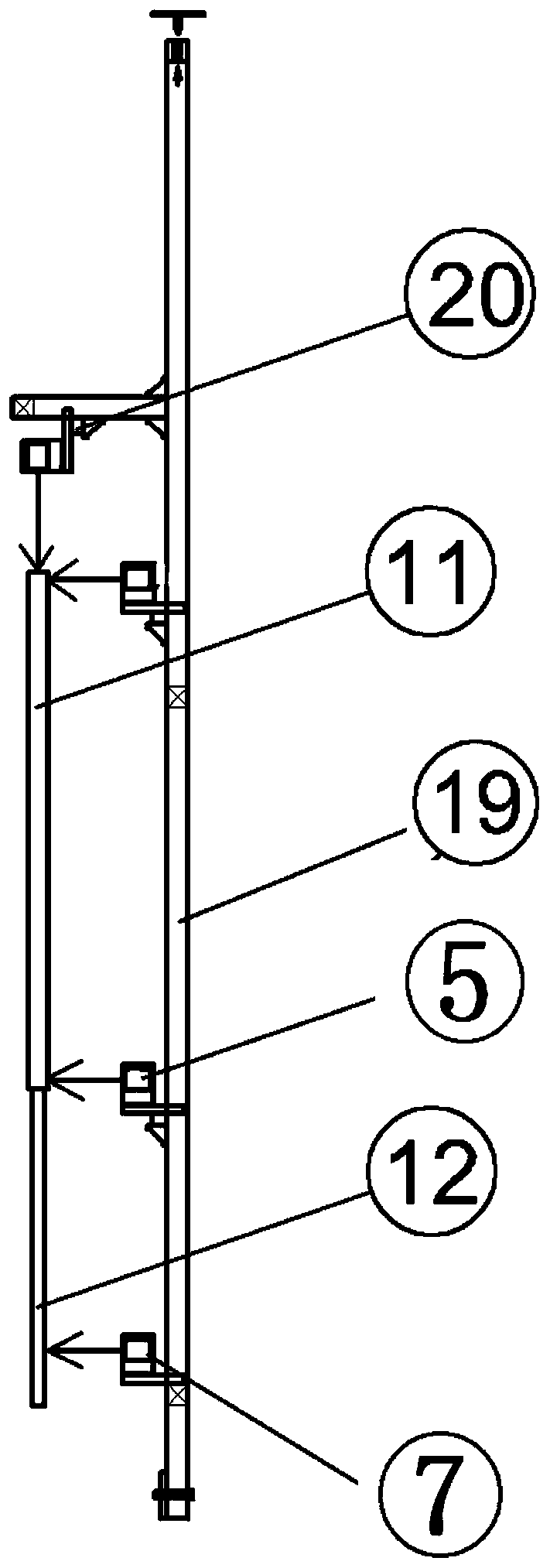

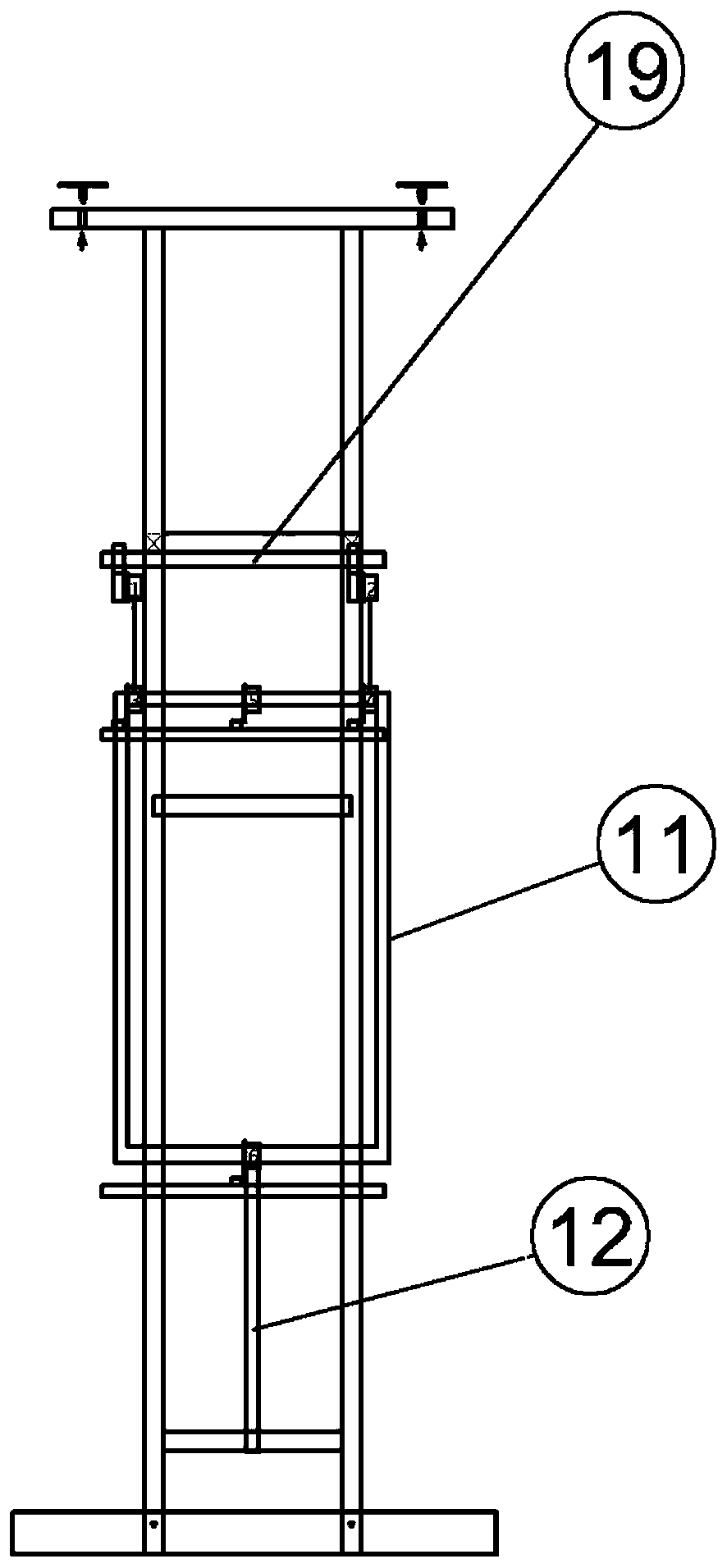

[0035] Such as figure 2 and image 3 As shown, the present embodiment provides a spraying hanger attitude laser detector, a spraying hanger attitude laser detector, including a test frame 19, a spraying hanger 11 and an electric control box assembly; Spraying the workpiece 10, the spraying workpiece 10 corresponds to the position of the spray gun 9 of the spraying robot 8; and the test frame 19 is arranged on the back side of the spraying hanger 11, and six lasers corresponding to the position of the spraying hanger 11 are installed on the test frame 19 Sensors, wherein the first laser senso...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com