A special tool for manual turning of steam turbines

A technology of manual cranking and special tools, which is applied in the direction of machine/engine, mechanical equipment, engine components, etc., can solve the problems of inaccurate results of centering, inconvenient cranking, etc., and achieves simple structure, convenient disassembly and assembly, Accurate and reliable results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

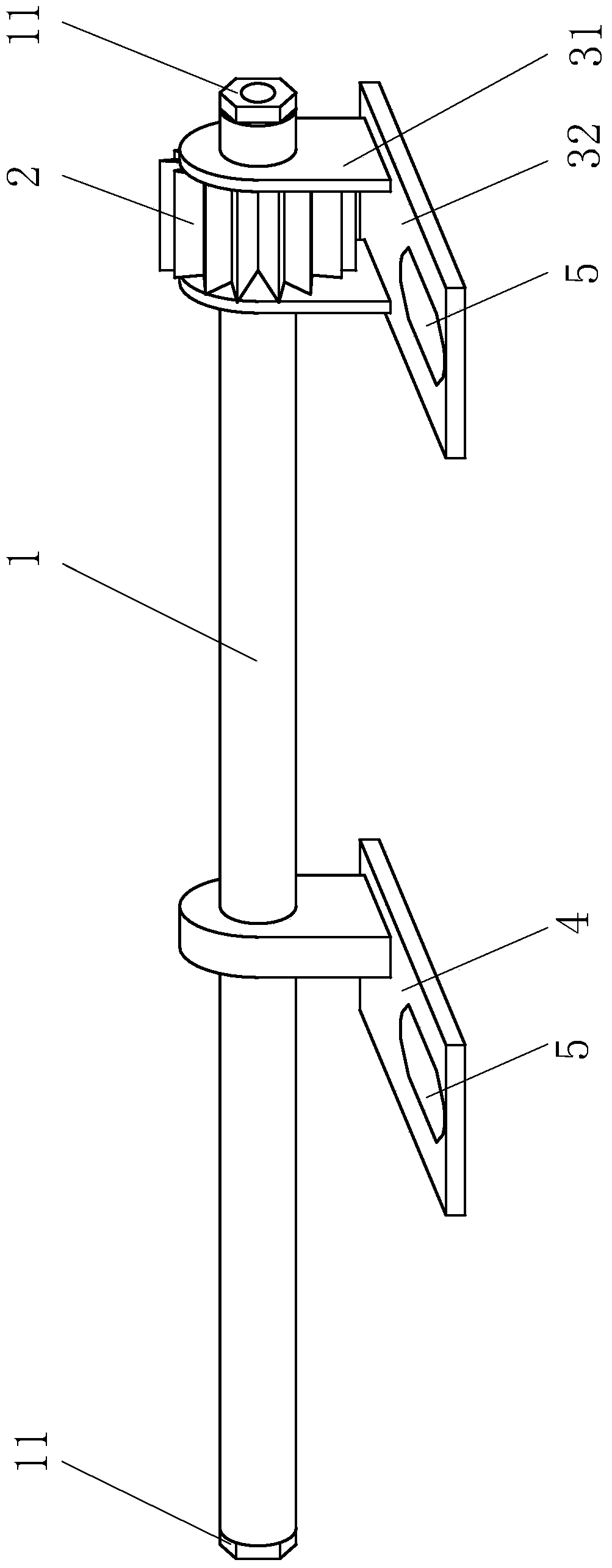

[0017] This embodiment provides a special tool for manual turning of a steam turbine, such as figure 1 As shown, it includes a handle 1, a spur gear 2 installed on the handle 1, a U-shaped perforated support 31 set on the handle 1 for fixing the position of the spur gear 2, and a U-shaped perforated support 31 fixed on the U-shaped perforated hole. The fixed base 32 on the support 31 and the sliding base 4 set on the handle 1 . The size of the handle 1 is φ51×1150mm.

[0018] In this embodiment, the sliding base 4 can slide along the handle 1 to adjust the distance between it and the fixed base 32 ; the positions of the spur gear 2 and the U-shaped perforated support 31 relative to the handle 1 are fixed. The fixed base 32 and the sliding base 4 are provided with a slot 5, the slot 5 is a rectangular round head slot, and the rectangular round head slot is used to fix the fixed base 32 and the sliding base 4 to other devices through bolts.

[0019] In this embodiment, a nut 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com