A kind of potassium-based thermochromic film and preparation method thereof

A thermochromic, potassium-based technology, applied in metal material coating process, vacuum evaporation plating, coating, etc., can solve the problems of gap, low phase transition temperature, etc., achieve weight reduction, lower annealing temperature, and broaden the selection range effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

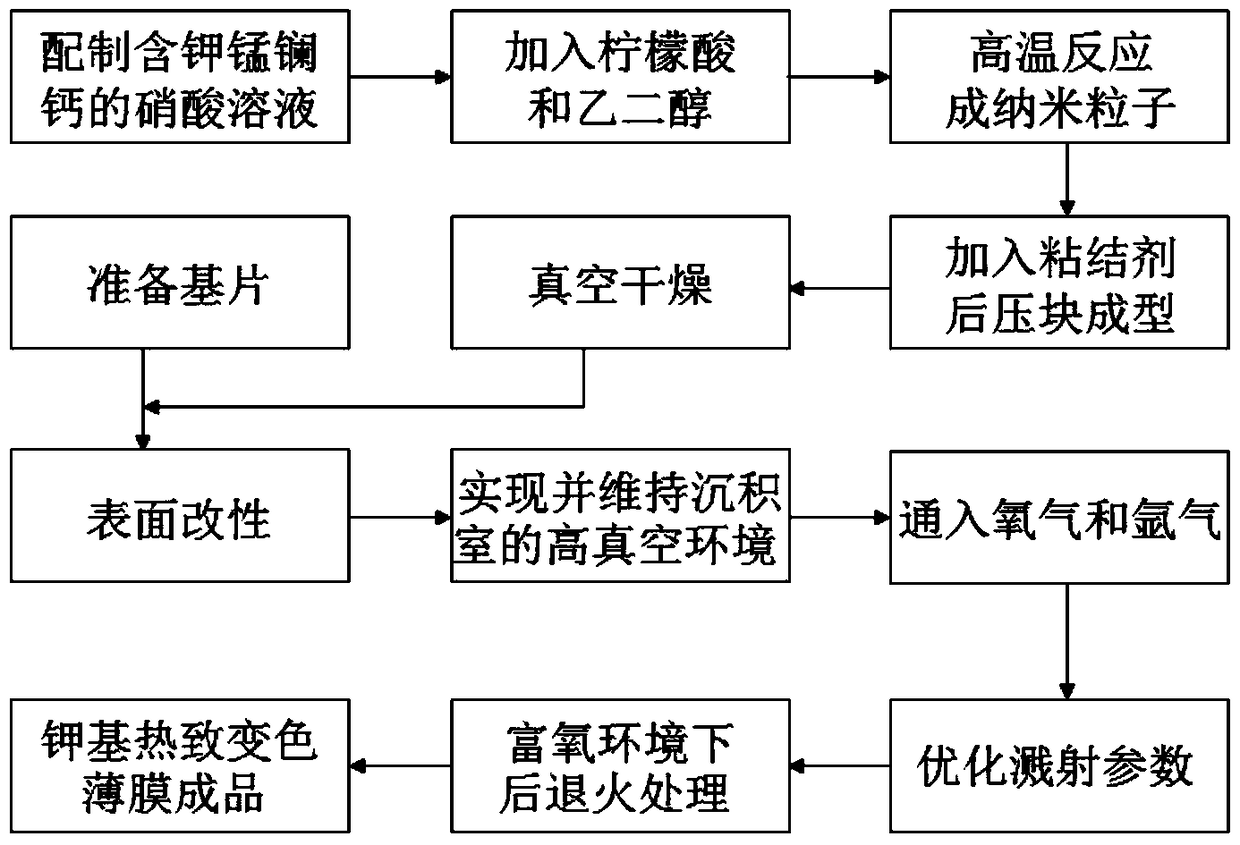

Method used

Image

Examples

Embodiment 1

[0029] 1. Mix 44.16% of the total mass of lanthanum nitrate particles, 2.18% of calcium carbonate powder, 1.51% of potassium carbonate particles, and 52.14% of manganese nitrate solution in dilute nitric acid solution, add 151.2 grams of citric acid and 10ml of ethyl alcohol Diol, react in a water bath at 80°C to obtain a wet gel, and pre-calcine at a medium temperature of 550°C and a high temperature of 950°C to obtain a dry powder.

[0030] 2. Fully mix the powder with 10% by mass of polyvinyl alcohol binder, then ferment and sieve at normal temperature to obtain the powder raw material required for briquetting.

[0031] 3. Weigh about 80g of powder, use a press to press it into a cylindrical block, and dry it under vacuum at 100°C for 16 hours to obtain a target.

[0032] 4. Set the oxygen content to 20% during deposition, and the power of the RF power supply to 80W, deposit the components in the target onto a 500μm thick monocrystalline silicon substrate, and anneal at 600...

Embodiment 2

[0034] 1. Mix 44.06% of the total mass of lanthanum nitrate particles, 2.9% of calcium carbonate powder, 1% of potassium carbonate particles, and 51.91% of manganese nitrate solution in dilute nitric acid solution, add 151.2 grams of citric acid and 10ml of ethyl alcohol Diol, react in a water bath at 70°C to obtain a wet gel, and pre-calcine at a medium temperature of 470°C and a high temperature of 900°C to obtain a dry powder.

[0035] 2. Fully mix the powder with 8% polyvinyl alcohol binder by mass, ferment and sieve at normal temperature to obtain the powder raw material required for briquetting.

[0036] 3. Weigh about 80g of powder, use a press to press it into a cylindrical block, and dry it under vacuum at 90°C for 14 hours to obtain a target.

[0037] 4. Set the oxygen content to 15% during deposition, and the power of the RF power supply to 70W, deposit the components in the target onto a 300μm thick YSZ substrate, and anneal at 500°C in an oxygen-enriched environme...

Embodiment 3

[0039] 1. Mix 43.96% of the total mass of lanthanum nitrate particles, 3.62% of calcium carbonate powder, 0.5% of potassium carbonate particles, and 51.91% of manganese nitrate solution in dilute nitric acid solution, add 151.2 grams of citric acid and 10ml of ethyl alcohol Diol, react in a water bath at 60°C to obtain a wet gel, and pre-calcine at a medium temperature of 400°C and a high temperature of 800°C to obtain a dry powder.

[0040] 2. The powder is fully mixed with the polyvinyl alcohol binder of 7% by mass, and then fermented and sieved at normal temperature to obtain the powder raw material required for briquetting.

[0041] 3. Weigh about 80g of powder, use a press to press it into a cylindrical block, and dry it under vacuum at 80°C for 12 hours to obtain a target.

[0042] 4. Set the oxygen content to 10% during deposition, and the RF power to 60W, deposit the components in the target onto a 200μm thick single crystal silicon substrate, and anneal at 400°C in an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com