Supporting structure for extremely-narrow coal pillar roadway driving along goaf and construction method of supporting structure

A supporting structure and coal pillar technology, applied in earthwork drilling, wellbore lining, tunnel lining, etc., can solve the problems of no public report on construction methods, loss of bearing capacity focus, roadway space cannot be maintained, etc., to achieve roadway maintenance volume Effects of extremely small, improved coal pillar recovery rate, and reduced roadway section convergence rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

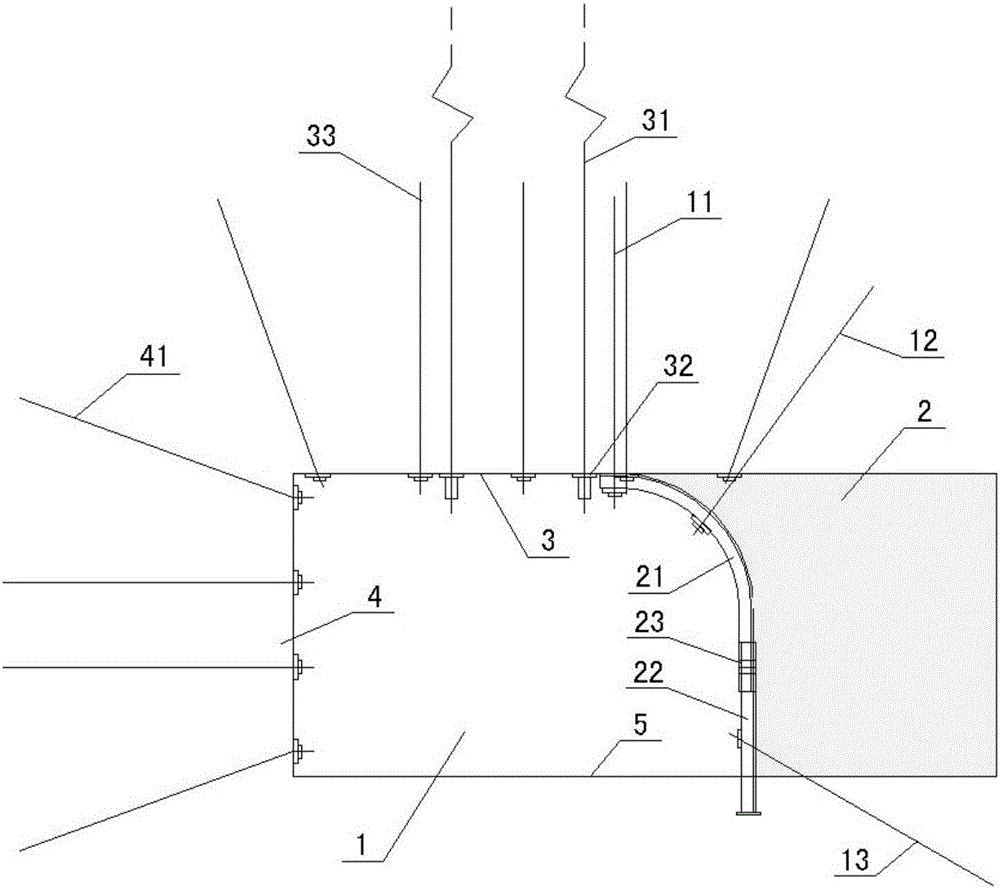

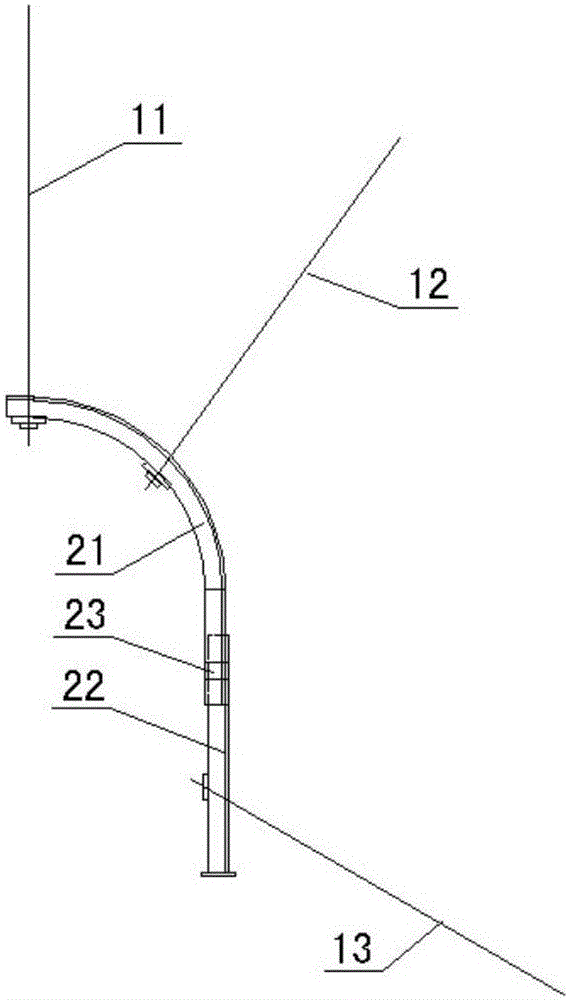

[0024] see figure 1 and figure 2 In this embodiment, gob entry with extremely narrow coal pillars refers to leaving 1-3m coal pillars 2 gob entry along the edge of the goaf in the adjacent section when the entryway 1 is excavated.

[0025] In this embodiment, the support structure for the gob-side entry of extremely narrow coal pillars is:

[0026] The roof of the roadway adopts the structural form of anchor beam net support, and the roof anchor cable in the anchor beam net support adopts a combined anchor cable. The channel steel beam 32 refers to the channel steel beam supported on the roadway roof 3 along the roadway excavation direction; For support, anchor cables 31 cooperate with longitudinal ceiling channel steel beams 32 for reinforced support. Wherein the roof anchor rod 33 adopts strong anchor rods such as Φ20×2400mm left-handed rebar, and the row spacing is 800×800mm; the anchor cable 31 is Φ22×7500mm, and the row spacing of the anchor cable 31 is 1100×800mm. T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com